Plate heat exchangers are designed to optimize heat transfer because the corrugated plates provide by far the greatest surface area through which the heat can be drawn from one gas or liquid to the other. Despite this substantial area for heat transfer, plate heat exchangers are usually relatively compact. The design of the plate channels also ensures maximum turbulence as each fluid passes through. This results in maximum efficiency in transferring heat from one medium to the other.

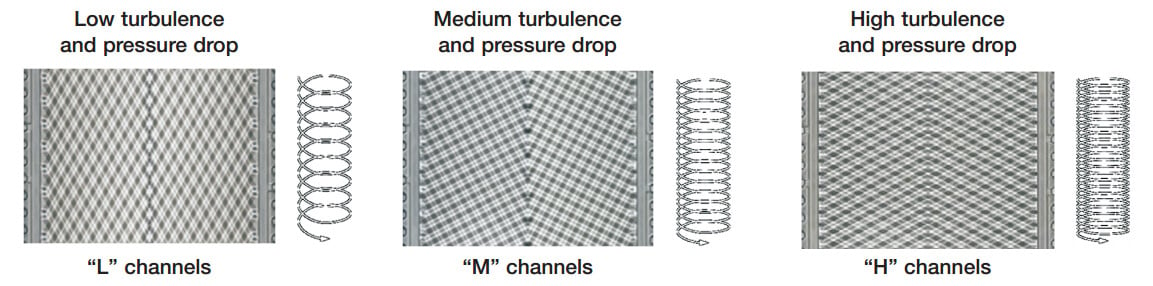

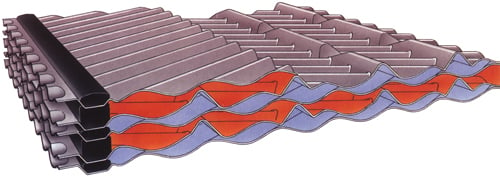

The heat exchanger plates are pressed in a so-called herringbone corrugation pattern. When two plates are superimposed with opposing herringbone patterns, this type of corrugation generates a helix-like flow with very high turbulence, thus producing the essential condition for achieving high transfer coefficients and effective heat exchanger self-cleaning. By changing the plate corrugation pattern, the heat exchanger can be used in different processes, even those with very dirty media.

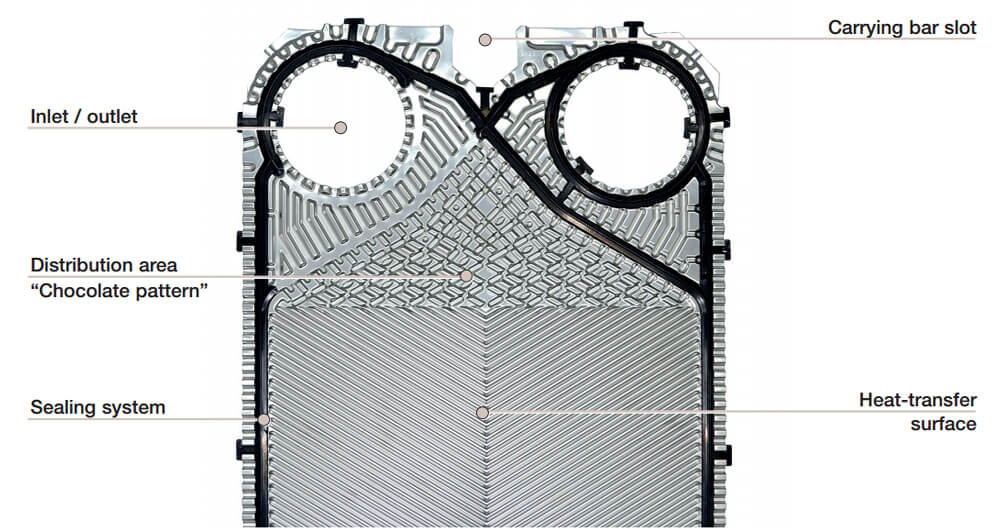

The plate distribution is pressed in a chocolate pattern (an Alfa Laval design feature). This type of corrugation has numerous advantages:

