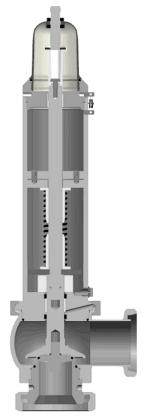

Safety Valve

The Alfa Laval Safety Valve is a versatile hygienic spring-loaded relief valve that prevents pressure buildup in process tanks, vessels and equipment due to blocked discharge, thermal expansion, chemical reactions, or a combination of these events.

Compact safety valve that minimizes the risk of implosion of tanks when a vacuum condition arises

- Safe, reliable operation

- Hygienic design

- Prevents unsanitary leakage and overflow

- Safeguards both personnel and equipment against accidents due to overpressure

- Optional manual or automated overwrite for valve cleaning

This safety valve is ideal for use in the dairy, food, beverage, biotechnology, pharmaceutical and many other industries.

Close at Hand catalogue

The hygienic equipment product catalogue "Close at hand" includes product leaflets, links to animations, brochures and lists for ordering purposes.

CAD portal

The Alfa Laval CAD portal is an essential platform for downloading detailed product information, 2D drawings and 3D product models.

Relieve excess pressure

Pressure can build inside vessels or systems due to blocked discharge, thermal expansion, chemical reactions, or a combination of these events. The Alfa Laval Safety Valve is designed to flexibly relieve excess pressure from vessels or equipment at all times and under any circumstances. As the last and vital component in accident prevention, a high-quality, hygienic safety valve is an essential part of your operations.

Get the perfect fit

Depending on the causes of excess pressure, a different mass or volume flow may need to be discharged. With this type of variable flow, a perfectly fitted safety valve is essential. The Alfa Laval Safety Valve comes in sizes from DN25 to DN100 with a spring-loaded set pressure range between 0.2 and 12.0 bar depending on the size of the valve.

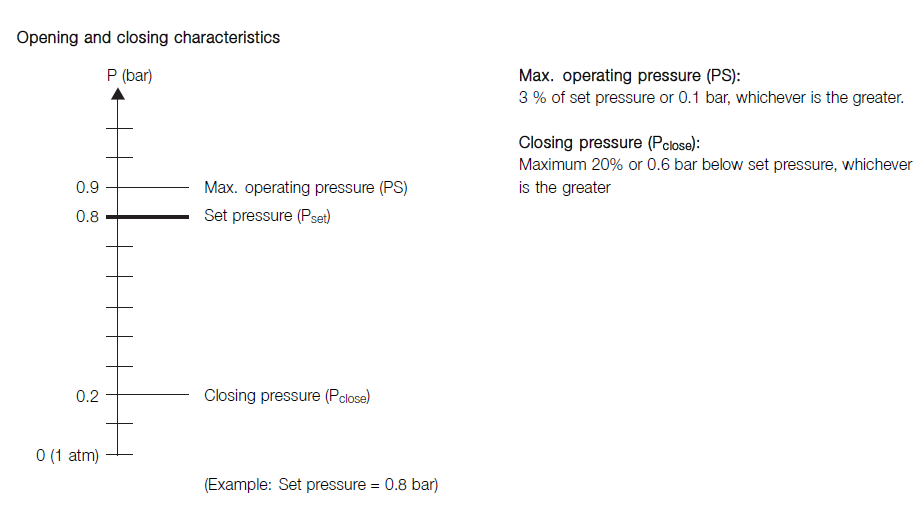

Reliable protection

In a potentially dangerous situation, the Alfa Laval Safety Valve is designed to open at a predetermined set pressure. The compressed spring force, which keeps the valve closed below the set pressure, is forced open when pressure builds up at the inlet of the safety valve. As these forces balance out, the valve will discharge and decrease pressure, ultimately reclosing as the system returns to normal.

Safety Valve

- Dedicated protection. The Alfa Laval Safety Valve delivers reliable protection against costly and devastating accidents.

- PED approved. Calibrated to the desired pressure set point, sealed and delivered with a corresponding PED certificate.

- Hygienic design. Designed to eliminate unsanitary leaks and overflow during and after a pressure spike.

Service

Our dedicated Global Service Network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment. We can work with you to integrate our services into an Alfa Laval Service Agreement for predictable and worry-free operations.

Learn more about our service offer Troubleshooting

Serial number search Certification

Please contact us with any queries or questions.

How it works

Construction

The Alfa Laval Safety Valve comes in sizes from DN25 to DN100 with spring loaded set pressure range from 0.2 to 12.0 bar. The valve can be pneumatic or manually operated. The Alfa Laval Safety Valve is calibrated to the desired pressure set point, sealed and delivered with a corresponding PED certificate.

Operating principle

The closing force in the Alfa Laval Safety Valve is applied by a compressed spring with a set pressure greater than the operating pressure.

In a potentially dangerous situation, the valve will open at the predetermined set pressure. The spring force acts in the closing direction and the force created by the pressure at the inlet of the safety valve acts in the opening direction. At a certain point, these forces will be balanced out and the valve will make an initial discharge to relieve the pressure.

Part of a broad valve range

Alfa Laval offers a comprehensive range of valves intended for hygienic applications in various industries including dairy, food, beverage,home care, personal care, biotechnology and pharmaceuticals:

Food Logic

Alfa Laval's hygienic equipment combines high performance with gentle handling to preserve sensitive ingredients and keep up with the food industry trends. The equipment addresses four key challenges; supplying food products to consumers at a competitive price, getting the most from raw materials, reducing waste and emissions, and delivering safe and hygienic food products.

Ten top tips - Valves

Here are some tips and service videos to show how you keep your hygienic valves in tip top condition

Subscribe near Newsletter

Stay updated on important sustainability issues and opportunities in your industry and processes!

Animations

Visit the animations site and take a look inside a product to see and understand how it works.