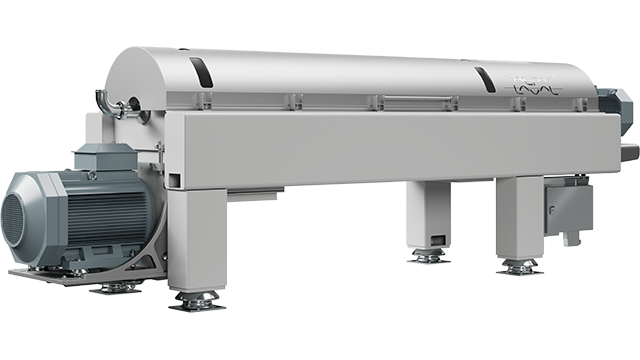

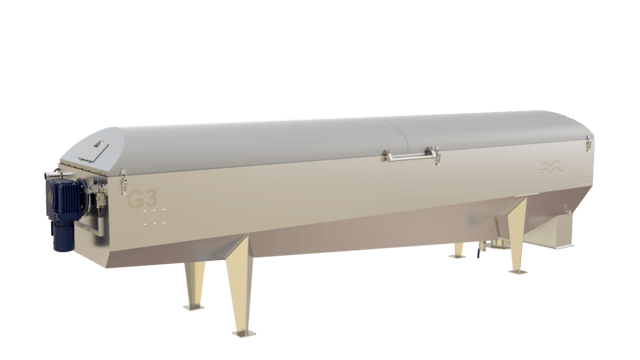

Aldec G3

The Alfa Laval Aldec G3 sludge dewatering centrifuge is the latest generation of sludge dewatering equipment for municipal and industrial wastewater treatment plants. It is designed to set a significantly higher standard for both process performance and environmental impact in sludge dewatering.

Experience the next level of performance with a groundbreaking sludge dewatering decanter

- Lower power consumption (which also greatly reduces CO2 emissions)

- 10% boost in processing capacity – or drier cake

- Reductions in life cycle costs

- More efficient bio-solids handling

- Better process monitoring and control

The advanced range of sludge dewatering decanter centrifuges is ideal for making significant contributions to a sustainable environment. Its innovative design delivers peak performance at all times while reducing total power consumption by up to 40%. This improvement leads to substantial reductions in CO2 emissions during the sludge dewatering process.

Sludge dewatering centrifuge - a set of innovative parameters

Alfa Laval's unparalleled sludge dewatering equipment has paved the way for a series of groundbreaking innovations, all based on proven technology renowned for its reliability. Together, these features ensure a unique combination of superior performance and lower energy consumption, resulting in reduced operating costs and benefits for the environment.

The smaller conveyor diameter of the Aldec G3 sludge dewatering decanter creates more space for liquid in the pond and allows for higher bowl wall pressures, resulting in either a drier cake or reduced polymer usage.

Patented Alfa Laval Power Plates effectively reduce the power consumption of Aldec G3 decanter centrifuges, making a big contribution to cost savings in sludge dewatering.

Each Aldec G3 sludge dewatering decanter is equipped with a PLUS control package as standard, pre-installed and tested with each specific unit. The combination of PLUS controls with the Aldec G3 sludge dewatering centrifuge ensures optimal performance while keeping installation, commissioning, operation, and maintenance costs to a minimum.

Sludge dewatering equipment highlights

- Patented Power Tubes for enhanced efficiency and reduced power consumption.

- SuperPond Design for optimal space utilization and improved separation performance.

- Durable Wear-Resistant Materials used in critical components for extended lifespan and reliability.

- Fully Open Feed Zone for superior separation and smooth operation.

- 360° Solids Discharge to prevent blockages and ensure continuous performance.

- Baffle Disc Technology for higher capacity and drier cake solids.

- Flexible Cone Configuration (Steep or Shallow) for effective separation of all types of slurry.

- Customizable Conveyor Designs tailored for different slurry types.

- Advanced Wear Protection Options for conveyor flights, catering to various processing requirements.

- Complete, fully enclosed Cleaning-in-Place (CIP) system for easy maintenance.

The features that make the difference

With over 60 years of expertise in solid-liquid separation, Alfa Laval delivers cutting-edge solutions to tackle sludge dewatering challenges. Engineered with patented Alfa Laval innovations, the Aldec G3 sludge dewatering decanter sets new benchmarks in efficiency, reliability, and serviceability.

