Revolutionary solution boosts Singapore’s world-leading sustainable water drive

In a nation famed for its ground-breaking water management, Alfa Laval has emerged as a leading player with the delivery of innovative treatment technology that promises to help meet Singapore’s major supply challenges. The country is gearing up for significant residential and industrial developments, and needs a major infrastructure upgrade to ensure holistically integrated supply, catchment, and treatment operations for its scarce water resources, to continue to supply a growing population.

DATE 2025-01-21

Step forward Alfa Laval, who have beaten the competition to win a contract to work with the Public Utilities Board (PUB), Singapore's National Water Agency, to overhaul the Kranji Water Reclamation Plant (KWRP), a vital part of the network that treats 350,000 m³ of water per day.

Alfa Laval’s dedicated team in Southeast Asia have worked tirelessly with contractors Sanli M&E Engineering to sell a combined drum thickener and decanter solution at the site.

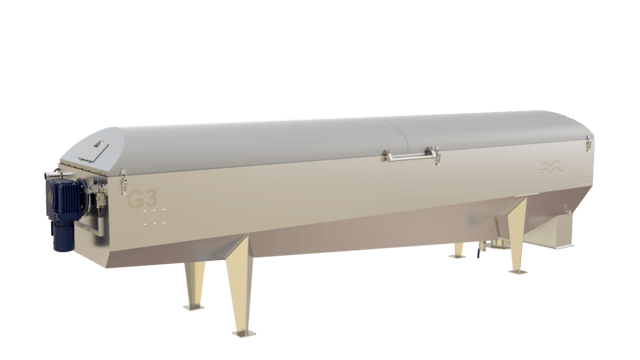

Firstly, four rotary drum thickeners (RDTs) have replaced the six ageing centrifuges at KWRPT, and so transformed the sludge-thickening stage of the treatment process, which had previously taken up 10% of the plant’s energy consumption. Given the new ALDRUM G3 Mega Duo RDTs use 20 times less energy than the old centrifuges, this energy-efficient, compact, and green solution represents a major sustainability boost for PUB.

To complete the overhaul, Alfa Laval also transformed the stage of the sludge dewatering process. After the thickening stage, the sludge goes to the digestion process for stabilization and biogas production and then goes on to dewatering. Here three Alfa Laval Aldec 105 decanter centrifuges have replaced the three competitor centrifuges to complete the dewatering process. The dewatered sludge (cake) is then used for incineration at sludge incineration facilities (SIFs) to generate electric power. The resultant ashes are sent to Singapore’s only operating landfill site on Pulau Semakau.

Based on analysis made by customer, the total cost of ownership (life cycle cost 15 years) for the RDT solution is about three times lower when compared with centrifuges – 9.5m Singapore Dollars versus 3.3m Singapore Dollars – which is significant and is expected to boost the implementation of this technology.

The process in detail

The thickening process starts with sludge and polymer being pumped via patented mixing valves into the flocculation reactor, where flocculation of the sludge takes place. This process helps to create stable flocs, intensify the process, and reduce polymer dosage. The flocculated mixture is then directed to Alfa Laval drum thickeners, which thicken the sludge from a concentration of 0.4-0.5% to 5-6% dry solids for waste-activated sludge, and from 2.5-3% to more than 8% dry solids for primary sludge. The drum thickeners operate in parallel, and the resulting sludges are mixed in a tank. This significantly reduces the volume of the thin sludge (up to 10 times less, depending on sludge type), optimizing further sludge processing and decreasing the hydraulic load exerted on the anaerobic digesters. The residual slurry, known as digestate, contains around 3.5% dry solids and is generated from the anaerobic digestion process. This digestate is subsequently dewatered using decanter centrifuges downstream in the process, a prime example of process optimization.

The four RDT units – ALDRUM G3 Mega Duos for thickening – work alongside three newly supplied ALDEC 105 decanters for further dewatering to deliver a neat, innovative and combined solution from Alfa Laval that has even raised eyebrows in a go-ahead, water-astute country like Singapore.

Bringing the latest advancements in water treatment technologies to Singapore, following months of close collaboration with various stakeholders, is a heartfelt achievement,” says Ray Tan, Alfa Laval’s Regional Sales Manager for Malaysia and Singapore. “In Southeast Asia, there is a growing emphasis on both effective and environmentally friendly solutions. Product knowledge alone is insufficient unless it is supported by a holistic view of the entire engineering process, including a comprehensive assessment of the life cycle cost.”

It is not a lack of rainfall that leaves Singapore facing water scarcity, rather the challenge of storing rainwater within its 700 km² territory. Decades ago, this led the Government to outline water security plans to ensure sufficient clean water for the nation’s needs.

Today, Singapore’s efficient water supply and wastewater management practices, including the NEWater system for treating used water safely and sustainably, are recognized as exemplary worldwide. The country’s success in water resource management is attributed to new policies, significant infrastructure investments and the adoption of advanced technologies – which now includes the combined Alfa Laval RDTs and centrifuges solution – to enhance availability, improve quality, and reduce costs.

Alfa Laval’s decanter technology is now renowned for achieving optimal cake dryness and for reducing the footprint by delivering energy savings of up to 20% due to the integration of power tubes.

However, Ray Tan and the Alfa Laval team are not resting on their laurels and see more opportunities ahead.

The plant in Kranji is in the process of expanding to increase its treatment capacity of water for further reclamation, and we are working closely together as the relationship with the water agency PUB has become stronger thanks to our constant support and optimization of the machines,” he says. “We did not run away after the commissioning, and this makes Singapore consider us a reliable partner.”

Highlighted Technologies

Water

The KWRP treats 350,000 m³ of water per day

Energy

20 times less energy than old centrifuges

Life cycle cost

CAPEX and OPEX cost optimization - 3 times lower than alternatives