Aalborg AV-14

The Alfa Laval Aalborg AV-14 (Waste Heat Recovery Unit after Gas Turbines) is designed to efficiently recover energy from the exhaust gases downstream from gas turbines. It can be used as an economizer or to produce hot water or hot oil for power generation, heating and process duties.

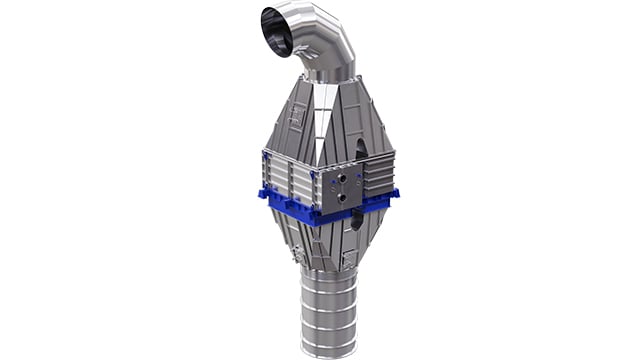

Aalborg AV-14 waste heat recovery unit after gas turbines

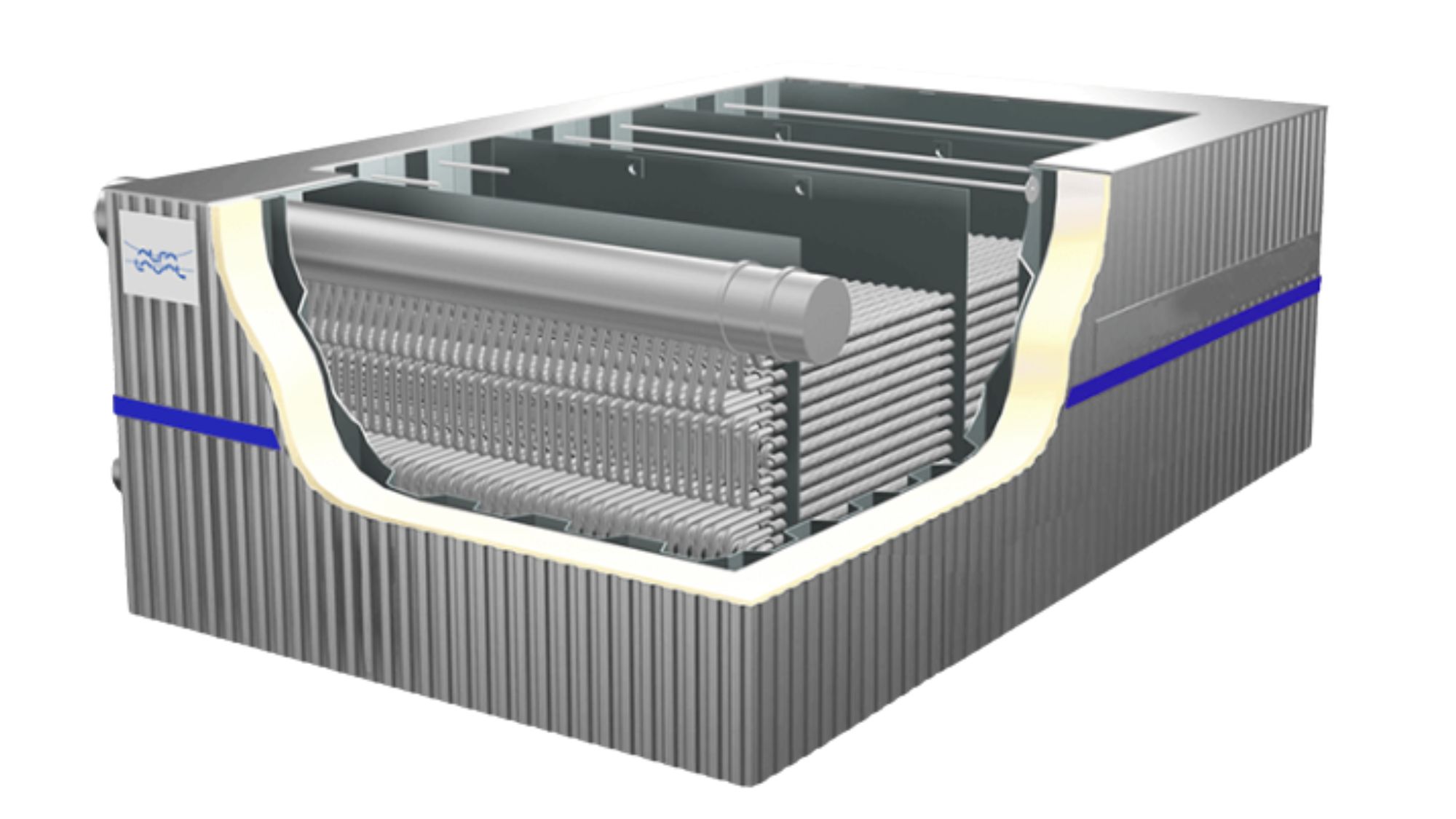

- Efficient and well scalable heating surface design that reduces weight and footprint

- Design to suit gas turbines, also in the field of oil and gas, offshore markets

