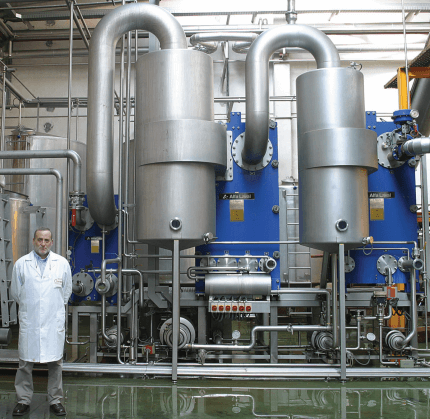

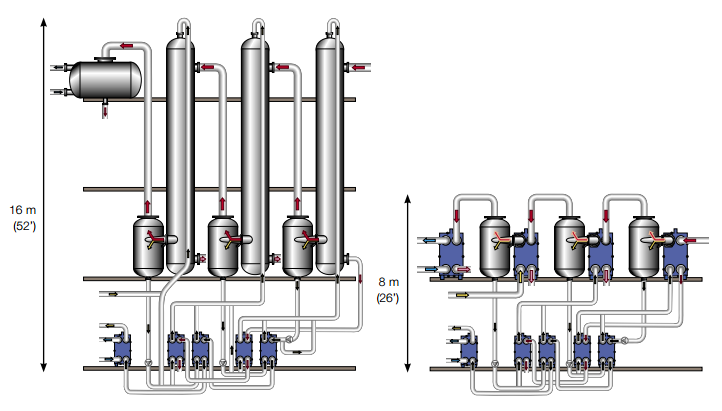

AlfaCond condensers are specifically designed for condensing of vapor under vacuum. The compact design is easy to install where space is crucial.

AlfaCond is an alternative to direct condensers when condensate recovery is the goal and when there are space constraints. The AlfaCond can be configured with or without subcooling of the condensate. Non-condensables are removed from the condensate outlet pipe and led to the vacuum system.

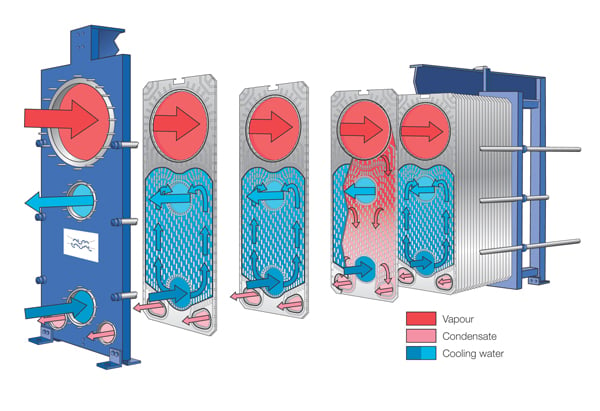

The heat transfer area of a gasketed plate-and-frame heat exchanger consists of a series of corrugated plates, assembled between the frame and pressure plates, which retain the design pressure. The sealing between the plates on the AlfaCond alternates between laser welds and gaskets. It has a unique porthole configuration that is specifically designed for vacuum condensation. Vapor condenses in the welded channel and the cooling water passes through the gasketed channel.

The heat transfer area of a gasketed plate-and-frame heat exchanger consists of a series of corrugated plates, assembled between the frame and pressure plates, which retain the design pressure. The sealing between the plates on the AlfaCond alternates between laser welds and gaskets. It has a unique porthole configuration that is specifically designed for vacuum condensation. Vapor condenses in the welded channel and the cooling water passes through the gasketed channel.

The channel gap size is asymmetric with a larger gap on the vapor side and a smaller gap on the cooling water side. The result is a very low pressure drop on the vapor side and high velocity and turbulence on the cooling water side. Together, these maximize heat transfer efficiency and minimize fouling.

It's important to understand that all gasketed plate heat exchangers are not the same. The features highlighted below are important components to look for in a GPHE, and when combined, these features offer extensive benefits, such as reduced total cost of ownership, higher efficiency and increased staff safety.

Glue between the gasket and the metal plate safeguards high quality bonding for the toughest operating and service conditions. A two-component oven-cured epoxy glue, that can only be removed from the plates by special treatment, will keep the gasket on the plate during cleaning.

Gaskets attached to a plate with rubber glue, oven-cured or not, does not achieve a strong enough bond, which can result in gaskets falling off during cleaning, when the temperature gets critical or when aggressive fluids make the gaskets swell.

A device between the tightening bolt head and the frame that reduces friction forces and makes service easier.

Opening and closing the PHE without bearing boxes is time consuming and increases the risk of paint damage, which can lead to corrosion damage.

The pressure plate must be easy to move and slide along the carrying bar in order to gain access to the plate pack. The most common solution is a roller on top of the carrying bar, making it easy and less time consuming to conduct service. The roller should be made out of metal to be able to carry the weight of the pressure plate.

The mechanical solution of the roller can be more or less robust. The risk is a pressure plate that is jammed and impossible to move when it is time to conduct service.

Keeps the plates aligned during closing of the plate heat exchanger that facilitates service.

Many alignment systems do not close the vertical gap between the carrying bar and the plate, leading to wavy plate packs with leaking problems.

Plate heat exchangers have an essential role in most applications. If they function poorly, they may lead to lower product quality, reduced safety and higher energy costs. And if they fail, they can lead to costly downtime and major losses in production. This makes it important to perform maintenance – and important to do it correctly.