Evaporation solution underpins sustainable production for food ingredients producer

A strategic focus on how sustainability and circularity can be incorporated into production processes is becoming the norm around the world for food and beverage producers keen to align with the expectations of health-conscious and environmentally savvy consumers in a highly competitive market.

DATE 2024-11-18

In Denmark, one such company is an ingredients company that produces organic and conventional products chiefly from fruits and berries. These include juices, concentrates, purees, food supplements, ready-to-drink products, and health shots.

The company sources predominantly home-grown raw materials, with some grown and transported for processing from other parts of Europe.

The company produces ingredients directly from farmers and farms and with a focus on organic raw materials and also conventional Danish-grown raw materials where their considerations for a minimal effect on the environment was factored in.

This environmental focus in the company’s production methods means that equipment and technology have been specifically selected to ensure that energy efficiency and water use are optimized.

They have been assisted on their sustainability journey by Alfa Laval, whose equipment and process expertise in evaporation systems have facilitated the generation of 6.8 tonnes per hour of 54°C condensate water, which is reused in upstream and downstream processes, including CIP and cooling water.

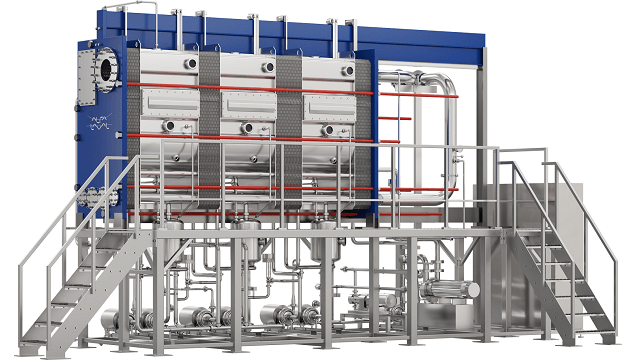

The evaporation system in operation is an AlfaVap Inline. This multiple-effect plate evaporator was the ideal solution for concentrating the many different high-value juices that the company produces.

“The AlfaVap Inline is second to none in the world right now,” says Duojian Xie, Senior Project Manager, Evaporation, for Alfa Laval, who oversaw project execution including engineering, installation, commissioning and service of the new system at the Sorø plant. “It is a very compact space-saving unit using less steel and with a relatively small footprint, which was important at this site in Denmark where space is at a premium. It also reduces retention time to minutes - minimizing product exposure to heat by up to five times compared to falling film evaporators, resulting in higher product quality.”

Despite its small size, it has a large capacity while being plug & play, meaning that the on-site installation of this maintenance-friendly technology took just a week, ensuring minimal interruption to production schedules.

“Our module delivers efficient, large-capacity evaporation with a small skid footprint, and this one piece of equipment is suitable for many different applications,” says Duojian. “The company produces many types of juices from various recipes. Our model is compatible and adaptable to their varying requirements and multiple processing lines. The generation of 6.8 tonnes/hour of condensate and the opportunity to reuse this water was the icing on the cake from a sustainability perspective.”

Highlighted technologies

Water: 6.8 tonnes per hour of 54°C condensate water, which is reused in upstream and downstream processes, including CIP and cooling water

Footprint: AlfaVap Inline is a very compact space-saving unit using less steel and with a relatively small footprint