Reduce risk of contamination in ice-cream tanks

What are some steps to ensure safety and quality in your ice-cream manufacturing process?

DATE 2023-11-28

In ice-cream production, it is essential to ensure proper fat crystallization and hydration of functional ingredients. To achieve that, the ice-cream mix after pasteurisation is usually kept under slow agitation for 4-24 hours.

This means the ice-cream mix is highly sensitive to contamination at this stage, especially if there were any residue left from previous batches. At the same time, the high fat content, sticky consistency and particles such as chocolate flakes and fruit bits can make cleaning of the tanks and mixers additionally difficult.

What are some of steps to ensure safety and quality to your ice-cream product?

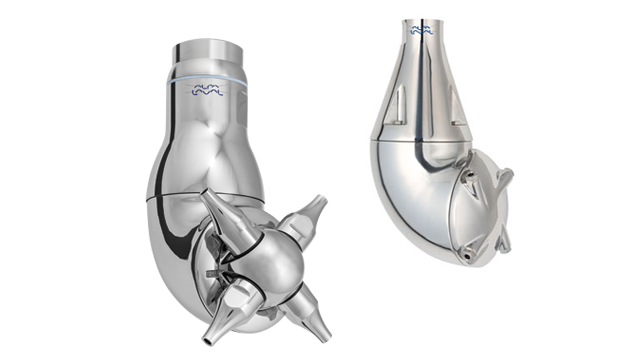

Frederic Liot, a 30-year veteran in the food industry and Global Business Development for Food at Alfa Laval, tells us more about how the right agitators and cleaning equipment can provide a healthy plant output and profitability at the same time.

Read full article published on Cleanroom Technology here.