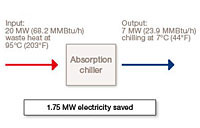

Absorption chilling is a technology that converts low-temperature waste heat to chiller capacity. Absorption chillers are attractive investments in plants with high chilling needs and large amounts of available low-grade heat. Especially if electricity prices are high, since the power consumption of an absorption chiller is practically negligible compared to that of a conventional chiller.

Absorption chillers provide cooling by using heat instead of a compressor. A mixture of ammonia and water is one of two common cooling media (the other one being a mix of lithium bromide and water). The following shows the working principle of an absorption chiller using this refrigerant:

The efficiency of absorption chillers depends on the temperature of the waste heat and the cooling water; the larger the temperature difference the better the efficiency.

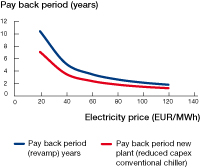

In 2008, Alfa Laval supervised a thesis from Lund University studying waste-heat powered absorption chilling. Assuming there is a high need for chiller capacity and good supply of low-temperature waste heat, absorption chillers proved to be a profitable investment, both when replacing existing chillers and in new plants.

All graphs are based on the master’s thesis: “Evaluation of different alternatives for recovering waste heat from the sulphuric acid process”, D. Iwarsson (2008), Master’s Thesis, department of chemical engineering,

Lund University.