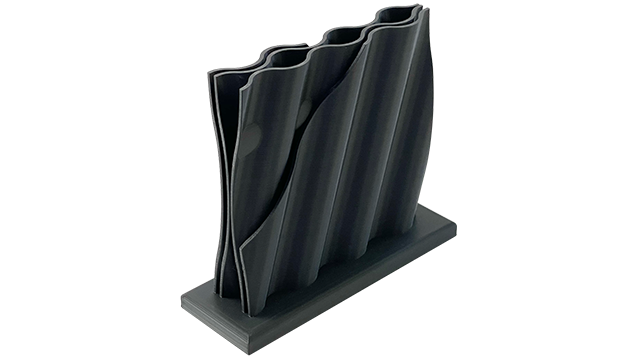

Welded plate-and-frame heat exchangers

Packinox plate-and-frame heat exchangers are the perfect choice for heat transfer duties in processes with large flows, high temperatures and high pressures. Find out more about the advantages of plate-and-frame heat exchangers below.

Outstanding thermal efficiency

- Lower CAPEX – A single Packinox can replace several large shell-and-tube heat exchangers

- Lower OPEX – The exceptional heat recovery brings substantial energy savings

- Low maintenance costs thanks to minimal fouling

- Low pressure drop

- Reliable, proven technology

A single Packinox outperforms systems consisting of multiple large shell-and-tubes, both in terms of heat recovery and investment costs.

And thanks to the innovative design of Packinox+, the latest addition to the Packinox range, you can now optimize for highly asymmetric flows, opening up for a wide range of demanding duties.

FlexFlow – for asymmetric flows

Until recently, Packinox heat exchangers were targeting duties with fairly symmetric flows. With the introduction of FlexFlow design the benefits of Packinox technology are now extended to a much wider range of applications and industries.

Packinox+

A Packinox+ heat exchanger is the optimal solution for large-scale heat recovery in industrial processes with high pressures and temperatures. The unique, welded plate design makes it possible to recover more heat in a single Packinox+ than in a system comprising multiple large shell-and-tube heat exchangers. The result is significant energy savings, reduced footprint, and lower CO2 emissions.

Packinox plate-and-shell heat exchanger

Alfa Laval Packinox is also available in a plate-and-shell configuration, which is suitable for applications with higher pressures and temperatures. The plate-and-shell model also features Alfa Laval´s patented Spray Bar system, which optimizes liquid injection in gas streams.