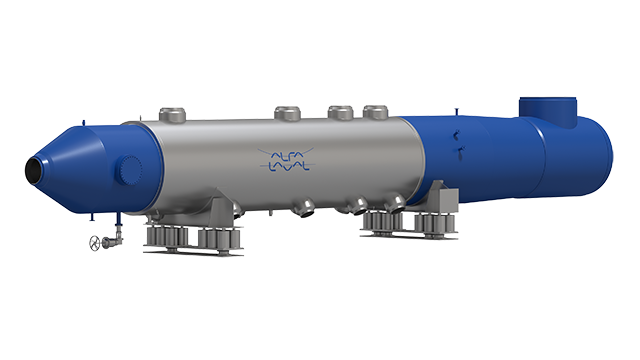

Process shell-and-tube heat exchangers

Alfa Laval customized process shell-and-tube heat exchangers are designed and built for the toughest applications in chemical processing industries, oil & gas production and power stations. These units maximize plant sustainability through low service requirements and exceptional reliability, resulting in competitive total cost of ownership and trouble-free operation. And with our extensive offer of services, we can help you optimize operation throughout the entire product lifetime.

Solid performance

- Fully customized to your requirements

- Maximum uptime under the toughest operating conditions

- High energy efficiency

- Low service requirements

- Extensive service network

With an Alfa Laval process shell-and-tube heat exchanger you get a tailor-made solution, optimized to your specific conditions. Our process heat exchangers are often used in production-critical positions under extreme conditions, and have a reputation for solid operating reliability and high performance.

Talk to an expert

We will be happy to discuss the benefits of an Alfa Laval Olmi heat exchanger and to show how we can help improve your operation.

Documents

Certificates

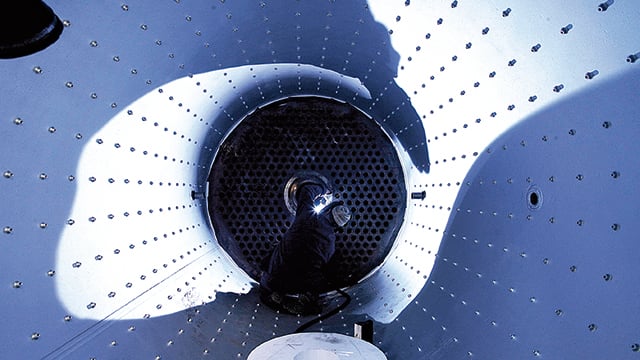

A complete service partner

With Alfa Laval as your partner you have full support from our experienced service teams around the world. We offer a wide range of services for process shell-and-tube heat exchangers, regardless of manufacturer. Our scope includes everything from regular maintenance to training, performance audits and upgrades.

Difficult times calls for new solutions

Just as an Italian Alfa Laval service team was finalizing preparations to go to Vår Energi's offshore platform in Norway to upgrade an Alfa Laval Olmi shell-and-tube heat exchanger, the Covid-19 pandemic hit Europe. But despite travel bans and national lockdowns, the team managed to complete the service in time thanks to new collaborations and a strong customer focus.

First-class service support

See how Alfa Laval’s service specialists helped technicians at the Midor refinery in Egypt to perform service on four feed/effluent heat exchangers.

Alfa Laval Olmi quench exchangers

Quench exchangers are core components in ethylene plants. These units operate under extremely tough conditions and are exposed to high flows of hot gas containing coke particles. Thanks to their unique designs, Alfa Laval quench exchangers are much more resistant to erosion, fouling, fatigue and corrosion than traditional quench exchangers.

Alfa Laval offers three different models of quench exchangers:

- Alfa Laval Olmi Primary Quench Exchanger S&T Type

- Alfa Laval Olmi Primary Quench Exchanger Double-pipe Type

- Alfa Laval Olmi Secondary and Tertiary Quench Exchanger