AFPX

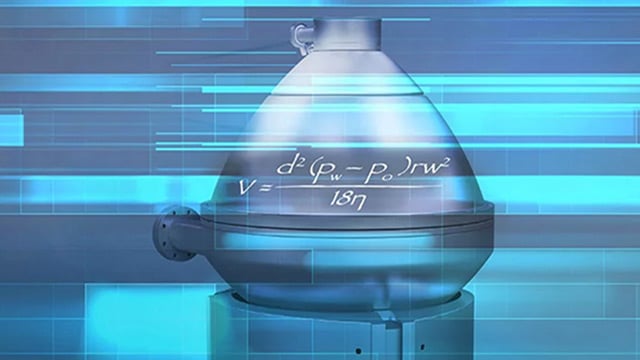

AFPX animal protein and fats centrifuges are used in meat and fish processing industries to purify and enhance the recovery of valuable protein fractions, fats, and oils. These robust and high-performing separators are specially designed for extremely demanding separation duties in order to meet the tough requirements of the food industry and exceptionally high hygienic standards. With an AFPX protein separator, you can achieve exceptional, high-quality fats and oils with 99.7% purity.

Achieve high animal protein and fat separation efficiency while keeping operating costs low

- Easy to operate and maintain

- Excellent wear and corrosion resistance

- Longer running times which ensures increased yield

- Cleaning in place (CIP) facility to keep the costs down

- Small footprint

The protein business is highly competitive, and to be profitable you need to maximize quality and yield while keeping operating costs low. At Alfa Laval, we have more than 30 years’ experience from designing rendering, fat melting and protein recovery separation systems and protein separators. We know how you can reduce your environmental impact and get the extra percent of product out of your raw material that make all the difference to your bottom line.

Why AFPX is the best option for animal protein separation and animal fat processing?

Key features of the AFPX range of protein centrifuges are their ability to handle high flow rates, high solids content and excellent separation performance. Due to these features, it is the ideal choice for tough conditions encountered in the animal and fish processing industries.

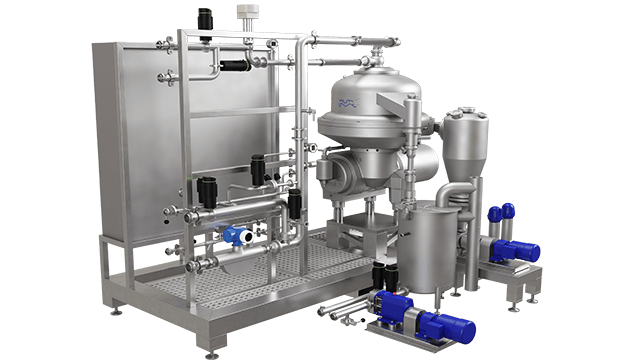

Depending on duty and feed composition, the AFPX protein separator can be configured in three different executions: concentrator, purifier and skimmer.

In addition, the AFPX combines a high G-force, high sludge capabilities and automated operation.

Applications - fat, oil and protein separators

AFPX protein centrifuge was designed to discharge solids intermittently, while at the same time separating two intermixed and mutually insoluble liquid phases of different densities. The centrifuges come in a series of optimized executions that are suitable for a considerable number of duties, including separating fish press water, stick water and extracts. Other applications include the purification of fish oil and liver oil, animal fat, peel oil, and similar products.

AFPX protein separators range

Depending on duty and feed composition, the AFPX protein separators can be configured in three different executions: concentrator, purifier and skimmer.

AFPX 200 protein separator

- Easy to operate and maintain

- Robust and reliable

- Wear resistant

- Excellent corrosion resistance

- Low moisture content in fat

- Flexible installation options

- Small footprint

- Plug-and-play possible

AFPX 617 protein separator

- Easy to operate and maintain

- Robust and reliable

- Wear resistant

- Excellent corrosion resistance

- Low moisture content in fat

- Flexible installation options

- Large solids handling capacity

- Plug-and-play possible

Test, validate, and scale up your next separation solution

Whether upgrading your production line or running a proof of concept, Alfa Laval helps you choose the right separator solution with confidence. Simply get in touch to arrange a consultation and trial at one of our test centres, or to rent a unit for onsite testing.

The Separator Innovator

Would you like to know more about our innovations in separation technology? Click on the link below. Alfa Laval invented the first disc stack separator and has led the way in the development of centrifuge technology for over a century. We are glad to share with you the expertise we have gained along the way. Visit our Separator Innovator knowledge base to learn more about advancements in separation and the steps Alfa Laval is taking to continue revolutionizing the technology.