Southern California zeros in on circularity in wastewater treatment

Establishing a reliable, energy-efficient and viable water system is a top priority in Southern California, where water scarcity and rising demand are driving positive change. And for Orange County Sanitation District (OC San), this means increasing efficiency at key stages of the wastewater treatment process.

DATE 2024-11-29

OC San oversees the collection, treatment, recycling, and disposal of the wastewater generated by 2.6 million people, commercial and industrial sources, from a 1,240km2 area of central and northwest Orange County.

The company operates two wastewater plants, one in Fountain Valley and the second in Huntington Beach, where an extensive capital programme of projects to upgrade, improve and build climate resilience have been ongoing for several years.

One such project to boost the efficient treatment of the 268,219 cubic metres of wastewater that pass through the plant daily was completed in 2019 and involved the replacement of a competitive sludge dewatering technology with five Alfa Laval Aldec G3 decanter centrifuges.

“A key project driver was cake dryness,” explains Marc Perratore, Southwest Regional Sales Manager for Alfa Laval in the US. “The appeal of our G3 decanters was the 10 percent increased cake dryness and the lower power consumption of up to 40 percent.”

With a similar project also completed at the Fountain Valley plant, OC San cut the total volume of biosolids by a third – reducing the transport and management costs required for the 540 tonnes produced daily by around US$4 million per year and increasing the amount of water available for reuse.

“There is a shift, especially here in California, towards plants like these becoming central to resource capture and energy generation,” says Marc. “They are at the forefront and setting the tone for the entire country. Instead of treating wastewater and then finding a way to dispose of it safely, we are finding avenues to put it to good use.”

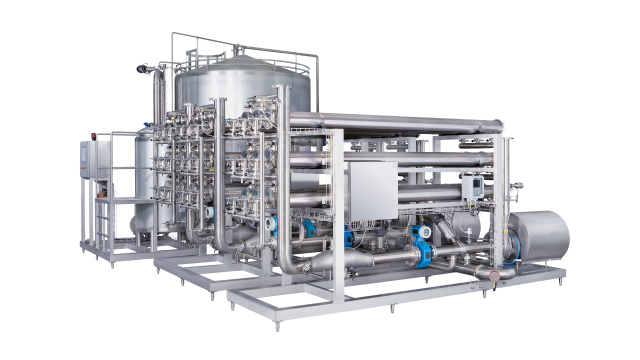

To that end, the treated wastewater from the decanters undergoes further treatment in a landmark initiative called the Groundwater Replenishment System (GWRS), a joint partnership between OC San and the Orange County Water District (OCWD), the world’s largest water purification system for indirect potable reuse.

Highly treated wastewater, which previously would have been discharged into the Pacific Ocean, now receives additional treatment via microfiltration, reverse osmosis and ultraviolet light before it is discharged to replenish the groundwater basin in Orange County – recycling 100 percent of OC San’s reclaimable flows and maximizing water reuse.

Energy generation is a key feature at the Huntington Beach site, where two of Alfa Laval’s spiral heat exchangers have been installed in an upstream process to produce biogas. The technology heats batches of sludge in anaerobic digesters, where it remains for 18-21 days and reaches temperatures of approximately 36°C (97°F). The methane biogas produced is captured, compressed, and used to fuel engine generators that produce electricity – supplying more than 60 percent of OC San’s overall energy needs.

“The plant generates an average of 7.1 kilowatt hours of energy every month,” says Marc. “That’s a net power saving of US$6.2 million that would otherwise need to be purchased from the power company.”

These projects form part of OC San’s current Capital Improvement Program, which has seen US$2.9 billion of investment over 10 years in upgrading, replacing and constructing new infrastructure to improve the wastewater treatment process in Orange County – increasing water recycling, energy generation and underpinning a reliable water supply that is fit for the future.

Highlighted technologies

Energy saving from technology shift to decanters: 40 percent

At Fountain Valley plant:

Efficient treatment of the 268,219 cubic metres of wastewater, enabling reuse

US$4 million reduction in operating costs

At Huntington Beach plant:

The capture of methane and use of the biogas to produce 7.1 kWh - or 60 percent of the plant’s energy consumption.