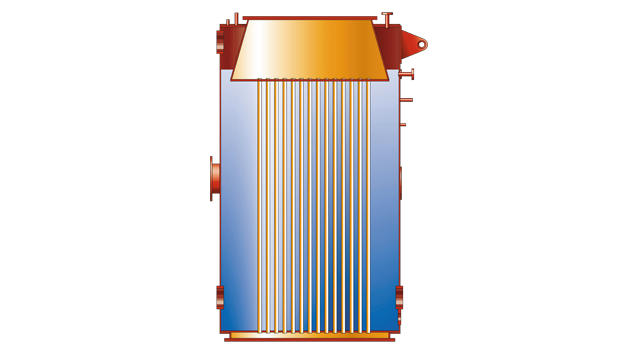

Aalborg XS-2V

The Alfa Laval Aalborg XS-2V is a robust smoke-tube economizer. Easy to install, operate and maintain, it reduces the use of the fired marine boiler by recovering heat energy that otherwise would be lost through the exhaust gas. The Aalborg XS-2V is similar to the Aalborg XS-7V, but it is equipped with its own steam space, which makes it a complete exhaust gas boiler. Its proven design includes a dual-inlet option, which creates high installation flexibility.

Dual-inlet flexibility and steam independence

- Simple and reliable design based on smoke tubes – with its own steam space

- Easy improvement of Carbon Intensity Indicator (CII)

- Short payback time (typically 1–2 years) through up to 25% fuel savings on the fired boiler

- Reduced wear and maintenance on the fired boiler

- Dual-inlet option allowing connection of two engines to one economizer

Reduce fuel costs and emissions

The Aalborg XS-2V is part of Alfa Laval’s broad waste heat recovery portfolio, which builds on over 40 years of waste heat recovery experience. We take a holistic approach, helping you identify the optimal economizer setup for your particular vessel.

Our solution is always tailored to your steam requirements, the amount of exhaust gas and your vessel’s unique characteristics. It can include:

- Smoke-tube or water-tube economizers

- Single-inlet or dual-inlet solutions

- Compact economizers to minimize installation footprint

You can always count on a rapid return on your waste heat recovery investment. Our broad portfolio, combined with our deep expertise, is your assurance of the most cost-effective, reliable and energy-efficient waste heat recovery solutions.

The economizer is carried out with the smoke tubes welded to the tube plates at both ends, and this robust design can, in emergency cases, withstand running dry.

The Aalborg XS-2V comes with its own steam space and is able to operate independently from the oil-fired boiler/steam drum.

The sizes of the economizers depend on required steam capacity, amount of exhaust gas, temperature, and working pressure.

Characteristics

-

Vertical smoke tube exhaust gas economizer

-

Own steam space or forced circulation

-

Designed to utilize thermal energy in exhaust gases

-

Quick start up

-

Simple and automatic opeation

-

Easy maintenance

-

Standardized components

-

All-welded contructions

-

Integrated silencer as an option

- Compact and easy to install

Design data

- Steam capacity: 0.5 - 5 t/h

- Heat capacity: 0.3 - 4 MW

- Design pressure:10 bar(g)

How it works

The boiler is supplied complete with manholes, manhole covers, inspection and mudhole doors, supporting brackets and necessary fittings for lifting and supporting. Spare parts and tools are supplied in accordance with the classification societies' requirements.

The boiler is equipped with flanges for bolting together with inlet and outlet gas ducts. Inlet and outlet gas ducts can be supplied as an option.

The boiler is built with the tubes welded to the tube plates at both ends and it can, in emergency cases, withstand running dry.