Why do industrial plants need zero liquid discharge systems?

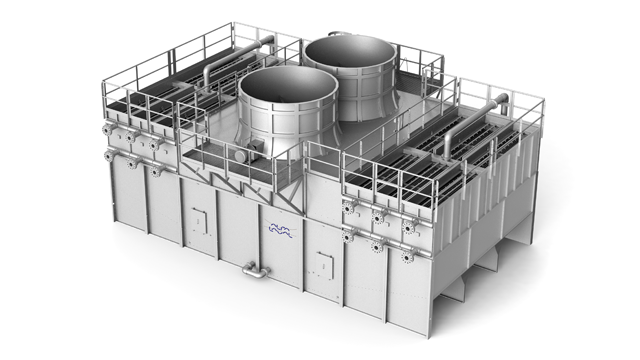

Industrial processes require energy, raw materials, and water. These processes generate products, waste and wastewater. Water management strategies, such as zero liquid discharge or ZLD, can minimize freshwater intake, recover valuable by-products, reduce costs, ensure compliance with environmental regulations and enhance the sustainability of overall plant operations.

DATE 2024-07-25

No industrial wastewater discharge into the environment

ZLD systems treat wastewater by recycling, recovering and reusing treated wastewater for industrial purposes. Evaporation is an economical and environmentally safe way to minimize wastewater. High-quality recycled water can be recovered from the wastewater for process reuse or beneficial discharge.

By concentrating the wastewater as much as is practical for a given application, the amount of wastewater can be reduced. Minimizing the amount of water in the waste cuts disposal costs since there is minimal solid waste and maximum treated water for process reuse. In some cases, valuable resources are recovered from the waste, increasing plant revenues.

Compact size, lower installation costs

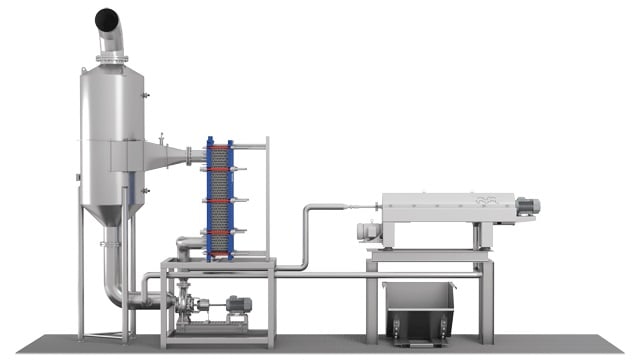

Robust and reliable, the Alfa Laval ZLD systems are plate-and-frame heat exchangers more compact than comparable shell-and-tube systems with equivalent capacities. This translates into a very high surface-area-to-volume ratio and lower overall installation costs due to less foundation, smaller building, and less onsite installation costs. It also speeds the time to get this modular system up and running.

More uptime and less cleaning

Keeping heat exchangers clean is key to overall ZLD performance and maximizes run times between cleaning. The Alfa Laval ZLD system uniformly induces high velocity and turbulence across all heat transfer surfaces. This self-cleaning effect keeps suspended solids recirculating and prevents them from accumulating on the plate surfaces. It also helps maintain the viscosity of shear-thinning fluids, reducing pumping energy costs.

Easy to clean: Flexible, adaptable and accessible

ZLD applications tend to be high fouling and require periodic mechanical cleaning. Alfa Laval’s gasketed plate-and-frame heat exchangers provide easy access to all heat exchanger surfaces for cleaning and inspection. Plates can easily be added or removed after installation to adapt capacity. Plate configuration can be modified if process fluids prove to be different than expected in the original design. Both plates and gaskets can be provided in a range of different materials suitable to a specific application. Flexible and adaptable, Alfa Laval ZLD systems are easier to clean than shell-and-tubes, maximising uptime and overall capacity.

Reduce risks by learning big on a small scale

Alfa Laval has three levels of analysis and testing available to help define the characteristics and challenges of your ZLD application. Alfa Laval can help you analyze your wastewater and, with the help of computer modelling, predict evaporator recovery, boiling point elevation, and fouling potential at your plant. Take advantage of benchtop testing to confirm physical properties such as density, viscosity, boiling point elevation, condensate quality, and evaporator recovery. Or conduct pilot tests to estimate evaporator performance criteria such as heat exchanger fouling and run time between cleaning cycles. A good understanding of the composition and physical properties of the wastewater is key for selecting and configuring the right treatment technology.