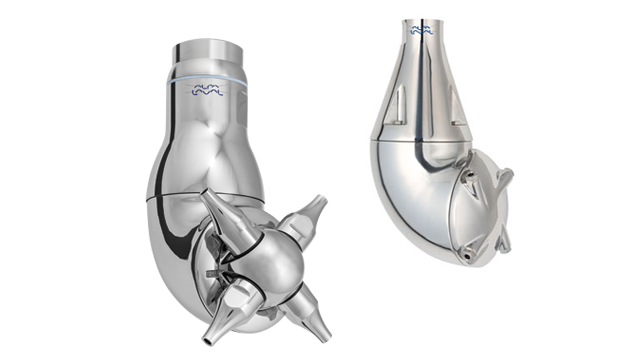

TJ

Alfa Laval’s range of rotary jet head tank-cleaning devices provide exceptional cleanability, better end-product quality, greater overall output and up to 70% reduction in operating costs. They are designed for hygienic applications, such as food, dairy, personal care and beverages.

High impact quality assured tank cleaning in a 360° repeatable cleaning pattern

- Avoid contamination with effective cleaning performance and superior self-cleaning features

- Cost efficient and sustainable solution due to reduced water and chemicals requirements

- More available production time because of reduced cleaning time

- Easy to service and maintain – no special tools required

- Control of CIP through validated cleaning

The TJ range of rotary jet heads provides automated 3D-indexed impact cleaning over a defined time period for processing, storage and transportation tanks and other vessels between 15 and 500 m3. The award-winning design is suitable for cleaning brewing equipment as well as for food and dairy processes and is a cost effective means of achieving hygienically safe, quality assured tank cleaning.

How does the TJ rotary jet head work

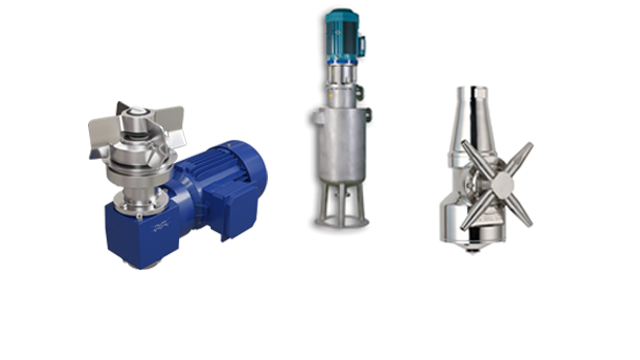

Dynamic tank cleaning machines

The flow of the cleaning fluid makes the nozzles of the rotary cleaner rotate around the vertical and horizontal axes. In the first cycle, the nozzles deposit a coarse pattern on the tank surface. Subsequent cycles gradually add density to the pattern, until full coverage is reached after eight cycles. The operation of our automatic tank cleaning equipment is fully automatic and provides users with effective quality assurance guarantees in tank cleaning, complete with all the necessary documentation.

Complete self-cleaning system

Not only does the Alfa Laval TJ range of rotary jet heads provide spotless cleaning of the tank interior, it also cleans itself – inside and out. The hygienic self-cleaning design ensures that the flow of the cleaning fluid covers the external surfaces of the rotary jet head to reduce the risk of cross contamination and potential product loss or recalls.

1. Overlap ensures self-cleaning of the body

2. The nozzle’s concave shape ensures self-cleaning of the nozzle itself

3. Through two holes in the hub, jet streams ensure cleaning of the cone

Low pressure drop

The low pressure loss over the machine results in increased cleaning efficiency compared with other tank cleaning machines running at the same inlet pressure. This results in lower cleaning costs as the unit can run at lower pressure/flow.

Effective tank cleaning with low operating costs

The strong jet generates a high mechanical force and covers 360° to efficiently remove remaining products and residues and provide the best hygienic conditions for production. As the force generated by the rotary jet head increases, the water consumption decreases, which leads to significant cost savings as illustrated in the diagrams. (based on Dr. Sinner’s cleaning philosophy.

- Cost savings (water, chemicals): 70%*

- Time saving = more production time: 60%*

*compared with traditional static spray ball cleaning

Static Spray Ball

Blue = Water consumption/time

Red = Mechanical action

Alfa Laval TJ20G / TJ40G

Yellow = Temperature

Grey = Chemicals

Close at Hand catalogue

The hygienic equipment product catalogue "Close at hand" includes product leaflets, links to animations, brochures and lists for ordering purposes.

CAD portal

The Alfa Laval CAD portal is an essential platform for downloading detailed product information, 2D drawings and 3D product models.

Q-doc documentation package

Alfa Laval Q-doc is a comprehensive documentation package for our UltraPure equipment, ensuring full traceability of all product contact parts.

Explore the documentation package

Service

Our dedicated Global Service Network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment. We can work with you to integrate our services into an Alfa Laval Service Agreement for predictable and worry-free operations.

Learn more about our service offer Troubleshooting

Serial number search Certification

Please contact us with any queries or questions.

Visit the Application & Innovation Centre

Do you want to identify the optimal equipment for the job and discover tangible savings before deciding on upgrades? In the Alfa Laval Application & Innovation Centre, you can do just that.

Optimize™ by Alfa Laval

Optimize™ by Alfa Laval boosts your existing processes and enables up to 90% savings on water, energy and chemicals with only small and no-risk investments.

Happy Customers

Ten top tips - Tank Equipment

Here are some tips and service videos to show you how you can keep your tank equipment in tip top condition.

Subscribe near Newsletter

Stay updated on important sustainability issues and opportunities in your industry and processes!

Animations

Visit the animations site and take a look inside a product to see and understand how it works.