SolidC

The Alfa Laval SolidC is a standardized centrifugal pump for the basic transport of process fluids in hygienic applications. Its hygienic design, cost-effective operation and quick, easy maintenance offer excellent value for money.

Solid value for money – consistent performance, excellent hygiene and maximum cleanability

- Low process contamination risk – compliance with global hygienic design standards and verified cleanability

- More uptime due to quick and easy maintenance

- Continuous operation – no unplanned production stops due to robust mechanical design and front-loading shaft seal

- Peace of mind thanks to an extended three-year warranty

The SolidC is a reliable, cost-effective centrifugal pump that delivers consistent performance in hygienic applications.

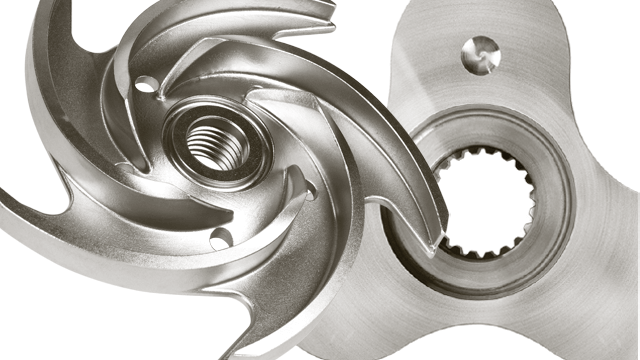

Its semi-open impeller, external front-loading shaft seal, single-piece stainless steel housing, and long-life compression couplings contribute to solid performance, high product quality, and ease of maintenance.

This standard centrifugal pump is available in four models capable of handling flow rates up to 80 m3/h, pressures up to 8 bar at 50 Hz, and inlet pressures up to 4 bar.

Close at Hand catalogue

The hygienic equipment product catalogue "Close at hand" includes product leaflets, links to animations, brochures and lists for ordering purposes.

CAD portal

The Alfa Laval CAD portal is an essential platform for downloading detailed product information, 2D drawings and 3D product models.

Solid hygienic design

Minimize contamination risks through compliance with 3-A Sanitary Standards, CE, FDA and EHEDG requirements.

Gentle product handling

The semi-open impeller of the SolidC ensures gentle product handling and high product integrity.

Easy, low-cost maintenance

With the spring and washers mounted on the atmospheric side, the front-loading shaft seal ensures quick, easy and cost-effective

SolidC pumps use the same external mechanical shaft seal as the Alfa Laval LKH premium range of centrifugal pumps. This reduces spare parts inventory for plants that use both standard and premium Alfa Laval centrifugal pumps.

Product Benefits

- Hygienic design

- Cost-effective operation

- Quick and easy maintenance

Alfa Laval LKH Prime

Premium goes Prime - Setting a new standard in self-priming pump technology.

Alfa Laval LKH Prime

Service

Our dedicated Global Service Network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment. We can work with you to integrate our services into an Alfa Laval Service Agreement for predictable and worry-free operations.

Learn more about our service offer Troubleshooting

Serial number search Certification

Please contact us with any queries or questions.

How it works

Operating principle

The pump impeller of the Alfa Laval SolidC centrifugal pump is mounted on a shaft, driven by an electric motor. The shaft turns and transfers the rotational energy to the fluid passing through the pump. The centrifugal force of the fluid increases the fluid’s kinetic energy and velocity as well as the pressure in the pump. The centrifugal force then directs the fluid towards the pump outlet.

Pump range

Four different SolidC models handle flow rates up to 80 m3/h, pressures up to 8 bar at 50 Hz, and inlet pressures up to 4 bar.

Unique impeller design

The semi-open impeller with a unique multi-vane design ensures particularly low NPSHr (Net Positive Suction Head required), which helps prevent cavitation and minimizes the risk of mechanical damage. Impeller balancing holes enhance circulation around the shaft seal and reduce axial forces. This maximizes cleanability and minimizes wear on the shaft seal and motor bearings.

One-piece pump housing

The pump housing is constructed from a sturdy, single piece of stainless steel. There is no need to disconnect or remove the pump casing from the process line during inspection or maintenance. This feature, combined with a front-loading seal, minimizes downtime and saves time and money.

Optimized shaft seal

One shaft seal fits all models of SolidC and LKH pumps. This standardization reduces inventory and makes wear parts replacement quick and easy.

Compression coupling

The compression coupling attaches the stub shaft to the motor shaft with precision alignment. Setup is simple, operations secure and noise, vibration minimized, and the service life of the shaft seal and motor prolonged.

You might also be interested in...

Part of a broad pump range

Alfa Laval offers a comprehensive range of pumps intended for hygienic applications in the dairy, food, beverage, home care and personal care.

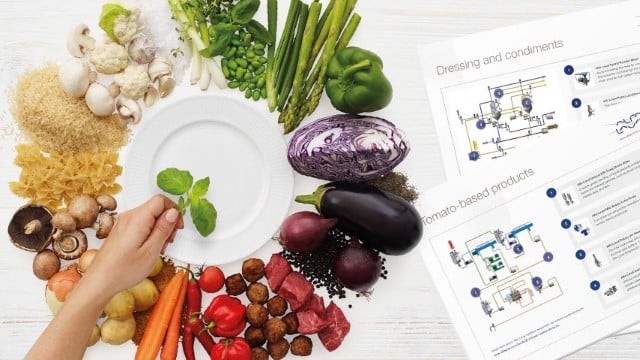

Food Logic

Alfa Laval's hygienic equipment combines high performance with gentle handling to preserve sensitive ingredients and keep up with the food industry trends. The equipment addresses four key challenges; supplying food products to consumers at a competitive price, getting the most from raw materials, reducing waste and emissions, and delivering safe and hygienic food products.

Subscribe near Newsletter

Stay updated on important sustainability issues and opportunities in your industry and processes!

Animations

Visit the animations site and take a look inside a product to see and understand how it works.