Pure fibre goodness with tailor-made membrane systems

Dietary fibre is essential to good gut health, while in reality, it is sub-optimal in the diets of 90% of people living in North America. Meliora Bio, a Denmark-based company focusing on innovative food ingredients and second-generation bioethanol, seeks to change this with its partner COMET. COMET manufactures a high-quality soluble prebiotic fibre branded as Arrabina, which is produced from upcycled crops using renewable energy.

DATE 2025-05-19

Arrabina can be used in a wide array of food and beverage applications, including tea, coffee, carbonated beverages, protein powders, baked goods, snacks, chocolate and confectionery.

“Using sustainable food sources including straw, leaves and shells, our patented production process upcycles crop leftovers and turns them into high-quality ingredients,” explains a spokesperson for Meliora Bio. “We ensure high product quality by partnering with farmers and food companies to source organic and non-GMO leftovers. These partnerships benefit farmers and food companies by allowing them to profit from the entire harvest and reduce waste.”

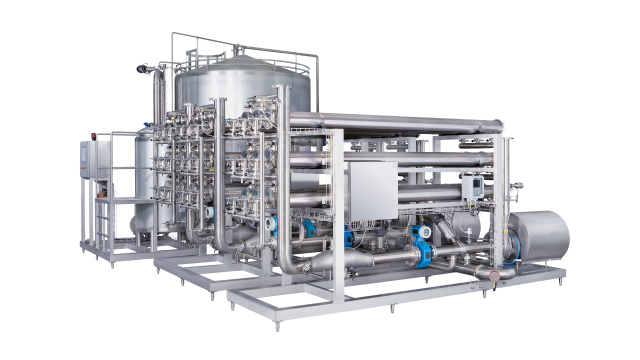

At COMET’s production plant in Denmark, Alfa Laval’s membrane technology plays a central role in the extraction process, which uses steam, water and pressure in a low-impact solution based on sustainable manufacturing – utilizing biomass combined heat and power (CHP) for steam, wind energy for power, and with low water use.

The first-of-its-kind facility in Kalundborg was first upgraded in 2021. Alfa Laval has provided the bespoke and world-leading membrane filtration system at the plant, which was developed at Alfa Laval’s membrane filtration knowledge centre in Nakskov and produces purified fibre of such high quality that it can be used in both solid and liquid form, bringing added sustainability benefits in the reduction of waste in the process.

“When the crop residues enter the plant, the dietary fiber is extracted and isolated into a liquid,” says Jesper Engsig, Market Area Manager in Alfa Laval's Food & Water Division. “The liquid is then converted into a fully-soluble powder that can easily be added to foods and beverages.

“But because the filtration is of such a high quality, it has turned out that the liquid fibres can actually also be used, and thus all raw material can be utilized so that nothing goes to waste, which is very positive!”

It’s another sustainability benefit for the facility, which, together with its renewable energy source, makes it possible to produce prebiotic dietary fibre with very low CO2 consumption. While the solid fibres go on to be added to foods such as breakfast cereals, muesli bars and pastries, the liquid ones can supplement the fibre content of products like juices and soft drinks.

Alfa Laval has also delivered a monitoring system to the facility to ensure the filtration process is continually monitored and reviewed.

“We are very pleased to build the specially developed production facility with equipment from Alfa Laval,” says the spokesperson for Meliora Bio. “The new equipment enables us to meet our customers' needs for prebiotic dietary fibre, which is soluble and easy to add to nutritional bars, baked goods, beverages, and other products that consumers demand to support a healthy and well-functioning gut microbiome.”

Around 4,000 tonnes of dietary fibre will be produced per year at the plant in Denmark, and the company is now part of Kalundborg Symbiosis, the world's leading industrial symbiosis, where 16 public and private companies are part of a partnership that is based on a circular approach to production.

Highlighted technologies

Sustainable food produced from by-products contributes towards producing more food to meet the need for up to 70 percent more food by 2050 (UN, 2019)

A third of all food goes to waste in the food chain between farm and fork (UN, 2019). The upcycling of by-products contributes towards the reduction of food waste.