Gelatin and collagen processing

Gelatin and collagen are key ingredients in many applications in the food, pharmaceutical, and cosmetic industries.

Alfa Laval offers solutions for all key stages in a gelatin production process, enabling manufacturers to increase product quality, yield, and energy efficiency.

Contact our process experts for further insights on how you can profit from gelatin production.

Processing solutions for gelatin production

Gelatin clarification

Apart from gelatin, the water fraction also contains small concentrations of fat and suspended solids. Removing these contaminants from the solution is very important, and an Alfa Laval AFPX separator is the ideal tool for the job.

These highly reliable separators excel at removing fat and solids while providing great possibilities to finetune the separation process to meet the specific requirements at hand. The superior clarification efficiency reduces the load on the final clarification step, typically a filter press, thereby reducing the consumption of filter aids.

Purification and preconcentration

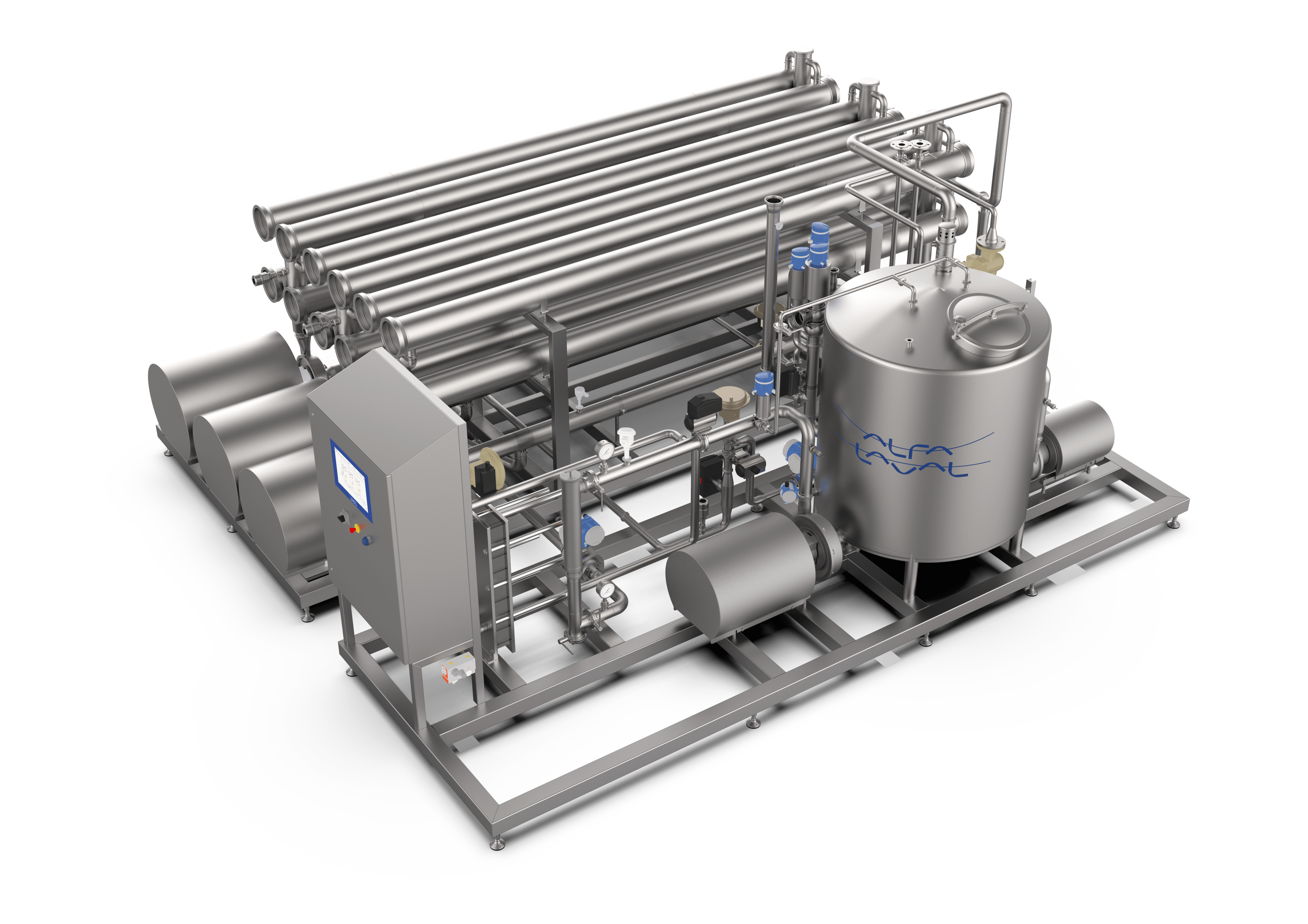

Following the clarification step, the gelatin solution is purified and preconcentrated in an ultrafiltration system, where salt and related substances are removed.

