Carboset

The Alfa Laval Carboset™ and Carboset™ Mini are beer carbonation systems, both excellent for accurate, automatic and low-maintenance beer carbonation and carbonation of other beverages, including soft drinks. Our beer carbonation machine is designed to fit the desired level of carbon dioxide in beer as well as the need for nitrogen in beer to match your perfect recipes.

An efficient, automatic and robust carbonation machine

- Eliminates the risk of bubble formations

- Outstanding blending accuracy

- Efficient dissolving of carbon dioxide

- Versatile and adaptable to different process requirements

- Automatic control and low maintenance

How it works

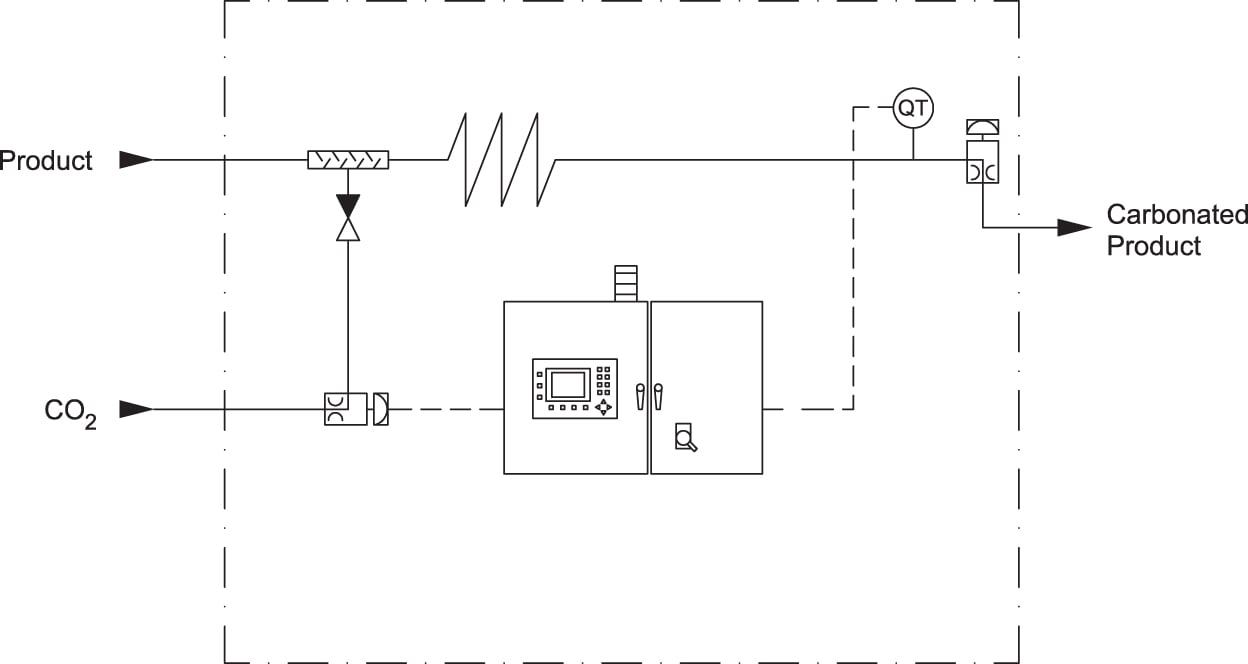

How the carbonation system works

Achieving a desired and consistent concentration of carbon dioxide in beer is not difficulty. With our carbonation system, CO2 is injected directly into the beer via a specially designed static mixer, which makes sure the gas is efficiently dissolved. You set the required carbonation level at the control panel, and flow meters, CO2 meter and a control valve ensure the exact amount of gas is dosed.

The module includes a holding cell combined with a back-pressure valve, so all gas is completely dissolved when the beer leaves the module.

A typical application could be carbonation to exactly 6.0 g/l CO2 of incoming beer at a temperature of 2°C and a pressure of 4 bar (g).

