Sustainability boost from Aldox upgrade with heat exchanger uplift

Another milestone in successful Romanian synergy. When it comes to meeting ambitious sustainability targets, one brewer in Romania is seeing striking results from its latest operational upgrade – and is also enjoying the significant benefits of its long-term relationship with an expert industry partner that goes way beyond equipment provision.

DATE 2025-04-23

Ursus Breweries is looking to be carbon neutral in its operations by 2030, and in an industry that uses – and heats and cools – a lot of water, that target offers major challenges.

But working with Alfa Laval means that they are taking major steps forward towards the milestone, and the latest upgrades to its Aldox technology, which produces deaerated water, have delivered a major sustainability boost, and is the latest highlight in a productive relationship that has thrived over two decades.

Valeriu Radu, Technical Sustainable Development Manager for Ursus Breweries, explains: “We started working with Alfa Laval in Romania in 2004, and have been co-operating together successfully ever since. We are very satisfied with the quality of the Alfa Laval products, but it is not only that.

We prefer to work with companies that are providing more than just equipment. Companies which are providing also the knowhow so that we can have a partnership with these companies, because in the end we are looking for partners, not just suppliers, and we count on their technical experience to support us in order to optimize our processes.

Valeriu Radu

Technical Sustainable Development Manager, Ursus Breweries

When it comes to that drive for sustainability, partnership working is more important than ever and Alfa Laval has aligned its expertise with the goals of Ursus, who are a subsidiary of Asahi Breweries Europe Ltd, employing around 1,400 people in Romania and operating three breweries in Timișoara, Buzău and Brașov as well as a craft mini-brewery in Cluj-Napoca.

It is at the Brașov brewery, with a history that goes back to 1892 and a proud reputation for employing the latest technologies and ideas, that Ursus has recently worked with the Alfa Laval team to identify efficiencies to boost profitability and enhance the sustainability of their operations. A key action from this is the upgrading of the brewery’s Aldox unit to deliver greater energy savings and thermal efficiency, as it drives the production of 1.2 million hectolitres of beer every year.

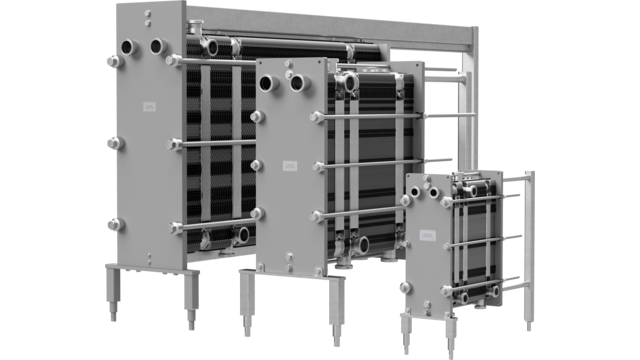

The unit, which deaerates and pasteurizes incoming water, was originally bought by Ursus in 2005. It included a regenerating heat exchange section with around 90-92% efficiency, which has now been boosted to a minimum of 95% thanks to the Alfa Laval upgrade.

Head of Regional Sales, Global Sales, Brewery Systems at Alfa Laval, Antoniu (Toni) Stefan, explains further: “The regen section is where we recover energy as the incoming water is heated regeneratively by the outgoing water. By enhancing the regen section to 95% efficiency with the newly launched HL8 heat exchanger, we need less energy for the pasteurization process, and we need less steam to heat up the water and less glycol for cooling.”

The new HL8 heat exchanger provides a saving in heating that equates to 58 kilowatts, and in cooling to 59 kilowatts, and this means that, with the Aldox module, for every 200 hectolitres of deaerated water produced, Ursus saves about 16,300 euros per year.

The Ursus team know that the upgrade will deliver benefits as they have already gone through the same exercise at Timișoara and Buzău as they respond to a group-wide initiative to ensure that all of the regen sections in their heat exchangers across the world operate to a minimum of 95%.

Valeriu says: “We want to optimize everywhere we can, to recycle the heat as much as possible. This is one of the examples but we want more and I am working with Toni to discuss another application to optimize our thermal usage in the brewhouse. We are seeking out these kinds of projects and we are really active in these kinds of areas to reduce our overall gas consumption.”

Antoniu adds: “It is great when you have a customer like Valeriu who knows exactly what to ask and where to look, and understands what we are talking about. There is an excellent synergy between our organizations where we both benefit: we help them upgrade existing equipment and help them operate better, smarter, cheaper and more sustainably, and we learn so much from them and their experience. I probably owe him a beer!”

Highlighted technologies

Energy savings: 315,900kWh/year

CO2e savings: 94,500 kg