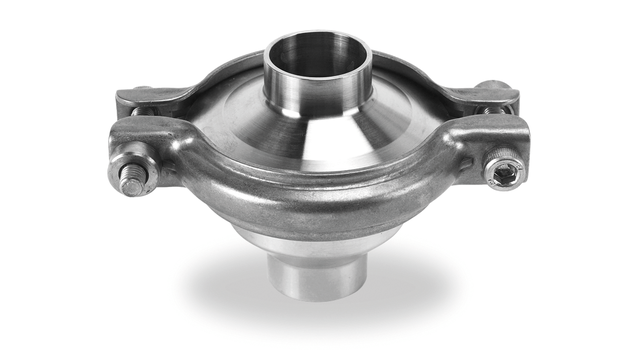

LKC Non-return Valve

The Alfa Laval LKC Non-return Valve is a hygienic one-way check valve for use in various processes across the hygienic industries to prevent reverse flow. It is easy to install, ensuring safety and high product quality. It is available in two versions: the LKC-2 for vertical flow and the LKC-H for horizontal flow

Non-return valve preventing the reverse flow of fluids

- Highly reliable, self-acting valve

- Easy to install

- Protects process equipment

- Prevents reverse flow

The LKC Non-return Valve is widely used for single directional product flow through hygienic process lines across the dairy, food, beverage, brewery and many other industries.

Product catalogue

CAD portal

The Alfa Laval CAD portal is an essential platform for downloading detailed product information, 2D drawings and 3D product models.

Safe and reliable process protection

Alfa Laval LKC-2 Non-return valves are highly reliable check valves ensure single directional product flow through process lines. This provides protection for process equipment that can be affected by reverse flow and prevents pressure surges and/or system shutdown.

Non-return valve range

The standard range of Alfa Laval LKC-2 non-return valves are constructed of standard 304 or acid-resistant 316L stainless steel. Easy to install, the valves are designed to handle maximum product pressure up to 10 bar and temperatures ranging from -10°C to 140°C (EPDM). For added versatility, these check valves are available with either a semi-bright or polished finish, and a variety of welding ends for ISO or DIN connections.

For more information, please refer to Documentation.

Product Benefits

- Highly reliable

- Easy to install

- Protection for process equipment

Find the products you are looking for

The digital Alfa Laval Product Catalogue makes it easy to find and select the products you need. When you request a quote, the catalogue will list Alfa Laval’s partners in your region – and you can send your request directly.

How it works

Construction

The Alfa Laval LKC-2 non-return valve consists of an upper valve body, lower valve body, valve plug, seal ring, and guide disc. The valve body is assembled by means of a clamp and hygienically sealed with a special seal ring. A guide disc and four legs guide the spring-loaded valve plug with an O-ring seal. LKC-2 has welding ends for ISO or DIN connections.

Working principle

The spring acts on the valve plug, keeping the valve closed until the force from the pressure in the inlet exceeds the force of the spring. If a reverse flow should occur, the spring force and the pressure from the outlet will keep the valve closed.

Options

Product wetted seal rings in NBR or FPM.

Part of a broad valve range

Alfa Laval offers a comprehensive range of valves intended for hygienic applications in the dairy, food, beverage,home care, personal care, biotechnology and pharmaceuticals.

- Alfa Laval LKC Non-return Valve

- Alfa Laval LKC UltraPure

- Alfa Laval LKUV-2 Air-relief Valve

- Alfa Laval SB Self-cleaning CO2 Valve

For a broader valve range, explorer the different product categories: ball valves, butterfly valves, diaphragm valves, double seal valves, double seat valves, regulating valves, safety valves, sample valves, shutter valves and single seat valves.

Ten top tips - Valves

Here are some tips and service videos to show how you keep your hygienic valves in tip top condition

Food Logic

Alfa Laval's hygienic equipment combines high performance with gentle handling to preserve sensitive ingredients and keep up with the food industry trends. The equipment addresses four key challenges; supplying food products to consumers at a competitive price, getting the most from raw materials, reducing waste and emissions, and delivering safe and hygienic food products.

Animations

Visit the animations site and take a look inside a product to see and understand how it works.