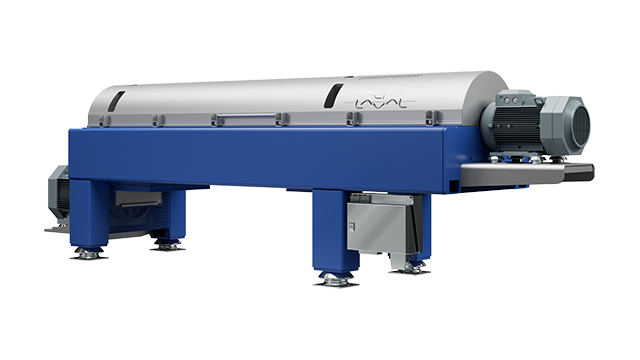

Decanters

Alfa Laval decanter centrifuges help you with solid-liquid separation within one single continuous process. Stand out from the competition with high performance separation that results in extracted / clarified products of excellent quality and higher commercial value. Make a difference as you recover valuable raw materials, reduce energy consumption and lower footprint and waste management costs with our industrial decanter centrifuge machines and services.

Make a difference to your business and the environment:

- High-performance separation, resulting in high-value products and low waste management costs

- Low energy consumption and carbon footprints

- Low maintenance costs thanks to continuous operation, high-grade machine materials, smart design and well-thought preventive services

- Low capital cost/capacity ratio

- Wide-ranging feed variations and controllable performance

Solid-liquid separation is a common manufacturing process in countless industries, and Alfa Laval has over 60 years of experience using decanter centrifuges to meet this requirement. Decanter centrifuge operation makes use of centrifugal force – the effect can be up to 4000 times greater compared to using gravitational forces.

Alfa Laval uses high-grade stainless steel for all parts in contact with the solid-liquid separation process to prevent corrosion. High-stress rotating components are machined from high-strength centrifugally cast stainless steel, ensuring uniform, flaw-free castings and weld-free components for maximum strength, reliability, and long service life. Wear-prone areas, such as the feed zone, solids discharge output zone, bowl, and scroll, are protected by abrasion-resistant materials tailored to each industrial process. Continual refinement of the seal technology used in Alfa Laval decanter centrifuges is ensured by our technological resources for superior performance.

Applications

Food and beverages

- Brewery

- Casein, lactose, and cheese fine recovery

- Coffee and tea

- Distilleries

- Juices

- Plant-based drinks

- Plant-based proteins

- Starch

- Wine

Life science and biotech

- Fermentation

- Biomass separation

Oils, fats, and animal proteins

- Avocado oil

- Fish processing

- Insects

- Olive oil

- Palm oil

- Rendering

- Seed oil

- Surimi processing

Biofuels

- Bioethanol

- Biodiesel

- Biogas

Wastewater

- Industrial wastewater treatment

- Municipal wastetwater treatment

- Potable water treatment plant

Energy

- Ground engineering

- Mineral exploration drilling

- Mining and tailings

- Pulp & Paper

- Zero Liquid Discharge

Success stories of our decanter centrifuges in the food industry

Success stories of our decanter centrifuges in the water industry

The features that make the difference

Everything you need to meet your challenges today – and tomorrow

Packed with features unique to Alfa Laval, our decanter centrifuge designs offer improved efficiency, reliability, and serviceability across the energy, biofuel, food, water and waste industries. Alfa Laval's branded features are engineered to meet your specific needs, ensuring optimal performance and sustainability.

TrueStainless™

Stainless steel for long-lasting hygiene

TrueStainlessTM ensures solid stainless steel is used for the frame and other key parts of your decanter centrifuge that may be in contact with corrosive atmospheres, leading to optimal hygiene and longer equipment life.

PondCtrl

Adjustable pond depth control during operation

Fast and accurate adjustment of your decanter centrifuge pond depth, ensuring optimum conditions for maximum separation performance, cleanability and easy start-ups.

PowerTubes

Liquid outlet with pond depth regulation and energy recovery

PowerTubes adjustable outlets are designed to release the liquid tangential to the rotating direction, supporting the bowl rotation and thereby recovering energy, and minimizing power consumption.

FlightGuard

Robust wear protection for conveyor flights

FlightGuard wear protection consists of tiles welded to the conveyor of your decanter centrifuge, providing robust wear resistance and prolonged uptime in highly abrasive applications.

EasyLift

Spring loaded cover, that simplifies servicing

The patented spring-loaded hinged design makes it easy to open even the heaviest cover by hand. This also helps ensure quick, safe access for maintenance and service of your decanter centrifuge.

Alfa Laval offers tailored testing capabilities to ensure the highest separation efficiency and scalable results

Founded in 1883, Alfa Laval has led the way in centrifugal separation technology with continuous breakthroughs, including our high-performance decanter centrifuge. Leveraging our industry know-how and specialist process experience from around the world, Alfa Laval provides professional guidance throughout the entire testing process to guarantee the best solution for each application, achieving unparalleled cost and sustainability advantages.

From small-scale onsite pilot testing to scalable production, experience the convenience of a compact, modular, plug-and-play skid mounted unit. Watch the video to learn more about our reliable decanter centrifuge equipment, available for purchase or rent.

How does a decanter centrifuge work?

What happens during solid-liquid separation using our decanter centrifuge? Subject to centrifugal forces, the denser solid particles are pressed outwards against a rotating bowl wall, while the less dense liquid phase forms a concentric inner layer in a decanter centrifuge. Different dam plates are used to vary the depth of the liquid – the so-called pond – as required. The sediment formed by the solid particles is continuously removed by the screw conveyor, which rotates at a different speed than the bowl. As a result, the solids are gradually “ploughed” out of the pond and up the conical “beach”.

The centrifugal force compacts the solids and expels the surplus liquid. The dried solids then discharge from the bowl. The clarified liquid phase or phases overflow the dam plates situated at the opposite end of the bowl. Baffles within the centrifuge casing direct the separated phases into the correct flow path and prevent any risk of cross-contamination.

The speed of the screw conveyor may be automatically adjusted by use of the variable frequency drive (VFD) in order to adjust to variation in the solids load.

Benefits

What are the benefits of decanter centrifuges compared to other types of separation equipment?

Faster separation in single continuous process

Our horizontal centrifuges separate solids from one or two liquid phases in one single continuous process in a continuous, high-speed process. This enhances productivity and thus, profitability.

Wide-ranging feed variations and controllable performance

Alfa Laval centrifugal decanters are designed to handle a wide range of solid particles with diameters from 5 mm to a few microns.

Our industrial decanter units can also handle slurries with a solid content from as low as 0.1% w/w to more than 65% w/w.

Controllable centrifugal forces and other specific configuration details mean process optimization according to your specific requirements and goals, such as end-product of high market fit at the lowest possible costs.