Products and maintenance for refinery

Crude oil refineries want reliable and sustainable performance. With the broadest range of heat exchanger and separation technology, Alfa Laval provides the best products and solutions for your process. And with our global presence, we support you with maintenance and service worldwide.

Best sellers

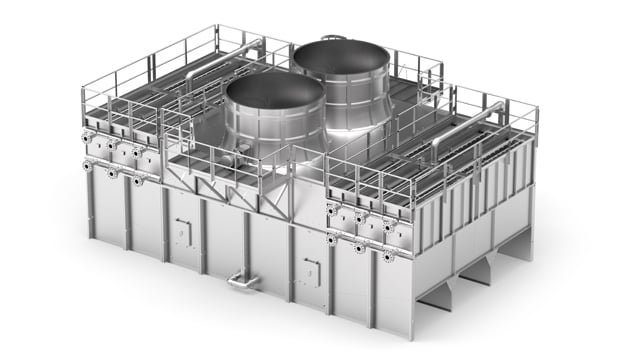

Compabloc

All-welded and fully accessible, the Compabloc can handle tough duties that need high pressures and temperatures. It can even cope with the most aggressive inlet media without compromising on fast and easy cleaning or inspection. Its flexible connection size and placement can manage asymmetric flows, and work in combination with a short plate construction to make the perfect solution for condensing and re-boiling duties.

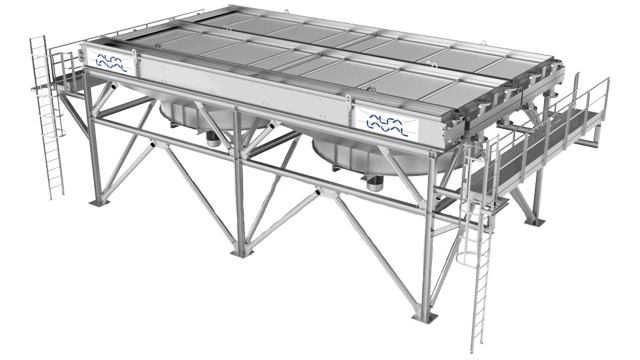

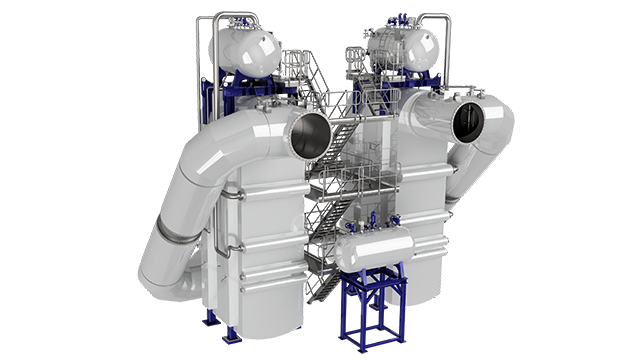

Packinox

Due to its many advantages, Packinox has become the industry standard combined feed/effluent heat exchanger in catalytic reformers and paraxylene plants. The potential OPEX reduction in these applications is significant, and choosing the right heat exchanger has a great impact on energy costs.

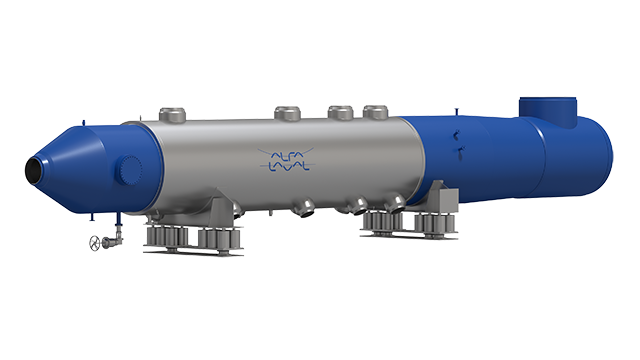

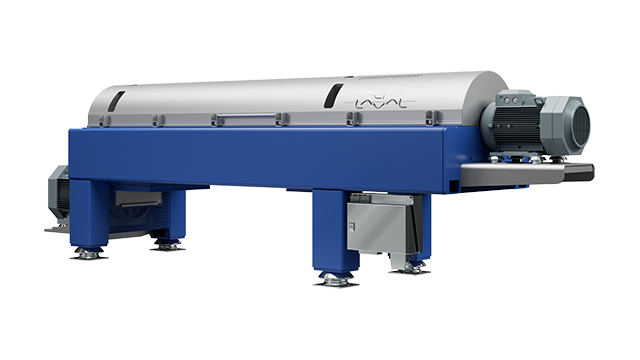

Spiral heat exchangers

The spiral heat exchanger is our no.1 problem solver. With its single-channel arrangement, this heat exchanger is self-cleaning and able to handle high-viscosity fluids. This design is easy to access for maintenance, making it the perfect option for low operating costs and optimized plant uptime. It also makes it an outstanding condenser that utilizes the lowest possible pressure drop. It can even be top mounted to reduce the installation costs even further.