Steam and heat generation

For over 100 years, Alfa Laval Aalborg marine boiler systems have been meeting the needs of heat consumers on board. Whether providing steam, hot water or hot thermal fluid, they deliver uncompromising reliability and efficiency. Better still, they offer flexibility, safety and peace of mind on your fleet’s decarbonization journey. More than just today’s standard, Aalborg boiler solutions – and the expertise behind them – are the answer to thermal needs when moving to tomorrow’s fuels.

Efficient and future-ready technology

- Solutions for steam, hot water and heating thermal fluid that are built on decades of application experience

- A fired boiler platform for operation with oils and biofuels – plus an additional fuel of your choice, implemented today or tomorrow

- Opportunities to produce steam by using shore power or surplus electricity on board – including hybrid and hybrid-ready boiler options

- Innovative waste heat recovery solutions that use reclaimed energy to generate steam – and can further improve the efficiency of fired boilers

- Comprehensive boiler services, ranging from onboard repair to performance optimization

No matter what fuel you use today or how you plan to meet tomorrow, Alfa Laval Aalborg boiler solutions are ready to support your goals – reliably, effectively and over the long term.

Fuel-flexible and future-proof marine boiler solutions

Alfa Laval Aalborg boilers have been instrumental in the move to more sustainable fuels. They were the first marine boiler solutions for use with LNG, and today they’re being installed as the first marine boiler solutions for use with methanol. Thanks to a uniquely flexible boiler platform, they can also be ready for tomorrow – whenever you’re ready to take the next step towards decarbonization.

Technology

Fired boilers on the path to zero carbon

Today’s Alfa Laval Aalborg OL, OS-TCi and OC-TCi boilers can be fired with both traditional oils and biofuels. In addition, they can be configured for one other fuel option: LNG, methanol or ammonia (currently in pilot stage). With a further hybrid option, they can even be equipped for combustion-free steam production, using shore power or surplus electricity when available.

Your options can be implemented from the start. But we can also prepare your boiler for a later upgrade, including space for future connections and components. With our flexible boiler platform, we can easily build tomorrow’s choices into today’s boiler design.

Electric, hybrid and hybrid-ready boiler options

As shore power becomes widely available, you have opportunities to avoid direct emissions in port. The Aalborg electric steam boiler offers a dedicated solution, and new Aalborg OL, OS-TCi and OC-TCi boilers can be configured as hybrid boilers with an additional electrical connection. They can also be installed hybrid-ready, with all preparations necessary for adding electricity later.

By taking advantage of surplus electricity on board, these boilers can even reduce emissions at sea. On LNG carriers and FSRUS, for example, extra power created by the gensets during boil-off gas (BOG) management can be turned into useful steam.

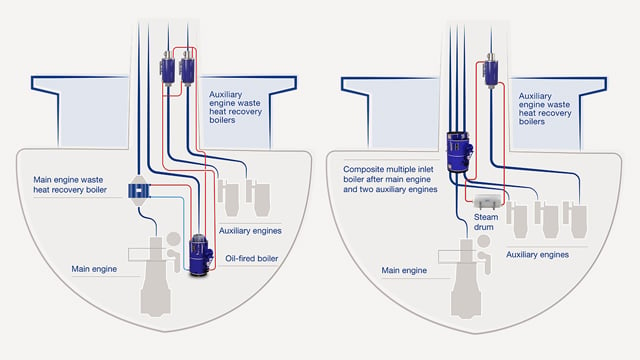

Fuel-saving waste heat recovery

Our boiler expertise can also be found in our wide portfolio of waste heat recovery solutions. Alfa Laval Aalborg economizers produce steam or hot water by reclaiming exhaust gas heat, and they can be used after both main and auxiliary engines. Besides reducing fuel costs, they significantly reduce emissions and improve CII.

With 40+ years of waste heat recovery experience, we take a holistic approach that ensures the optimal economizer setup – even as a retrofit. By maximizing steam production, you can not only meet heat consumer needs but also generate clean electrical power with the Alfa Laval E-PowerPack.

Complete and integrated steam solutions

Finding the best solution for your steam needs means looking at your vessel and its operations as a whole. Boilers and economizers can be integrated in multiple ways, for example to optimize the total efficiency of the steam plant or to secure full steam plant redundancy. Using options like the compact and versatile Alfa Laval Aalborg Micro economizer or the Alfa Laval E-PowerPack with Organic Rankine Cycle (ORC) technology, we can provide a complete solution that meets steam requirements while minimizing energy loss, fuel costs and emissions.

To explore the possibilities for your vessel, simply get in touch.