Q series

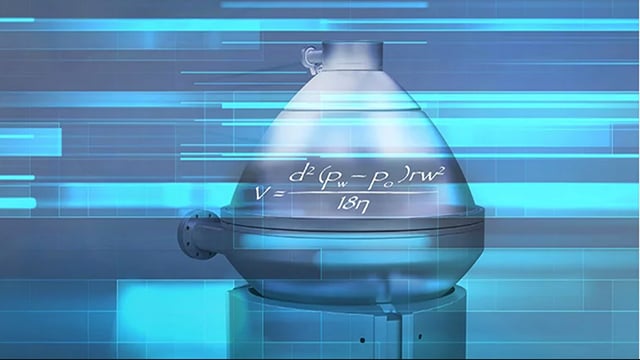

Our comprehensive dairy range includes the Alfa Laval Q517, a nozzle separator specifically designed to meet the demands of highly viscous dairy products, such as quark and yoghurt. The Q517 quark separator provides a unique solution for enhanced flexibility, reliability, and control over product quality.

Experience the benefits of Q series, efficient separation of quark and other viscous dairy products

- Efficient and reliable separation, as well as high yield

- Flow control and process flexibility

- High preservation of product quality thanks to a gentle inlet and outlet design that reduces drop splitting

- Easy to clean with discharge function that prevents nozzle clogging for efficient cleaning-in-place (CIP)

- Maximum reliability thanks to high-grade stainless steel that resists corrosion from chlorides and CIP chemicals

The Q517 nozzle separator excels in processing viscous dairy products like quark, Greek yoghurt, Turkish yoghurt, and cheese, ensuring gentle handling and efficient separation with superior quality.

Innovative features of Q series quark separator

Hermetic Design ™

Alfa Laval unique Hermetic Design™ ensures gentle and efficient dairy production. By maintaining the size of fat globules and preventing milk foaming, it guarantees consistent product standardization and exceptional quality. The airtight bowl enhances fluid dynamics, reducing power consumption by up to 60% compared to non-hermetic alternatives.

eDrive™

The Alfa Laval eDrive™ direct drive system provides an energy-efficient separator drive that has fewer moving parts compared to traditional gear- or belt-drive systems. Unlike most gear-drive systems with up to three shafts, the eDrive™ direct-drive motor has just one shaft. That translates into highly robust operation, more uptime, longer intervals between service, better energy efficiency, and reduced costs.

eMotion™

Alfa Laval eMotion™ is a unique energy-saving module, available as an add-on for many of Alfa Laval’s dairy separators. By creating a near-vacuum around the separator bowl, eMotion™ reduces air friction enough to improve energy efficiency with up to 25%. And there are additional benefits of eMotion™, such as reduced noise levels, lower cooling requirements, and improved cleanability.

UniDisc™

The Alfa Laval UniDisc™ boosts separation capacity by up to 30% with a hygienic, easy-to-clean design. Its built-in spacers allow more discs per stack, increasing surface area and enhancing performance or flow capacity.

Saving energy, cutting costs

Alfa Laval separators with Hermetic Design™ are the most energy-efficient on the market. When our unique eMotion™ technology is added, minimized air friction brings additional power reduction. Combined, our unique design and technologies can deliver up to 75% energy reduction compared to non-hermetic alternatives on the market.

Cutting back on water use

Alfa Laval dairy separators are self-cleaning. Thanks to Hermetic Design™ and our innovative UniDisc™ disc stack, cleaning is faster and uses less water and CIP liquid than traditional separators. Additional water savings can be made with eMotion™. By removing air around the separator bowl, eMotion™ reduces friction. Cutting the amount of water needed to cool the separator during operation.

Contact us to find our dairy partners

Alfa Laval separation equipment plays a critical role in all types of dairies, in all parts of the world. To best serve this market, we work with Tetra Pak as our Global Alliance partner and other selected process integrators in selected regions. Please contact us to connect to an Alfa Laval partner in your region.

Test, validate, and scale up your next separation solution

Whether upgrading your production line or running a proof of concept, Alfa Laval helps you choose the right separator solution with confidence. Simply get in touch to arrange a consultation and trial at one of our test centres, or to rent a unit for onsite testing.

The Separator Innovator

Would you like to know more about our innovations in separation technology? Click on the link below. Alfa Laval invented the first disc stack separator and has led the way in the development of centrifuge technology for over a century. We are glad to share with you the expertise we have gained along the way. Visit our Separator Innovator knowledge base to learn more about advancements in separation and the steps Alfa Laval is taking to continue revolutionizing the technology.