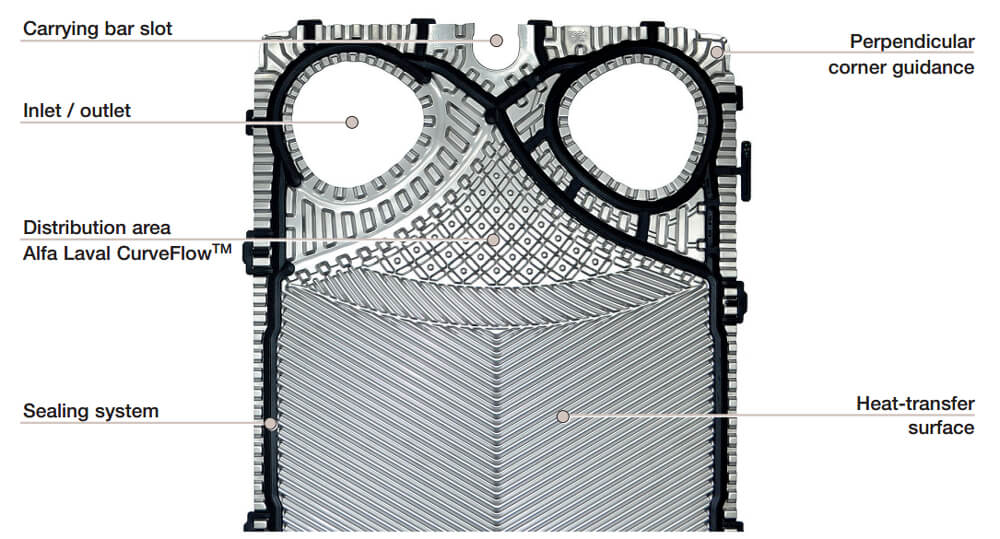

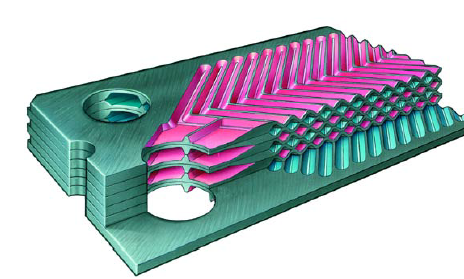

The new design of the CurveFlow distribution area means superior flow distribution and more of the available pressure drop over the main heat transfer area. This results in a number of benefits:

With the new CurveFlow design the media is more optimally distributed over the entire plate width. Additionally, the cross corrugation pattern between the distribution surface and the main heat transfer area gives improved heat transfer. Compared to a traditional plate design, it's also possible to use thinner plates at high pressures. Total improvement of the heat transfer efficiency is up to 15%.

Thanks to the non-circular ports, the port area in the plate has increased compared to a conventional circular design. This equals to higher flow capacity at the same velocity, allowing higher utilization.

The media will have up to 20% higher velocity at the far end of the plate width. This will improve the shear stress over the heat transfer area by up to 40%, minimizing the risk of fouling build-up at the most critical part of the plate.

The new corner guiding design ensures that the plate pack is perfectly aligned independent of the number of plates. A perfect alignment ensures a reliable performance of the heat exchanger and faster closing of the unit after service.

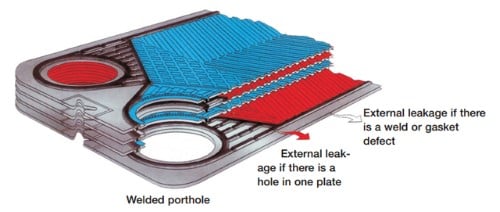

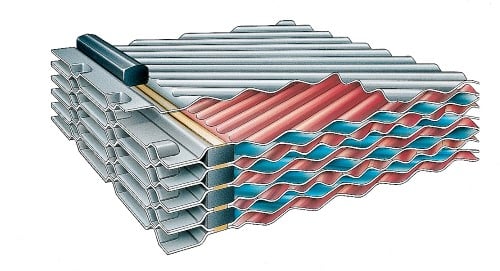

Double-wall gasketed plate heat exchangers are ideal for use with fluids that must not be allowed to mix. Pairs of identical plates are laser-welded around the ports. The gasket is installed in the conventional manner and the welded plate pairs are assembled in a plate pack in the same way as ordinary single plates. In the unlikely event of leakage through a plate because of a puncture or crack, the leaking fluid will never come into contact with the fluid in the other circuit, as it will be stopped by the double plate and flow outside the heat exchanger.

With wide channels free of contact points, this plate is ideal for fluids containing fibers or coarse particles. Each channel is designed to eliminate bridging of solids in the entrance area.

With wide channels free of contact points, this plate is ideal for fluids containing fibers or coarse particles. Each channel is designed to eliminate bridging of solids in the entrance area.

Learn more about WideGap plate heat exchangers

Welded channels for process fluids allow aggressive and difficult fluids to be

handled in a plate heat exchanger and expands the pressure range. The

gasket exposure is minimal on the welded side.

Learn more about Semi-welded plate heat exchangers

A composite of fused graphite and fluoroplastic, Diabon plates provide excellent resistance to hydrochloric acid and other corrosive materials. Unlike traditional graphite, Diabon F has no porosity or permeability. It resists cracking and breaking during handling and use.

Learn more about Diabon plate heat exchangers

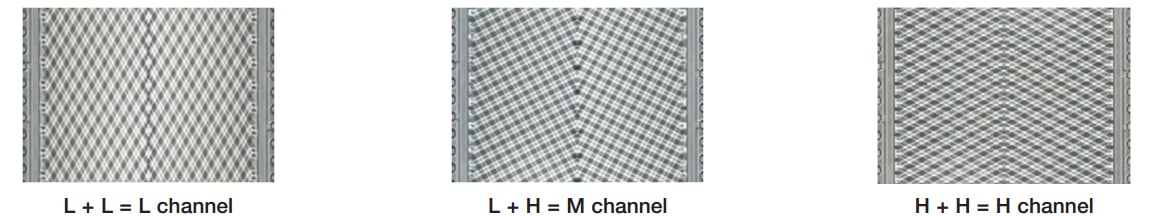

Your optimal channel type is selected on the basis of the temperature program to be satisfied and the maximum permissible pressure drop.