Twin Screw

Designed for process flexibility, the Alfa Laval Twin Screw Pump is built on a robust, reliable platform that meets stringent hygienic standards. It is capable of handling both product transfer and Cleaning-in-Place (CIP). Its low pulsation characteristics and excellent solids handling capability reduce the risk of product damage, thereby improving product quality. Maintenance is simplified and process uptime increased.

High and low viscosity liquids – all perfectly and reliably pumped

- Greater process flexibility

- Ease of service, increased process uptime

- Robust reliable design, reducing cost of ownership and increasing process uptime

- Improved product quality

- Exceptional hygiene and cleanability

Close at Hand catalogue

The hygienic equipment product catalogue "Close at hand" includes product leaflets, links to animations, brochures and lists for ordering purposes.

CAD portal

The Alfa Laval CAD portal is an essential platform for downloading detailed product information, 2D drawings and 3D product models.

Service

Our dedicated Global Service Network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment. We can work with you to integrate our services into an Alfa Laval Service Agreement for predictable and worry-free operations.

Learn more about our service offer Troubleshooting

Serial number search Find a partner

Please contact us with any queries or questions.

Visit the Application & Innovation Centre

Do you want to identify the optimal equipment for the job and discover tangible savings before deciding on upgrades? In the Alfa Laval Application & Innovation Centre, you can do just that.

Optimize™ by Alfa Laval

Optimize™ by Alfa Laval boosts your existing processes and enables up to 90% savings on water, energy and chemicals with only small and no-risk investments.

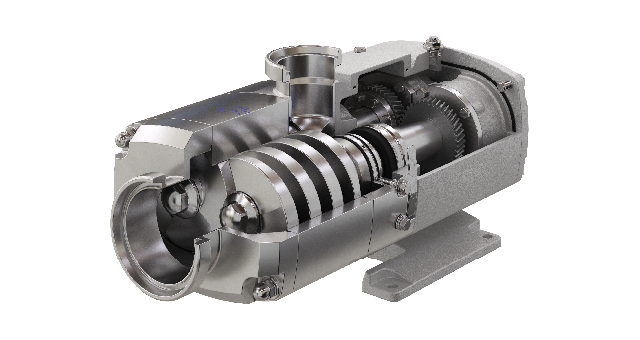

Twin Screw Pump technology

The Alfa Laval Twin Screw Pump combines process duties typically handled by positive displacement with CIP duties typically handled by centrifugal pumps. This provides a robust and reliable platform that offers greater process flexibility.

Process flexibility

Two-in-one operation provides easy handling of process media of varying viscosities as well as CIP fluids. This simplifies piping and pump control, cutting costs and minimizing contamination risks.

Superior suction performance with excellent lift capability and low NPSHr provides installation flexibility and increases product recovery.

Service and reliability

Quick, easy seal replacement with the twin screw pump pump in place is made possible, thanks to a cartridge seal with a truly front-loading, self-setting design. This maximizes process uptime and minimizes maintenance costs. An optional seal service kit program adds maintenance flexibility and cuts operating costs.

A robust, all stainless steel gearbox with timing gears located between bearings, provides an optimized bearing span. Balanced loading of the shaft assembly reduces vibration and noise, increasing component life and reliability.

The oil chamber design enhances bearing and gear lubrication, increasing bearing life and minimizing gearbox running temperature.

Easy access to timing gears, whilst the Twin screw pump is in position, simplifies the process of screw retiming; there is no need to drain gearbox oil or to remove the coupling and motor.

Operational safety

The Alfa Laval Twin Screw Pump features a clean, external stainless steel finish with profiled elastomers and mechanical seals fully surrounded by the product. Designed for maximum cleanability using FDA-conforming materials, the pump is both EHEDG- and 3-A certified.

The combination of optimized gearbox design and excellent hydraulic performance provides for quiet pump operation, minimizing noise emissions. Running temperature is also minimized, thereby increasing workplace safety.

An optional ATEX version enables use in hazardous zones.

Quick, easy maintenance

Minimize maintenance costs and maximize process uptime. Seal replacement with the pump in place is quick and easy, thanks to a cartridge seal with a truly front-loading, self-setting design. An optional seal service kit provides maintenance flexibility and cuts costs. Easy access to timing gears whilst the pump is in position simplifies the process of screw retiming without requiring drainage of the gearbox oil or removal of the coupling and motor.

Operating principle

The Alfa Laval Twin Screw Pump is a positive displacement pump. As the pump rotates, the intermeshing of the two contra-rotating screws, along with the pump housing, form volumetric chambers. These chambers fill with the pumped fluid and move it axially from the suction side of the pump to the higher pressure discharge side of the pump.

Product models

The Twin screw pump comes in twelve sizes – OS12, OS14, OS16, OS22, OS24, OS26, OS32, OS34, OS36, OS42, OS44 and OS46 – handling flow rates ranging from 0.1 to 134.3 m3/h, pressures of up to 16 bar, and solid sizes up to 43 mm.

Options

- Single mechanical shaft seal

- Single flushed mechanical shaft seal

- Double mechanical shaft seal

- Seal faces in silicon carbide/silicon carbide or silicon carbide/carbon

- Product wetted elastomers in EPDM, FPM or FFPM

- Diffusion hardened screws

- Heating jacket

- Rectangular inlet

- Hydrostatic testing with certificate

- Reversible flow

- Bottom inlet or outlet

- Wide range of port specifications

- Direct or geared motor

- ATEX version

- Multiple MEPS

360° Service and maintenance videos

You might also be interested in…

Subscribe near Newsletter

Stay updated on important sustainability issues and opportunities in your industry and processes!

Animations

Visit the animations site and take a look inside a product to see and understand how it works.