2016-05-31 Product news

Alfa Laval launches Fully Automatic Plate Press Washer

At the IFAT 2016 exhibition in Munich, Germany, from May 30 to June 3, Alfa Laval – a leading global provider of solutions and services for the water and waste treatment – introduces a new, fully automatic washing machine for its fully mechanised plate press.

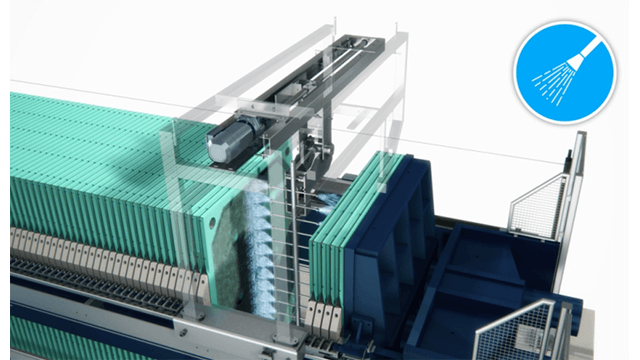

Alfa Laval has recently launched the new AS-H Fully Automatic Cloth Washer as an option for the Alfa Laval AS-H Fully Mechanised Plate Presses with side bar design. They are especially suited for high capacity, continuous dewatering in municipal and industrial applications, where a very high level of dry solids of the cake is of paramount importance. Plate presses are the best technology for solids capture > 99%. Alfa Laval’s fully mechanised plate press offer maximum degree of automation, also with extremely sticky filter cake.

The new enclosed stainless steel washing machine cleans the filter cloths of the plate press utilizing high pressure water at up to 100 bar. It works in conjunction with the automated plate separator of the plate press.

“To continue working efficiently, the cloth of the filter plates needs cleaning at regular intervals. This can be done either mechanically or manually,” says Paul Baggaley, Business Development Manager, Plate Press Technology, Alfa Laval Ashbrook Simon-Hartley. “Manual washing can be very time consuming and laborious leaving the plate press out of operation for up to a complete shift. With fully automatic washing the filter cloths are precisely cleaned over the full filtration and gasket surface much more efficiently than cleaning by hand”. When the plate press is equipped with the Alfa Laval AS-H Fully Automatic Cloth Washer, the entire cleaning process is done much faster without any need for operator intervention. The machine automatically separate the plates, and double acting arms wash two plates at a time.”

The fully automatic cloth washer is especially suited for large capacity plate presses, and can be retrofitted to existing plate presses.

During the automatic washing as well as the fully mechanised dewatering process, the operator safety system based on infrared light automatically stops the operation of the plate press, if hands or other objects move into the safety area. Washwater, cake and filtrate from the dewatering process are gathered in the mechanised, double acting hydraulic drip trays for discharge.

“For plants that need high dewatering capacity and have focus on efficiency, labour costs and maintaining throughput capacity the Alfa Laval AS-H Fully Mechanised Plate Press with the new Fully Automatic Cloth Washer it the perfect choice. They offer continuous, highly efficient operation with low manpower requirements as all main operational steps are fully mechanised”, Paul Baggaley concludes.

Alfa Laval also offers semi-mechanised plate presses and manual plate presses for pilot and lab tests.