Midwest ethanol producer realizes multiple benefits with Alfa Laval WideGap

Situated at the cross-roads of two rural highways, this ethanol producer is located in a small rural town in the US’s Midwest. The plant produces ethanol, a clean-burning, high octane transportation fuel and has a capacity of 135 million gallons per year. The facility utilizes corn/milo to produce ethanol via natural fermentation to produce fuel grade ethanol for blending with gasoline and other motor fuels. In addition to ethanol, the plant produces approximately 320,000 tons of dried distiller’s grains with solubles (DDGS) which is marketed to livestock and poultry producers as a value-added nutritional supplement as well as corn oil and carbon dioxide

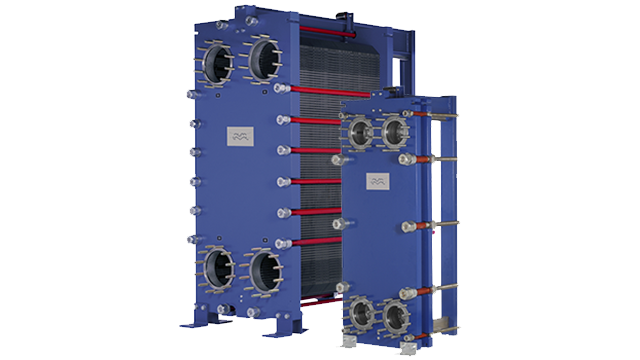

DATE 2025-01-24Like other ethanol producers, this plant identified the mash train as one of the limiting factors in achieving optimal operation. They also needed to achieve better pressure drops as well as better beer temperatures at increased flow rates – and their current equipment was not getting the job done. Their existing plate-and-frame heat exchanger design utilized 8/12" connections, 7mm/7mm gap spacing, with effective surface area of 16.8 ft2 per plate. They knew they could do better – and that’s when they turned to Alfa Laval for a more superior solution.

Alfa Laval WideGap – ideally suited for the bioethanol industry

Alfa Laval experts recommended their WideGap gasketed plate-and-frame heat exchanger, an ideal solution for fluids containing coarse particles or fibrous material, The wide gaps between its plates allow fibres and particles to easily pass through the heat exchanger with minimum clogging and maximum process uptime. The design helps prevent fouling and is also ideal for heat recovery in the beer-mash interchanger position due to the larger surface area per plate (20.78 ft2 per plate). Beer from the fermenters needs to be heated prior to the distillation step. Mash from the cooker needs to be cooled prior to fermentation. This is where the beer-mash interchanger is used to reclaim the energy from the cooker.

WideGap reduces cleaning frequency, increases productivity and reduces energy costs

Alfa Laval replaced one existing heat exchanger with an Alfa Laval WideGap 350X unit. Larger 11mm/11mm gaps between plates in the WideGap helped minimize clogging and reduced cleaning frequency and costs, resulting in process uptime and increased productivity. The wider plate gap also reduced the pressure drop which allowed for more passes in the unit, leading to 10°F hotter beer temp exiting the interchanger. Superior heat transfer efficiency also helped reduce overall fuel costs. Because of its counter-current flow, the WideGap was able to heat the cold stream to a temperature very close to that of the entering hot stream, maximizing energy recovery. This ethanol producer estimated an annual energy savings of $150k per year. Sceptical at first, the producer only converted one of their mash trains to the WideGap to test the technology. After one year of data to prove out the design, the other mash train was upgraded to the Alfa Laval WideGap. And finally, they found the WideGap easier to maintain and easier to service with a better hanger and tie bolt system for opening and closing the units. A two-part oven cured epoxy glue system for the gaskets also helps lower maintenance costs.

Highlighted technologies

Download customer story

Tags

All