Sterile filtration module

The Alfa Laval Beer Sterile Filtration (BSF) module filters your beer, so you achieve 100% bacteria retention without thermal degradation – and without affecting your product’s flavour. This is thanks to our unique membrane beer filtration system and Sartorius filtration cartridges.

Our beer filter provides gentle treatment and guaranteed taste

- Filtration with complete removal of micro-organisms that can affect beer quality and flavour without thermal degradation

- Low oxygen pick-up at start-up and close to zero product losses

- Maximum process security

- Easy-to-operate beer filtration

- Easy to integrate into existing production lines

Sterile filtration of beer with optimal safety: For maximum safety, each Beer Sterile Filtration membrane cartridge is certified, and the beer filtration system performs an integrity check before processing a batch. There is no need for a buffer tank, meaning a small footprint that saves valuable space.

Beer Sterile Filtration Module (BSF)

A well-proven, complete and fully automated beer sterile filtration module for large breweries for maximum performance and minimum down time.

Beer Sterile Filtration Mini Module (BSF Mini)

A compact manual beer sterile filtration module designed for craft brewers.

How it works

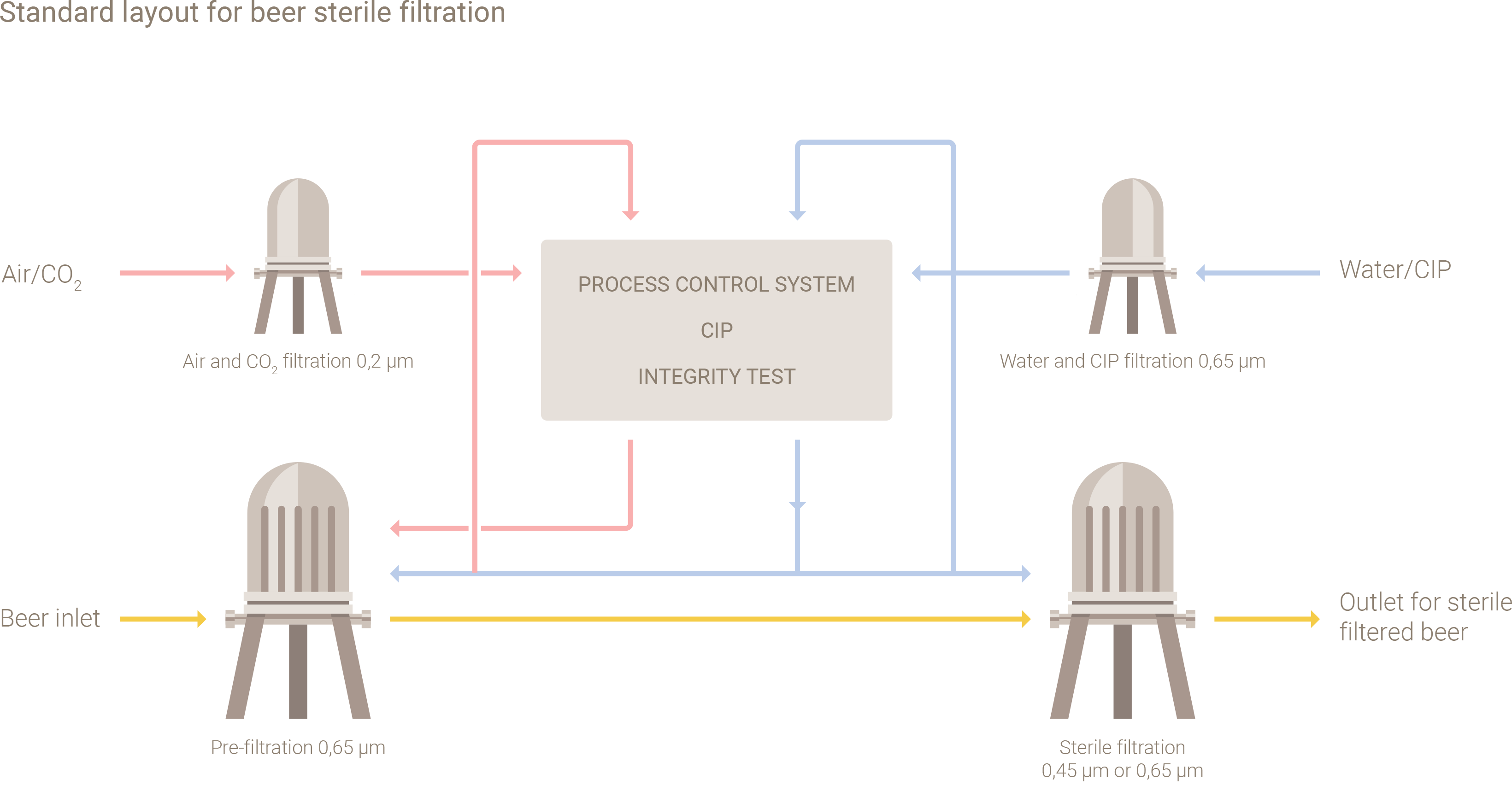

A complete beer sterile filtration solution

We offer complete systems for sterile beer filtration including pre and sterile filtration of beer, CIP and water filtration and sterile filtration of gases. The filtration systems are specifically designed to maximize performance of Sartorius sterile filtration cartridges.

These systems include a pre-filtration step with Sartorius depth filtration cartridges that maximize the quantity of beer that passes through the sterile filtration cartridges, boosting productivity.

Bright beer is initially filtered with Sartorius depth filtration cartridges with a nominal retention rate of 0.65 μm, followed by a sterile beer filtration step using Sartocool® filtration cartridges with absolute retention rates of either 0.45 μm or 0.65 μm. After removing the microorganisms, the beer is routed directly to the filler.

Alfa Laval’s beer sterile filtration systems are optimized for effective CIP of the beer pre-filtration and sterile filtration cartridges. These are cleaned and regenerated on a regular basis with standard caustic solutions. The complete beer filtration system, including cartridges, is sterilized with hot water. Any water and CIP liquids that come in contact with the sterile filtration cartridges are pre-filtered to eliminate any risk of loading the cartridges with particles.

The beer filtration system integrates a supply of sterile gases for integrity testing and to minimize beer losses at the beginning and end of production runs. In addition, the entire beer filtering system is automatically controlled to ensure the best possible process conditions, maximum reliability, safety and the lowest possible costs for your beer production.

Service

Food system services

Alfa Laval Food system services help extend the performance of your food systems by maximizing the performance of your processes. This enables you to:

- Continually improve your operations to maintain competitive advantage

- Focus on uptime, optimization and availability

- Maximize return on investment throughout the life cycle of your food systems