Aalborg XS-TC7A

The Alfa Laval Aalborg XS-TC7A is an efficient smoke-tube economizer. Easy to install, operate and maintain, it reduces the use of the fired marine boiler by recovering heat energy that otherwise would be lost through the exhaust gas. Thanks to the helix shape of its smoke tubes, the Aalborg XS-TC7A offers a large heat transfer area within a compact footprint. This enhances its performance and makes it the smallest smoke-tube economizer on the market.

The market’s smallest smoke-tube economizer

- Compact and efficient design based on helix smoke tubes

- Easy improvement of Carbon Intensity Indicator (CII)

- Short payback time (typically 1–2 years) through up to 25% fuel savings on the fired boiler

- Reduced wear and maintenance on the fired boiler

- Long service life thanks to self-cleaning Turbo Clean technology

Reduce fuel costs and emissions

The Aalborg XS-TC7A is part of Alfa Laval’s broad waste heat recovery portfolio, which builds on over 40 years of waste heat recovery experience. We take a holistic approach, helping you identify the optimal economizer setup for your particular vessel.

Our solution is always tailored to your steam requirements, the amount of exhaust gas and your vessel’s unique characteristics. It can include:

- Smoke-tube or water-tube economizers

- Single-inlet or dual-inlet solutions

- Compact economizers to minimize installation footprint

You can always count on a rapid return on your waste heat recovery investment. Our broad portfolio, combined with our deep expertise, is your assurance of the most cost-effective, reliable and energy-efficient waste heat recovery solutions.

In the coming years, the marine industry and ship-owners face big challenges as new environmental legislations have special focus on the reduction of emissions from fossil fuels. Therefore Alfa Laval has developed an efficient exhaust gas economizer - the Aalborg XS-TC7A (formerly MISSION XS) - utilizing the heat in the exhaust gas from the auxiliary engines during port stays, which will significantly reduce the oil consumption for the oil-fired boiler

Constructed with smoke tubes, the Aalborg XS-TC7A is an exhaust gas economizer for main diesel engines. It is available in two models, both of which have a vertical design and a high gas velocity that minimizes fouling.

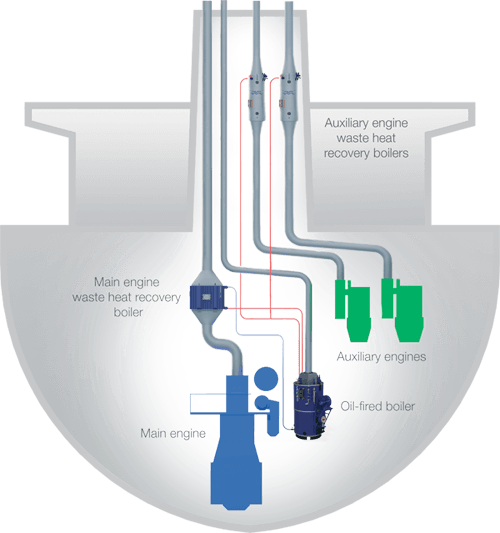

The concept of Waste Heat Recovery

In respect of environmental and operational enhancement products, Alfa Laval has recently introduced a new range of waste heat recovery (WHR) boilers mainly directed at the retrofitting market (but also well suited for the newbuilding market). This new product range will provide operational savings while improving the environmental profile of the ship and company.

For several decades, we have installed waste heat recovery (WHR) systems after the ships’ main engines and these units are to a large extent able to meet the vessels’ steam requirement during seagoing operation and for some installations also able to assist with the generation of electrical power.

The waste heat from the auxiliary engines has not been considered in the past, but it actually contains a large amount of energy which can be utilized to supplement steam requirements during port stays and - for some vessels - also during voyage. The WHR concept has been developed as a customized solution with special focus on energy generation compared to return on investment and has a very short payback time of down to 4-6 months in optimum cases, but normal payback time will be approximately 1 to 1½ year depending on the number of days the produced steam can be utilized (offset against the steam requirement from the oil fired boiler) and the redundancy requirements.

We offer a highly efficient and reliable concept based on well-proven and innovative solutions to ensure the best operation conditions and optimal return on investment. The design of the heating surface of the WHR boiler is the result of an enhancement of our unique technologies with a small footprint and the lowest possible weight to output ratio.

To ensure the most advantageous design, the WHR boiler concept will be specially tailored to the individual ship and engine design with due consideration of existing uptake back pressure, etc. The concept comes in two designs: one that requires a steam space in another boiler (e.g. in an existing auxiliary boiler) and one that has its own steam space.

Features and benefits

- Able to supply or support the steam demand during port stay

- Cost of steam production (energy) is nearly free

- Financially sound investment with very short payback time

- Adds a “green” profile to the ship

- Lower emission tax when finally agreed

- Less maintenance and lower operating costs for the oil-fired boiler

- How it works

How it works

Exhaust gas from the auxiliary engines has been an overlooked energy source. But because the cooler exhaust of long-stroke main diesel engines can be insufficient to support steam needs, it is becoming more attractive. Auxiliary engine exhaust gas can fulfill steam requirements during port stays or even en route. At today’s high fuel prices, the Aalborg XS-TC7A exhaust gas economizer has a typical payback time of 1–1.5 years.

-

Design pressure: 10 bar(g)

-

Capacity according to ship’s specification

-

Ability to support steam demand during port stays

-

Potential positive influence on Energy Efficiency

- Design Index (EEDI)

Ship types

- Container ship

- Tankers

Options

- With or without own steam space

- Resistance to dry running (within certain parameters) for continuous operation even when performing maintenance