Engine power

Whether an engine power plant is small back-up facility or a plant that generates hundreds of megawatts, one wants to get the most from it. Doing so depends on the diesel engine or engines at its heart, but also on the surrounding equipment. Alfa Laval is a leading supplier of auxiliaries with a long history of serving engine power businesses, which means we understand the full scope of needs. Based on the plant’s unique setup and conditions, we can help in optimizing its energy production.

Optimize your power plant’s fuel line

If engines are the heart of a power plant, the fuel line is what keeps them going strong. Alfa Laval’s separators, fuel supply systems, pumps and other solutions are designed for years of reliability, so you might seldom think of them. But like fuels themselves, our technology and knowledge develop. We have answers to improve efficiency, lower OPEX, prepare for biofuels and more. Explore our equipment below – and talk to us about fuel line possibilities.

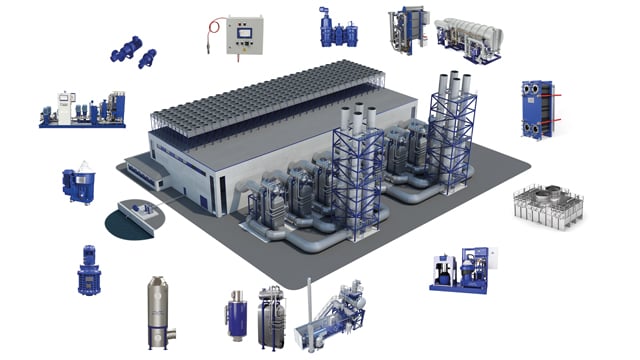

Alfa Laval at engine power plants

Alfa Laval equipment contributes to nearly all aspects of engine power plant operation, delivering high performance with low cost of ownership. Ideal for new plants, it can also be installed in existing plants as replacements and upgrades for major gains in efficiency. Using our solutions and knowledge can improve reliability, sustainability and more – including bottom-line performance.

Fuel and lube oil cleaning

Centrifugal separation is the most reliable and cost-effective means of purifying fuel and lube oil. Alfa Laval’s high-speed separators build on more than 100 years of separation experience, combining high separation efficiency and engine protection with true ease of use.

Biofuels

Biofuels can be used in diesel engines without major engine modifications, but they differ from conventional oils and must be managed with care. Alfa Laval’s deep insights and biofuel-ready separators can help you transition successfully.

Fuel supply

The Alfa Laval FCM 1.5 Oil provides flexible and future-proof fuel conditioning. Capable of handling up to four oil fuels, it safely and efficiently manages the changeover process. At all times and whatever the fuel, it ensures optimal cleanliness, pressure, flow and viscosity at the engine inlet.

Fuel and lube oil pumping

Developed with the marine industry in focus, Alfa Laval ALP three-screw pumps are designed for the lowest operating cost and the highest reliability. This makes ALP pumps the obvious choice for handling fuel and lubricating oils.

Oil viscosity control

Alfa Laval Viscochief 3 is a stand-alone modular system for automated control of fuel viscosity. Installed in a new fuel supply system or added as an upgrade, it presents a unique opportunity to control multiple fuel parameters with a single system.

Fuel and lube oil filtration

Alfa Laval Moatti self-cleaning filters provide high-performance filtration of fuel oil and lubricating oil – with virtually no pressure drop. Beside protecting engines from contaminants and debris, they have a cartridge-free design that minimizes waste.

Freshwater generation

Compact and efficient, Alfa Laval freshwater generators convert seawater into high-quality fresh water. Their effective desalination technology reduces energy use and related emissions, while smart features like non-glued gaskets make it easy to perform maintenance.

Heating and cooling

Alfa Laval gasketed plate heat exchangers draw on more than 100 years of innovation in heating and cooling technology. Compact, energy-efficient and resistant to fouling, they offer power plant owners the highest thermal performance while requiring a minimum of space and maintenance.

Auxiliary cooling

Alfa Laval’s auxiliary cooling solutions are customized to a plant’s operating conditions and requirements. Our wet surface air coolers (WSAC) use closed-loop cooling and condensing, while our hybrid air coolers (HYAC) combine traditional air cooling with closed-loop evaporative cooling.

Oily waste treatment

Our solutions for oily waste treatment not only maximize environmental protection but also minimize oil losses. Alfa Laval PureBilge cleans oily water to less than 15 ppm without filters, while Alfa Laval PureDry reduces sludge volumes – and can reclaim usable fuel.

Waste heat recovery

Optimized for the specific conditions at each power plant, Alfa Laval Aalborg waste heat recovery solutions increase fuel efficiency and plant efficiency overall. By recapturing the maximum amount of energy possible from the exhaust gas, they boost profits while shrinking CO2 footprint.

Auxiliary waste heat recovery

Waste heat recovery can encompass more than main engines. The Alfa Laval Aalborg Micro is a compact, lightweight solution for use after smaller engines and gas turbines. Suitable for diverse media, it supports power generation, process applications, district heating and more.

Crankcase gas cleaning

By removing 99.9% of the oil mist ventilated from the engine crankcase, Alfa Laval PureVent creates a cleaner plant environment and protects the health of plant staff. The performance of this unique centrifugal separator is unmatched by traditional cyclones, air traps or filters.

Product overview brochure

Alfa Laval solutions can provide reliability and efficiency in applications throughout your engine power plant. Download our product overview to explore the equipment we offer and the ways it can benefit your operations.