- Delivery with silencer and ductwork

- Delivery with integrated bypass, with modulation and part-load controls

- Well-proven and reliable technology for easy operation and maintenance

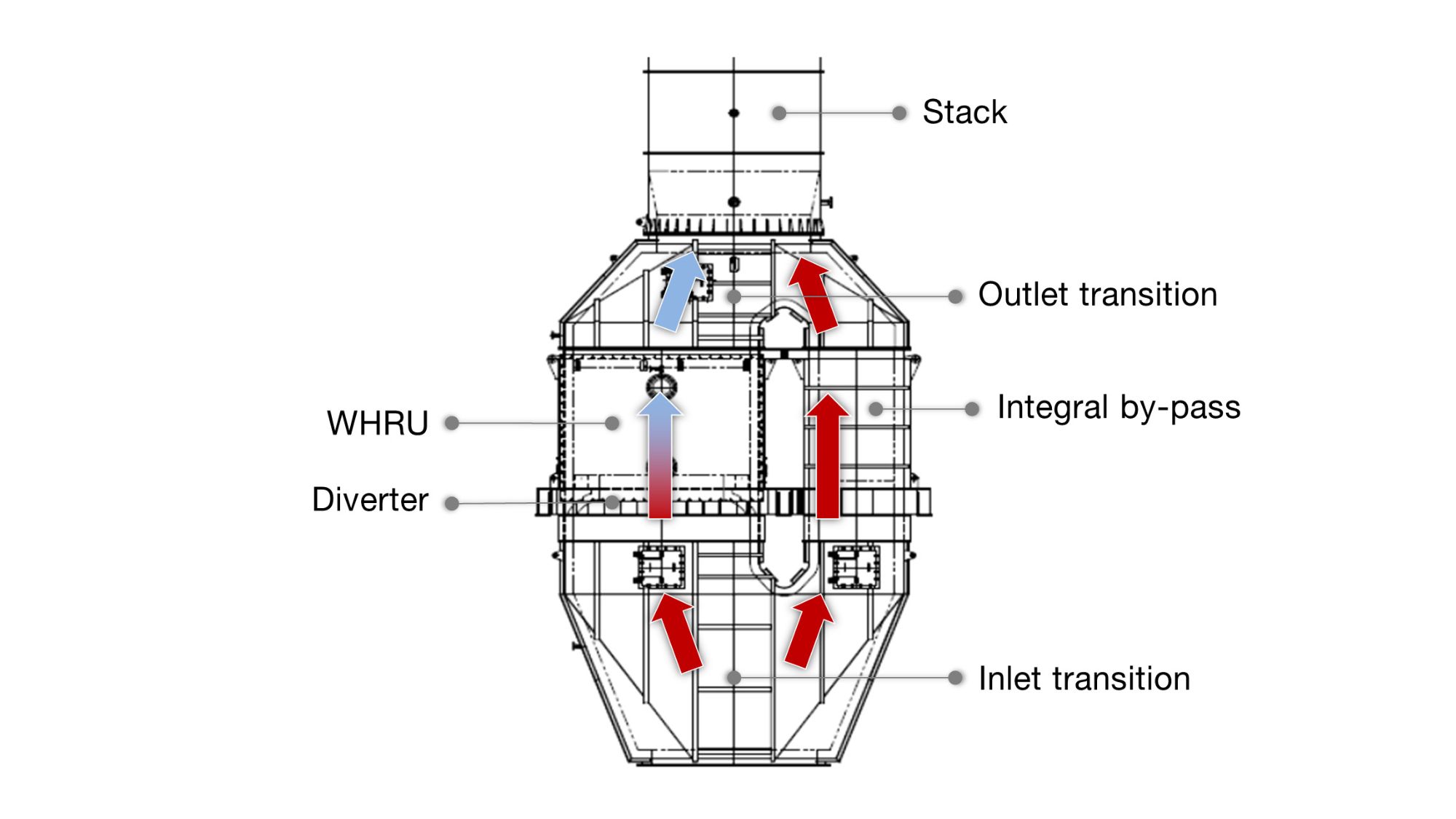

The Aalborg AV-14 can be supplied as a unit with or without integrated bypass and as a complete system including silencer, ducting and stack. Its design offers the best solution with respect to efficiency, accessibility, weight and footprint. Other advantages of the Aalborg AV-14 include its low maintenance costs and high reliability, as well as the simple control that allows easy integration.

The Aalborg AV-14 can be used for heating up of water, water-steam, thermal oils and/or TEG or MEG water.

How it works

Standard scope of supply

- WHR-unit

- Insulation & cladding

- Ducts

- Stack

- Silencer

- Expansion joints

- Diverter

- Control system

- Instrumentation

- Deaerator/feed water tank

- Feed water treatment system (incl. chemical dosing unit)

- Bypass – external or internal bypass

- Documentation (relevant manuals, certificates etc.)

Technical data − typical values* |

|

|

Exhaust gas flow: |

170 kg/s (375 lb/sec) |

|

Exhaust gas temperature: |

Typically < 560°C (1040 F) |

|

Pinch point: |

Typically 15-20 °C (59-68 F) |

|

Design pressure: |

≤ 50 bar (725 psi) |

|

*Values are project dependent |

|

Documents

Service

We provide full support for our waste heat recovery systems. Our support covers their entire life cycle, beginning with design, installation and commissioning and extending past warranty throughout the service life.

Alfa Laval Service Agreements will help the operators of the systems. A fixed-period Service Agreement makes operation planning and cost projections more secure. A well-crafted maintenance strategy offers transparent cost control and safeguards performance, lengthening your equipment’s lifespan and reducing your total operating costs. Preventive maintenance is the key to reliable performance. Our Preventive Maintenance Programme comprises annual and 30-month services that comply with regulatory inspection schedules.