Steenkoolveredeling

Alfa Laval’s range of equipment and proven expertise help optimize key processes in coal beneficiation and add further security to the storage of mine waste. With our solid-bowl decanter centrifuges installed, you can look forward to recovering and re-using large quantities of process water, which will help cut lifecycle cost, minimize environmental impact, save space and boost capacity as well.

Robust technology for coal tailings dewatering

- Excellent output (solids dryness) even in tough conditions

- Removes need for tailings dams

- Reduces footprint as well as capital and maintenance costs

- Contained process resulting in good and safe working conditions

- Full support from our global sales & service team, even in remote locations

Tackling tailings safely and sustainably

Alfa Laval decanter centrifuges are a proven, efficient solution for large-scale dewatering of tailings and removing the finest particles that conventional solids control equipment is unable to deal with. They offer a cost effective, sustainable and, above all, safe solution to manage tailings, acting as a complement to traditional separation systems such as thickeners, sedimentation basins and filters or replacing old systems altogether.

How the technology works

Alfa Laval P2 and P3 decanter centrifuges are specifically designed to separate mineral ore slurries as well as tailings into solid phase and liquid phase. Separation takes place in a horizontal cylindrical bowl equipped with a screw conveyor. The feed slurry enters into the bowl through a stationary inlet tube and is then smoothly accelerated in the feed zone. Centrifugal forces of up to 3,500 G separate the solid particles from the liquid and the solids accumulate on the inner surface of the bowl.

The conveyor rotates in the same direction as the bowl, but at a different speed. This gives an axial thrust to the solid particles and the conveyor conveys those particles towards the conical end of the bowl. The solids leave the bowl through the solids discharge openings into the casing whereas the clarified liquid leaves the bowl by flowing over adjustable plate dams or power tubes into the casing.

Decanter benefits

- Short payback time

- High cake dryness

- High volume capacity

- Contained process resulting in good working conditions

- Full support from our global service team, even in remote locations

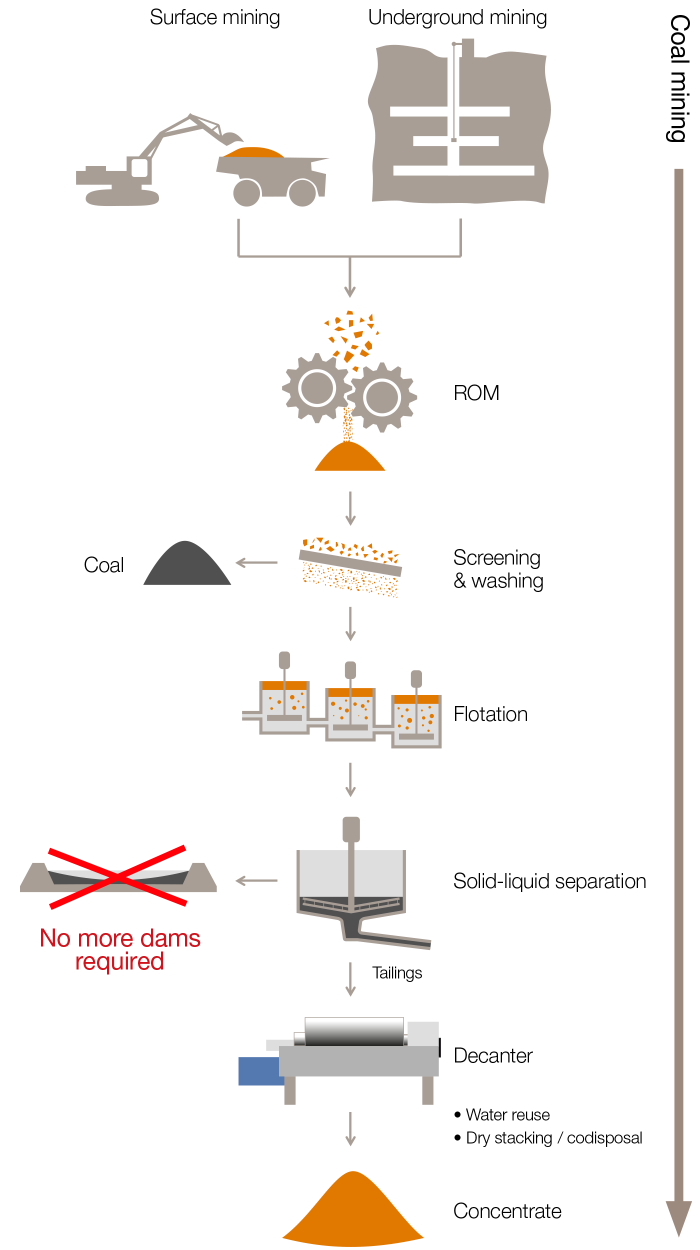

Opportunities throughout your process

Explore the mining flowchart and discover how an Alfa Laval decanter centrifuge can help streamline your operations in various process areas.

Tailing dewatering - Breaking new ground in mining and minerals

Alfa Laval decanters revolutionize coal mine tailings management strategy.

The Rix’s Creek coal mining operation, part of the Bloomfield Group, set out to improve its onsite coal tailings management as part of its sustainability strategy to reduce water and energy consumption and minimize the surface footprint of waste handling processes.

After evaluating various technologies, Rix’s Creek engineers installed an Alfa Laval decanter centrifuge to dry coal tailings.

The result? Savings in capital expenditures as well as, about 90% recovery and re-use of the process water.

Learn more

Read more about the efficiency, practicality and technical details of the Alfa Laval range of solid-bowl decanter centrifuges for the coal mining industry by downloading the brochure.

Tailings management

Meet the tailings dewatering challenge with Alfa Laval’s decanter centrifuges. They offer a cost effective, sustainable and, above all, safe solution to manage tailings. Download the brochure to read more about our cleaner, more efficient and safer solid-liquid separation systems.

Make sustainable development happen!

If you are looking for ways to increase the efficiency of your coal tailings management and make a meaningful contribution to the global sustainable development goals, contact Alfa Laval today to learn more about our proven and cost efficient solutions.