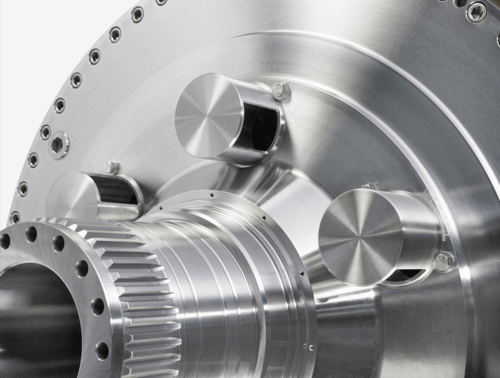

PowerTubes

Liquid outlet with pond depth regulation and energy recovery

PowerTubes adjustable outlets are designed to release the liquid tangential to the rotating direction, supporting the bowl rotation and thereby recovering energy, and minimizing power consumption.

SuperPond

Increased separation performance and energy efficiency

Increasing the pond depth inside the bowl creates a larger volume, leading to longer retention time and improved separation performance. The SuperPond design features a deeper pond and smaller solids outlet diameter, resulting in high solids dryness and clean centrate at high flow rates, as well as low energy consumption.

VecFlow™

Rotating feed zone

Low turbulence in the decanter centrifuge bowl is essential for high separation performance and low power consumption. The VecFlow™ rotating feed zone gives you maximum performance with minimal turbulence.

FlightGuard

Robust wear protection for conveyor flights

FlightGuard wear protection consists of tiles welded to the conveyor of your decanter centrifuge, providing robust wear resistance and prolonged uptime in highly abrasive applications.

FeedProtect

Feed zone with replaceable wear protection

The uniquely designed FeedProtect feed zone ensures gentle product acceleration and minimal turbulence, resulting in low abrasion and power consumption. The FeedProtect design is equipped with replaceable wear-protection liners, ensuring high uptime of your decanter centrifuge.

VecFlow™ Technology

Optimize your wastewater sludge dewatering and sludge thickening

VecFlow™ technology delivers outstanding performance in wastewater sludge thickening and dewatering. The unique VecFlow™ feed zone of Aldec G3 decanters minimizes turbulence and reduces power consumption by up to 30% compared to traditional decanter centrifuges.

Minimal turbulence for maximum performance

Aldec G3 decanter centrifuges equipped with VecFlow™ technology for sludge thickening gives you maximum performance with minimal turbulence. Alfa Laval’s unique VecFlow™ sludge centrifuge feed zone reduces turbulence by more than 80% compared to traditional decanter centrifuges and cuts acceleration power by 40-50%.

Gentle acceleration

A traditional feed zone injects the sludge radially into the decanter bowl, continuously disturbing the internal flows and causing turbulence. A VecFlow™ feed zone, on the other hand, gives the feed a completely different flow path since it accelerates the sludge tangentially when entering the bowl of the decanter centrifuge.

Sludge centrifuges with better separation performance

Apart from reducing total power consumption in sludge thickening, the low turbulence also improves separation performance. The separation is more effective than in a traditional decanter centrifuges, with less break-up of flocs. Additionally, the efficient acceleration to full speed reduces wear on the conveyor.

Cut OPEX

Depending on your specific sludge-thickening requirements, you may wish to minimize polymer consumption, increase the dryness of the cake or boost capacity. The high separation performance in thickening and low power consumption leads to a low total cost of ownership and very short payback times. You often get a full return on your investment in less than one year.

At the forefront of sludge thickening technology

PowerTubes feature on sludge centrifuges has become the preferred choice for wastewater plants around the world

The PowerTubes liquid discharge recovers kinetic energy from the effluent. By directing the flow tangentially as it exits the decanter bowl, the decanter bowl is pushed in the direction of rotation, causing a significant reduction in energy consumption.

Proven sustainability improvements with Aldec G3 decanter centrifuges

Aldec G3 sludge centrifuge is an excellent tool for improving your plant’s environmental sustainability

The lower power consumption leads to reduced CO2 emissions. The high dry solids content reduces transportation requirements and landfill volumes, alternatively fuel consumption in incineration ovens.

How does the sludge dewatering equipment work?

Separation takes place in a horizontal cylindrical bowl equipped with a screw conveyor. The feed enters the bowl through a stationary inlet tube and is accelerated smoothly by an inlet distributor. The centrifugal force that results from the rotation then causes sedimentation of the solids on the wall of the bowl.

The conveyor rotates in the same direction as the bowl, but slightly slower, thus moving the solids towards the conical end of the bowl. The cake leaves the bowl through the solids discharge openings into the casing. Separation takes place throughout the entire length of the cylindrical part of the bowl, and the clarified liquid leaves the bowl by flowing over power tubes into the casing.

Sludge dewatering equipment success stories

Related products for sludge thickening and dewatering

Contact us anywhere, anytime

Reliable operations start with efficient sludge dewatering. At Alfa Laval, we combine innovation, expertise and a global service coverage to help you increase uptime, improve performance and get the most from your investment.