Recycling

In a circular economy, recycling is the final phase of a product’s lifecycle, when the product can no longer be reused, serviced or repaired. Recycling lets us take advantage of the components and natural resources within the product and return them to production. However, today only a fraction of materials is recycled; the majority is sent to incineration or a landfill. Fortunately, emerging processes help commercializing the recycling of plastics, tires, textiles, batteries, municipal solid waste (MSW) and more.

Alfa Laval is here to help, with efficient separation and water management solutions for purification and concentration steps in your recycling process. These robust and proven technologies help reduce water consumption and the amount of non-recyclable waste. For cooling duties in processes such as pyrolysis and gasification, we also offer a wide range of heat transfer solutions. Keep reading to learn how we can support you to turn today’s waste into tomorrow’s value.

What a waste if we do not recycle it!

Using recycled materials instead of raw materials is an efficient way of both conserving natural resources and preventing pollution. To manufacture materials the second time around is much cleaner and less energy intensive than using raw materials.

There is an urgency to accelerate recycling technologies to defossilize the materials industries, and to preserve the valuable raw materials fundamental to our consumables. Today, more than 90 countries have set Net Zero targets with regards to greenhouse gas emissions. The targets put a very clear focus on developing new technology. Circular economy will play an important role in achieving them.

Plastic and derivates recycling

There are various recycling technologies. Key plastic recycling technologies include:

Mechanical recycling

The most common and widely used method for recycling plastic waste. It utilizes mechanical operations, such as sorting, shredding, and melting, to transform the waste into reusable materials, which primarily affect the physical form and size of the plastic waste. In a mechanical recycling process, the chemical structure of the plastic polymer remains intact, with no significant alterations to its chemical composition.

Advanced chemical recycling

Advanced chemical recycling is usually based on either pyrolysis, solvolysis or enzymolysis. It involves breaking down plastic waste into its chemical components or converting it into other valuable products.

Chemical recycling by solvents (Solvolysis)

A process that breaks down polymers into their individual monomers, enabling them to be polymerized to new chemical products. This technology can handle a broader range of plastic types, including complex and contaminated plastics that are difficult to recycle through mechanical means.

Bio-chemical recycling (Enzymolysis)

Biological recycling, also known as biodegradation or composting, involves the use of microorganisms to break down certain types of plastics into organic matter. This method is typically suitable for biodegradable plastics and can be utilized in specific composting facilities.

Thermo-chemical recycling (Pyrolysis)

A thermal decomposition process that converts plastic waste into fuel, such as oil or gas, in the absence of oxygen. It involves heating the plastic at high temperatures, breaking it down into its basic components.

Ash recycling

What is often considered waste today can become a valuable raw material in the future. For example, ash from incineration plants often contain high levels of salt that can be extracted and purified.

Sludge can be used as a raw material for concrete. Valuable metals that were previously too difficult to recover can be concentrated from diluted streams. Wastewater can be turned into fertilizer products. And these are just a few examples of the countless ways to use resources more efficiently.

With our unique solutions for heat transfer and separation, Alfa Laval can increase the performance of virtually any type of recycling plant or operation. We help you boost the production of your plant, taking care of valuable waste and completing the cycle.

Product overview

We offer solutions for efficient separation and water management in your recycling process, specifically for the critical purification and concentration steps. These robust and proven technologies reduce water consumption and produce less non-recyclable waste. For cooling duties in processes like pyrolysis and gasification, we offer a wide range of heat transfer solutions. Keep reading to learn how we can support you in turning today’s waste into tomorrow’s value.

Alfa Laval Zero Liquid Discharge (ZLD)

Alfa Laval ZLD systems are robust, compact solutions designed for the absolute minimization of liquid discharge in a wide range of industrial waste applications. ZLD systems optimize the efficiency of your water consumption via a combination of thermal solutions and separation technology, with the AlfaFlash evaporator at the core of the set up.

Alfa Laval separators

For centrifugal separation, Alfa Laval offers ideal options for any type of recycling. Matching the right equipment to the specifics of your process and feedstock is absolutely critical to the success of your production. We can support you with separation technology, expert guidance and service offering to ensure you get the ideal solution for long-term, reliable performance according to your particular demands.

Alfa Laval OLMI process gas boiler

An Alfa Laval process gas boiler is a very reliable solution for heat recovery duties in cooling syngas. For critical applications such as syngas production from waste plastics, an Alfa Laval OLMI process gas boiler is the ideal solution for operational peace of mind. You can count on fast ROI with a reliable tool for reducing the environmental impact of plastic waste.

Alfa Laval gasketed plate-and-frame heat exchangers

Energy efficiency is paramount to making recycling processes financially viable. Our gasketed plate-and-frame heat exchangers provide best-in-class performance and reliability in these applications. The Alfa Laval industrial line is suitable for a huge scope of duties from heating, cooling and heat recovery to condensation and evaporation.

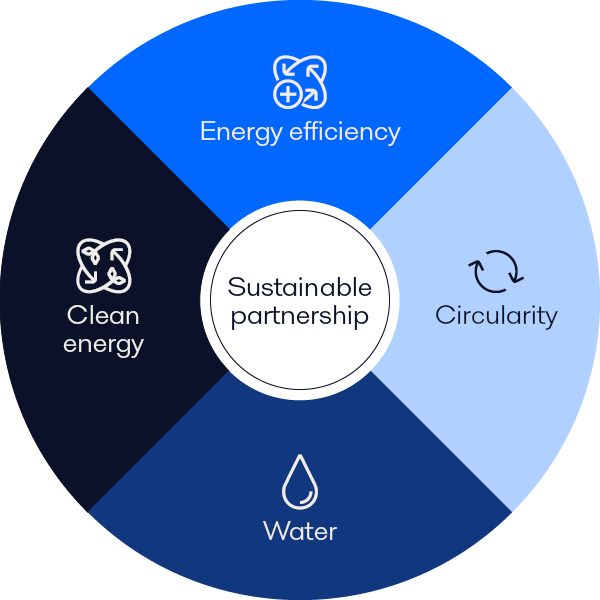

Energy efficiency

Clean energy

Sustainable partnership

Contact us to learn more

Contact us today for more information about our sustainable solutions