FAQs

Can an Alfa Laval Carboset™ operate in front of a filler and/or without buffer tank?

Yes. It is important to note that, in doing so, there is a risk of variations in the CO2 content when the filling line is stopping and starting. However, the risk is minimized due to the usual presence of the buffer volume in the filling machine.

Is it possible to install a Carboset just after a separator?

Yes, however the Carboset must be able to communicate with the separator in order to handle the interruption in product flow during discharge. Before the separator discharge, the Carboset memorizes and saves the position of the CO2 dosing valve, and initiates the same dosing conditions as soon as the flow of product begins again.

How quickly can I change the CO2 concentration in the product?

The CO2 setpoints for different recipes are stored in the Carboset control unit. To change the CO2 concentration in the product, you simply need to choose the recipe that corresponds to the concentration that you want to use. This only takes a few seconds.

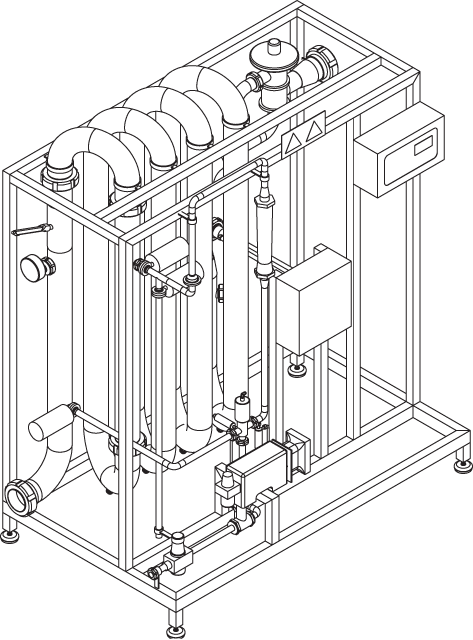

Carboset™

The Carboset™ is among the beverage systems and supplies that are developed in cooperation with the brewing industry. It is a well-proven, robust, compact beer carbonation module and a reliable, efficient and hygienic solution to improve the quality of beer and other beverages.

Dimensions*

- (LxWxH): 1.5m X 1.0m X 2.3 m

- CO2 at outlet: Up to 7 g/l (final product)

*Exact dimensions vary depending on capacity range.

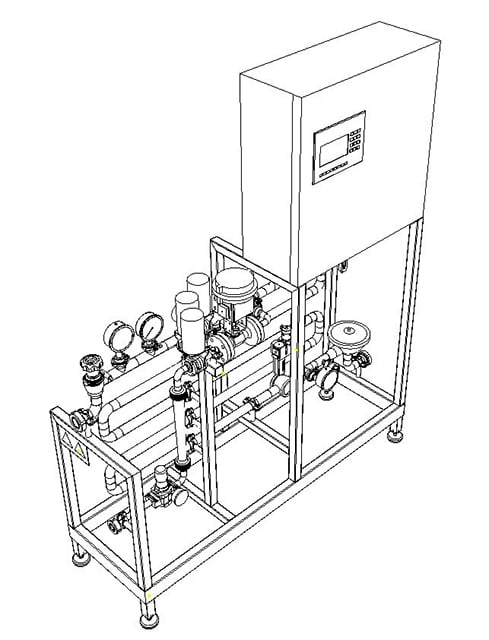

Carboset™ Mini

Designed with the craft breweries in mind. This special module helps you get the right level of carbon dioxide in beer and solves the problem of low or inconsistent carbon dioxide concentration in your beer. You may store several recipes in Carboset™ Mini with individual settings for different beers and filling lines.

Dimensions*:

- (LxWxH): 1,600 x 500 x 2,000 mm

- CO2 at outlet: 4-6 g/l

Service

Food system services

Alfa Laval Food system services help extend the performance of your food systems by maximizing the performance of your processes. This enables you to:

- Continually improve your operations to maintain competitive advantage

- Focus on uptime, optimization and availability

- Maximize return on investment throughout the life cycle of your food systems

Learn more about our service offer for food systems