Evaporators raise process flexibility, product quality, and productivity

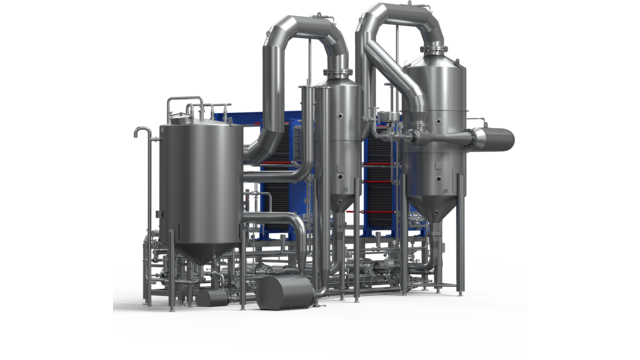

A leading global premium soluble coffee company produces quality 100% Colombian freeze dried coffee for worldwide consumption. To explore more sustainable solutions for its plant, the company teamed up with Alfa Laval for a 4,000 l/h-capacity AlfaVap evaporator to concentrate coffee extract for downstream freeze drying. The result? More compact, economical evaporation systems, energy-efficient separators and decanters, and a long-term partnership, including service and support.

DATE 2025-01-24

Process flexibility and product quality key

The coffee company wanted to improve process efficiency and meet its sustainability goals. To enhance its sustainability credentials, the coffee maker installed a compact, double-effect Alfa Laval plate evaporator. More economical than shell-and-tube evaporators, the plate evaporator extracted the soluble compounds from the fresh, roasted 100% Colombian arabica dissolved in hot water yet retained the coffee’s intensity and flavour. “The Alfa Laval plate evaporator improved the production process at our plant and delivered great results – exceptional coffee taste and aroma,” says the project manager in charge of factory development. “It easily integrated with our plant’s control systems, making operation and maintenance easy.”

Our business relies on Alfa Laval. So do coffee aficionados the world over.

Coffee company project manager for factory development

33% lower installation costs than shell-and-tubes

About one-third the height of shell-and-tube evaporators, the Alfa Laval evaporation system cut installation costs by 33%. Unlike shell-and-tubes, no costly, time-consuming, last-minute welding is required. Fully assembled and factory tested, to the Alfa Laval evaporators ensure trouble-free assembly on site. Its reduced size means low hold-up volumes, which increase the evaporation rate and enhance product quality.

Energy-efficient, space-saving concentration

To prevent any loss of product quality due to thermal impact, the Alfa Laval evaporator removes water from the coffee under vacuum conditions at very low temperatures (below 66°C or 150.8°F). Its compact size minimizes energy losses when transporting the coffee through the evaporator and thermal losses due to shorter exposure to heat transfer surfaces

Large evaporator increases capacity, pilot unit tests new products

Success with this evaporator prompted the coffee producer to invest in a 10,000 l/h-capacity Alfa Laval plate evaporator as well as a 200 kg/h pilot unit for product development.

Glocal support and service – and sustainable optimization

Fast response to the company’s requests for support and service comes from local Alfa Laval service engineers and the nearby service centre as well as through remote assistance from Alfa Laval’s evaporation experts in Denmark and Italy.