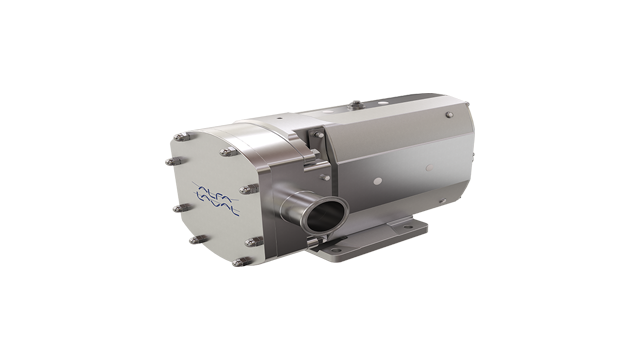

OptiLobe

Alfa Laval OptiLobe rotary lobe pumps are cost-effective alternatives for general applications requiring gentle product treatment and easy serviceability. Versatile, reliable and energy-efficient, these hygienic positive displacement pumps enhance both process flexibility and operational reliability.

Gentle, hygienic design with cost-effective simplicity

- Cost-effective, hygienic pump

- Optimal product quality due to gentle, low-shear operation

- Robust design for long service life

- Easy maintenance due to self-setting, front-loading seals

- Low total cost of ownership

Rely on corrosion-resistant, all stainless-steel Alfa Laval OptiLobe rotary lobe pumps to maximize process flexibility, minimize the risk of contamination and make washdown easy. Engineered for use within the food, dairy, beverage, and home and personal care industries, these positive displacement pumps conform to CE directives and EHEDG, 3-A and FDA hygienic standards.

Close at Hand catalogue

The hygienic equipment product catalogue "Close at hand" includes product leaflets, links to animations, brochures and lists for ordering purposes.

CAD portal

The Alfa Laval CAD portal is an essential platform for downloading detailed product information, 2D drawings and 3D product models.

Service

Our dedicated Global Service Network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment. We can work with you to integrate our services into an Alfa Laval Service Agreement for predictable and worry-free operations.

Learn more about our service offer Troubleshooting

Serial number search Certification

Please contact us with any queries or questions.

Visit the Application & Innovation Centre

Do you want to identify the optimal equipment for the job and discover tangible savings before deciding on upgrades? In the Alfa Laval Application & Innovation Centre, you can do just that.

Optimize™ by Alfa Laval

Optimize™ by Alfa Laval boosts your existing processes and enables up to 90% savings on water, energy and chemicals with only small and no-risk investments.

OptiLobe Pump technology

Take advantage of these technological features that enable Alfa Laval OptiLobe rotary lobe pumps add value to your processes.

- A robust platform, advanced seal design and heavy-duty, long-life bearings contribute to more uptime and higher productivity.

- Truly front-loading, self-setting seals with seal faces directly in contact with the media ensures superior cleanability and lubrication, improving seal life.

- Shaft support comprises of a rigid one-piece bearing housing and heavy-duty L10 tapered roller bearings with a minimum life of 20,000 hours. This contributes to stable shaft retention and more balanced loading, reducing the risk of pump head contact whilst decreasing maintenance requirements and increasing uptime.

- Optional heating/cooling front covers for processes, such as sugar solutions, butter and margarine, marmalades, body butter, gels and lotions, where products tend to harden at low temperatures.

Service

Factory-set shimming makes changing the rotor easy without the need to adjustment or retiming. Parts replacement, when required, is also simplified; high-precision components are interchangeable for pumps of the same size.

Product models

OptiLobe rotary lobe pumps are available with 10 different pump head displacements based on five different gearbox modules, flow rates up to 77 m3/h, differential pressures up to 8 bar, media temperatures up to 130°C and port size from 25 to 100 mm in diameter.

Operating principle

A gear train in the pump gearbox drives the rotors and provides accurate synchronization of the tri-lobe rotors.

The movement of the counter-rotating rotors creates a partial vacuum that allows atmospheric pressure or other external pressures to force fluid into the pump chamber. As the rotors revolve, an expanding cavity forms, filling with fluid. As the blades disengage, each dwell forms a cavity. As the rotor blades engage, the cavity diminishes and fluid is, displaced into the outlet port.

Options

Heating/cooling front covers for processes where products tend to harden at low temperatures.

Construction

Alfa Laval rotary lobe pumps are positive displacement pumps with rotor case, rotor case cover, rotors, rotor nuts, shafts, gearbox and shaft seals and elastomers. The pumps operate with no internal contacting parts in the pump head.

The OptiLobe can be supplied either as a bare shaft pump or mounted on a base plate complete with coupling, guard, gear motor and shroud for easy plug-and-play installation.

The standard materials of construction are 316L stainless steel for all wetted parts, all stainless-steel exterior, and EPDM for all product-wetted elastomers. EasyFit shaft seals are fully front-loading, and high-precision machine components are interchangeable for pumps of the same size.

In addition, Alfa Laval manufactures all pump parts, including the rotor case and high-precision rotors. This facilitates maintenance and results in full interchangeability of spare parts.

You might also be interested in…

Food Logic

Alfa Laval's hygienic equipment combines high performance with gentle handling to preserve sensitive ingredients and keep up with the food industry trends. The equipment addresses four key challenges; supplying food products to consumers at a competitive price, getting the most from raw materials, reducing waste and emissions, and delivering safe and hygienic food products.

Ten top tips - Rotary lobe pumps

Here are some tips and service videos to show how you keep your rotary lobe pumps in tip top condition

Subscribe near Newsletter

Stay updated on important sustainability issues and opportunities in your industry and processes!

Animations

Visit the animations site and take a look inside a product to see and understand how it works.