Process water treatment and recovery

Significant volumes of valuable protein, fat, and oil can often be recovered from process-water streams, which are typically regarded as waste. This increases sales volumes and profits while reducing costs for wastewater treatment and waste disposal. In addition, recovering and reusing the process water significantly decreases water consumption.

Contact our application experts to gain insights on how to improve resource efficiency and plant sustainability.

Water treatment processes for meat and poultry applications

Alfa Laval offers a complete range of water treatment technologies, allowing us to deliver optimized solutions tailored to your exact needs and operational conditions. We offer equipment for:

- Fat and protein recovery from wastewater

- Water recovery

- Wastewater treatment

- Removal of protein from wastewater

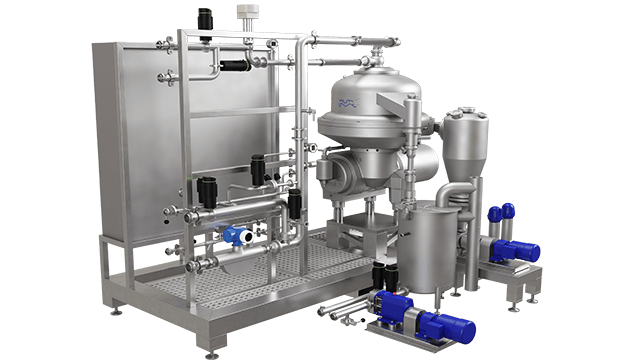

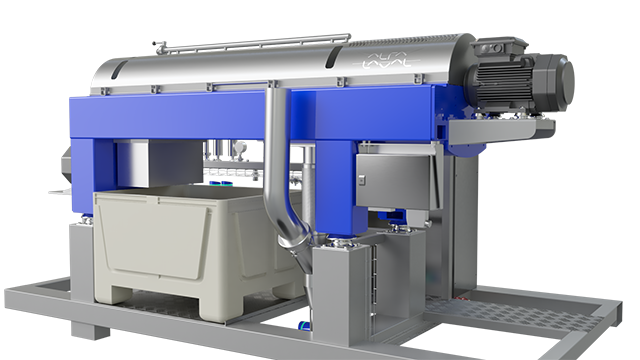

Recover valuable fat and protein from DAF water treatment

Most meat and poultry processing plants have installed a Dissolved Air Flotation system (DAF system) to reduce the BOD (Biological Oxygen Demand) load on their wastewater treatment plants. But instead of just disposing of the DAF skimmings, these can be further processed to recover protein and fat, which can be sold. This not only reduces the cost of sludge disposal significantly but also enables the recovery of most of the fats that would otherwise go to waste, representing a substantial economic value.

The defatted and dewatered solids can be dried for feed purposes or recycled. The quality of the recovered fat depends on both the freshness of the DAF skimmings and the flotation chemicals used. Typically, the recovered fat is of a lower quality. However, fresher skimmings are usually acceptable as a direct feed-grade product, whereas lower grades are only utilized in technical applications.

Alfa Laval can supply decanter solutions that enable fat recovery from the DAF skimmings. This fat can then be further refined in our high-speed solutions.

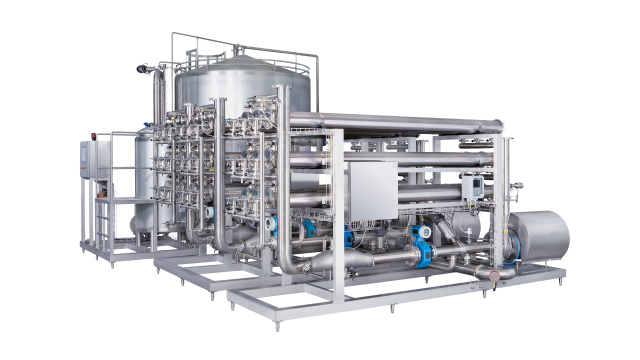

Recover water with membrane systems

Reverse osmosis (RO) membrane filtration systems can be used to recover water from evaporator condensates and help reduce the facility’s water consumption.

Depending on specific requirements and condensate composition, the permeate (clean) stream from the reverse osmosis system can be reused for flushing and CIP purposes or recycled into the manufacturing process.

In addition, it can be used to reduce the COD (Chemical Oxygen Demand) levels and mitigate odours in water sent to municipal wastewater treatment plants. Typically, the reverse osmosis system can recover 90-95% of the condensate as permeate.

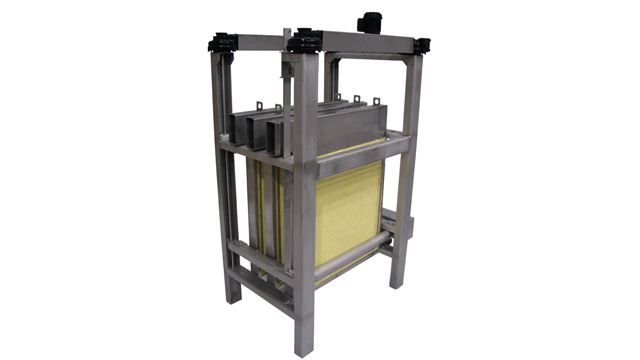

Wastewater treatment

Large-scale slaughterhouses often have dedicated wastewater treatment plants. Alfa Laval’s membrane bioreactor (MBR) units offer a compact and effective solution for treating effluents, enabling the reuse of the treated water within the plant or its discharge into a local river or lake.

These units are well-suited for cleaning water from meat and poultry plants, offering exceptionally low operating costs, reliable performance, and minimal maintenance. In addition, Alfa Laval decanters are a well-proven solution for efficient sludge dewatering.

Furthermore, Alfa Laval is equipped to deliver complete zero liquid discharge plants, integrating wastewater treatment with advanced evaporation technology.

Agri Beef cuts costs and carbon footprint with wastewater treatment upgrade

Learn how US beef producer Agri Beef has achieved substantial cost savings in energy and maintenance by upgrading their wastewater treatment plant with an Alfa Laval AS-H Sequencing Batch Reactor (SBR) system and an Alfa Laval AS-H Iso-Disc filtration system.

The upgraded facility treats the wastewater generated by the processing plant to quality levels that allow for safe discharge back into the environment. The revamp of the plant also enabled Agri Beef to start recovering biogas generated from the process. The recovered biogas meets 20% of the processing plant’s natural gas demand, thus reducing costs and limiting the overall carbon footprint.

Complete service solutions for uninterrupted operations

With Alfa Laval as your service partner, you have direct access to qualified assistance and genuine spare parts whenever required. Our global network of service offices offers professional support ranging from troubleshooting and routine maintenance to advanced performance audits and predictive maintenance.

Through our remote services, we provide immediate assistance through digital channels. If you need on-site support, we will quickly dispatch field technicians to your site.

Alfa Laval offers full support for both individual components and entire process lines. Combining our reliable products and systems with Alfa Laval services is the best way to ensure performance and uptime.

For maximum return on your investment, we recommend entering an Alfa Laval Service Agreement. This fully customized service solution simplifies budgeting and maximizes performance and uptime. While you concentrate on your daily operations, we manage the planning, procurement, and execution of the required service measures.