Olive Oil Booster

The Olive Oil Booster system, when integrated into an olive mill, enhances decanter performance. When combined with the olive crusher and vertical centrifuge, it results in significantly higher olive oil extraction quantities and increased antioxidant components compared to conventional olive oil technology. This innovative solution not only boosts oil yield but also improves sustainability by reducing water consumption and operational costs.

Achieve optimal olive oil yield and quality for the entire harvest season

- Maximizes oil yield throughout the entire harvest season thanks to innovative technology combined with efficient processes

- Enhances oil quality by increasing phenol extraction. This means healthier, longer lasting oil with a higher retail value

- Improves sustainability with lower water consumption together with a higher process capacity

- Significantly increases the amount of “free oil” released, which improves paste preparation and, in turn, decanter centrifuge performance

- Boosts oil mill profit margins through higher yields, higher oil quality and reduced impact on operational costs

Olive Oil Booster is capable of reducing the consumption of the process water and by consequence the water disposal, with reduction of cost and environmental risk. Due to the increase of extraction rate per Kg of olives, Olive Oil Booster system is efficient also from energy consumption point of view.

The Olive Oil Booster system is a combination of different technologies working together to maximize oil yield and quality in oily fruit processing. The Olive Oil Booster into an olive mill improves decanter performances and, in synergies with olive crusher and vertical centrifuge, allows to extract significantly higher quantity of olive oil together with higher quantity of antioxidant components.

The Olive Oil Booster technology allows to increase income results without increasing the operating cost. Making easier the oil extraction from fruit pulp, Olive Oil Booster is capable to reduce the consumption of the process water and by consequence the water disposal, with reduction of cost and environmental risk.

Reap the benefits of the Olive Oil Booster

Producing high quality olive oil as cost-efficiently as possible is top of the agenda in many olive oil mills while making the quality of their products stand out. Watch this video and get a glimpse of this cutting-edge solution that leads to a significantly higher quantity of "free oil" with a significantly higher quantity of phenols in the extracted olive oil.

The Sacco Oliveti case story

For Italian olive oil producer, Sacco Oliveti quality is paramount. The family-owned company has been producing extra virgin olive oil for decades from the distinctive Peranzana olives, grown across 6,500 hectares of ancient olive groves in Puglia.

Documents

Download the white paper to find out how to maximize oil yield and quality

How does the Olive oil Booster help maximize olive oil yield while improving oil quality

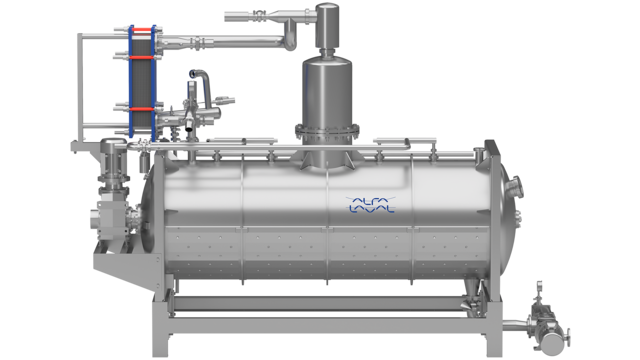

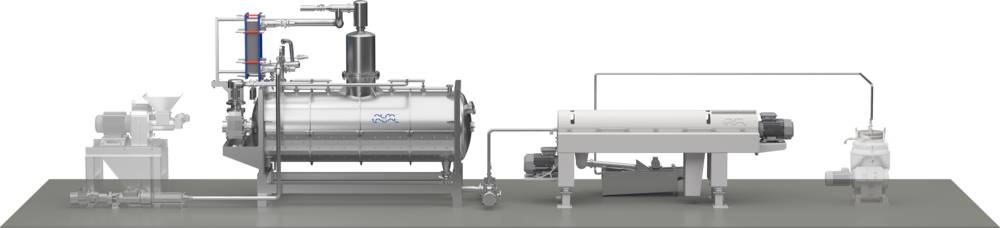

Alfa Laval Olive Oil Booster system works with a combination of thermal and separation solutions, with Plate Heat Exchanger (PHE) and Decanter centrifuge as core technologies. This is what makes Alfa Laval Olive Oil Booster system a class-leading technology, while maintaining the traditional process flow, as can be seen following it step by step:

Step 1 – Crushed olives are transferred into the booster

As seen in traditional oil mills, olives are crushed, and the resulting olive paste is promptly transferred into the Booster under a specified vacuum pressure. The vacuum pressure facilitates rapid cooling and the removal of oxygen, as the temperature of the olive paste after crushing exceeds the boiling point of water.

Step 2 – Booster release of “oil free” from the olive paste

Olive paste is agitated by the horizontal shaft with blades for a certain time at a settled pressure (deep vacuum) and temperature. Keeping the vacuum pressure below the boiling pressure at a settled temperature (i.e. 18°), olive paste is kept under boiling condition where a certain amount of water change physical phase from liquid to vapor.

The boiling at cold condition of olive paste is capable to produce bigger oil drop and higher amount of “free oil” rich in phenols compared to the traditional malaxing, with a consequent significative increase of oil yield of higher quality. The energy necessary for this physical phase change is given by hot water circulating into the jacket of vacuum tank heating the olive paste. The little quantity of vapor produced during exposition of olive paste to the vacuum is condensed by a plate heat exchanger with cold water produced by a chiller and the little quantity of condensate vapor is returned to the extraction process. Because the paste is boiling at low temperature, there is not negative effect on the amount of positive aroma compounds of olive oil. On the contrary, some negative aroma compounds with light molecular weight such as ethanol, acetic acid and ethyl acetate can be removed from the oil by the Olive Oil Booster technology.

This step of “free oil” release could be obtained entirely by Olive Oil Booster, or by using the Booster in combination with traditional malaxing.

Step 3. Separate the oil with a decanter centrifuge

The Olive paste prepared by the Olive Oil Booster is fed into the Decanter centrifuge where the oil is separated from water and solids, working in two or three phases. Performance of Decanter in terms of capacity, oil clarity, residual oil in the husk and quantity of dilution water (in case of three phases), is strictly depending on the characteristics of the olive paste prepared during the previous operation.

With traditional malaxation system, the results on “free oil” production and oil drop dimension are strictly depending on many variables such as fruit ripeness, fruit moisture, fruit variety, crushing technology, etc. The paste preparation made by the Olive Oil Booster is globally improved in terms of oil drop dimensions and production of “free oil” with respect to traditional method. This improvement is obtained independently from fruit characteristics when compared with traditional method.

All this is traduced in a significant improvement of performance of the separation in the Decanter with clear advantages in the reduction of the residual oil in the husk, increase of throughput capacity, improve of oil clarity and reduction of dilution water quantity when used. Improved oil clarity obtained by the Decanter after the Olive Oil Booster is also an advantage for the improved performance of vertical centrifuge for oil purification. An oil coming from Decanter with less impurities improves the vertical centrifuge capacity and reduces number of the cleaning stops.

Service

De prestaties van uw apparatuur verbeteren

Ons toegewijde wereldwijde servicenetwerk ondersteunt u met onderdelen en deskundigheid, waar u ook bent en wanneer u het ook nodig hebt. Door te zorgen voor meer uptime, beschikbaarheid en optimalisatie, bieden we u gemoedsrust en helpen we u het rendement op uw investering te maximaliseren. We kunnen met u samenwerken om onze services te integreren in een Alfa Laval Service Agreement voor een voorspelbare en onbezorgde bedrijfsvoering.

Neem voor vragen contact met ons op.