Alfa Laval ultrafiltration technology can be configured to comply with any customer’s specifications, and the final concentration depends on the gelatin type, the collagen processing method, the bloom figure, and the viscosity of the gelatin.

The filtration is a continuous process performed at a controlled temperature. Alfa Laval pHt membranes can withstand high process temperatures, enabling filtration at higher media temperatures, which, in turn, reduces viscosity and enables higher concentrations.

Final purification is done with ion exchange to remove odour and salts from the gelatin solution.

Concentration and sterilization

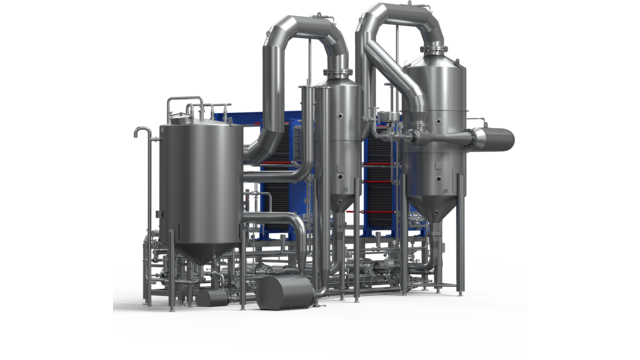

The final concentration takes place in an evaporation system.

The retention time and temperature profile play pivotal roles in shaping the final product quality. The product retention time in an AlfaVap evaporation system is very short, which, in combination with a very gentle temperature profile, leads to minimal protein deterioration, almost no discolouration, and superior product quality.

AlfaVap units are capable of handling fluids with significantly higher viscosity than falling film evaporators, allowing for more moisture to be removed in the evaporator. This, in turn, reduces the capacity requirements on the belt dryer and cuts costs for drying and cooling.

To eliminate spore-forming bacteria, the concentrated gelatin should be sterilized at temperatures around 130–140°C for 3–4 seconds. Alfa Laval provides sterilization modules utilizing either direct steam injection or indirect product heating. In both cases, the product retention time is extremely short, and the energy used in sterilizing the product is efficiently recovered for preheating the incoming product.

Combining membrane and evaporation technologies in the purification and concentration stages – and finding the right balance between them – makes it possible to optimize the total cost of ownership, the energy and water consumption, and CIP costs and to achieve the desired product quality.

Extruding, drying and packaging

Following the evaporation process, the gelatin is cooled in a scraped surface heat exchanger before being extruded onto the belt conveyor to feed the multi-stage air dryer.

Controlling the moisture and temperature during the drying process is crucial in order to maintain the bloom count in the gelatin. Alfa Laval’s Kathabar Liquid Desiccant technology plays a vital role in controlling the moisture level in the drying air.

After drying, the gelatin product is milled and packed.

Water recovery

Ultrafiltration permeate and condensate can be recovered using reverse osmosis and reused for extraction or CIP.

Complete service solutions for uninterrupted operations

With Alfa Laval as your service partner, you have direct access to qualified assistance and genuine spare parts whenever required. Our global network of service offices offers professional support ranging from troubleshooting and routine maintenance to advanced performance audits and predictive maintenance.

Through our remote services, we provide immediate assistance through digital channels. If you need on-site support, we will quickly dispatch field technicians to your site.

Alfa Laval offers full support for both individual components and entire process lines. Combining our reliable products and systems with Alfa Laval services is the best way to ensure performance and uptime.

For maximum return on your investment, we recommend entering an Alfa Laval Service Agreement. This fully customized service solution simplifies budgeting and maximizes performance and uptime. While you concentrate on your daily operations, we manage the planning, procurement, and execution of the required service measures.