AromaVap

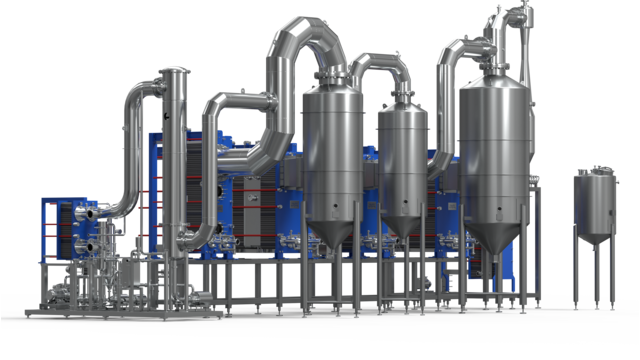

Rely on the Alfa Laval AromaVap plate evaporator for fast, gentle and highly effective concentration of heat-sensitive fruit and berry juices and herbal extracts while preserving valuable aromatic compounds. Processing under vacuum conditions using once-through flow keeps process temperatures low, eliminating the need for recirculation and minimizing the holdup volume. This helps ensure fast startup, minimum residence time, and short emptying time as well as high product quality and yield.

Fast, gentle and highly effective concentration of delicate, heat-sensitive juices and herbal extracts with minimal product loss

- Fast, effective once-through concentration of heat-sensitive fruit and berry juices and herbal extracts

- No loss of product quality during concentration due to gentle handling and low temperatures

- Extracts, concentrates and collects aromatic compounds with no risk of loss with the vapour

- Simple operation with easy-to-access, easy-to-clean heat transfer surfaces

- Hygienic, easy-to-clean design that meets most global food industry standards

Intensify the flavours of heat-sensitive juices as well as herbal extracts with the Alfa Laval AromaVap plate evaporator. This once-through evaporator concentrates product under vacuum conditions while maintaining low process temperatures. This prevents the need for recirculation and reduces hold-up volumes. Low temperatures and short residence times maximize product quality and minimize product loss.

A specially designed aroma extraction module separates and concentrates volatile aromatic compounds, preventing the loss of valuable by-product.

Extremely versatile and compact, the AromaVap plate evaporator is easy to install, operate and maintain and ensures high product quality and yield.

Pilot testing and rentals of evaporation systems

Try before you buy. Get expertise and advice from Alfa Laval engineers for the optimum configuration for your evaporation system, including:

- Detailed water analysis and characterization

- Process and water chemistry modelling

- Benchmark and/or pilot testing for moderate- to high-risk applications

- Detailed material compatibility evaluation

- Sample analysis

- Pilot tests

Visit the Alfa Laval Materials Technology & Chemistry Lab and Test Centre in Lund, Sweden, the Alfa Laval Innovation and Test Centre in Nakskov, Denmark, or rent one of our mobile pilot evaporation systems to conduct onsite trials at your plant.

Key products

Service

Food system services

Alfa Laval Food system services help extend the performance of your food systems by maximizing the performance of your processes. This enables you to:

- Continually improve your operations to maintain competitive advantage

- Focus on uptime, optimization and availability

- Maximize return on investment throughout the life cycle of your food systems

Applications

Flexible configuration and capacities

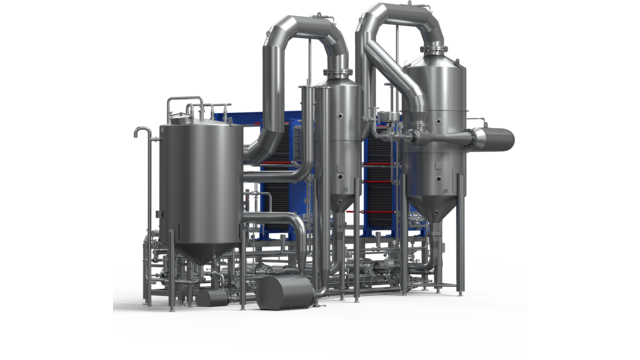

Easily configure your AromaVap plate evaporator to your required evaporation duty in terms of processed product, water removal and in/out concentrations, or let Alfa Laval engineers do it for you. Unlike shell-and-tube evaporators, where are capacity is fixed once installed, AromaVap accommodates changing process requirements. To adjust capacity, simply add or remove plates in the existing frame.

Compact and cost-effective

Compared to shell-and-tube heat exchangers, the AromaVap has a much more compact footprint, simplifying operations and maintenance and reducing costs. Low hold-up volumes with fast start-up and emptying times translate into more uptime and higher yield.

Easy to inspect, easy to clean

Easily inspect the inner workings of the AromaVap from the ground floor. Simply remove the tightening bolts and roll back the pressure plate to access the heat transfer surfaces. No heavy tools are required. Glue-free, clip-on gaskets ensure tight seals and trouble-free replacement. Due to its low hold-up volume, the AromaVap requires only a small amount of cleaning media for effective Cleaning-in-Place (CIP), further reducing costs.

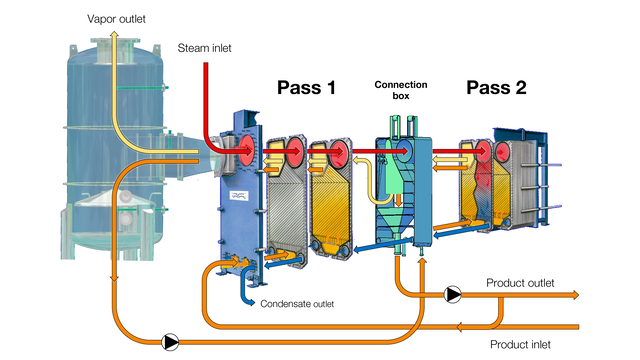

How the AromaVap plate evaporator works

The Alfa Laval AromaVap plate evaporator is a rising thin film plate evaporator. Product flows along the heating channels and evaporates, releasing a portion of its water content. Contact time of the product with the heating surface is limited due to the turbulence and high fluid velocity. The vapour/liquid mixture leaves the plate heat exchangers and enters a vapour separator, which separates the vapour phase and directs it to the upper outlet. The liquid phase collects at the bottom of the separator and is transferred through an outlet for subsequent processing in the next effect or to the final extraction point.

To prevent recirculation and overtreatment of the product, all effects work with once-through flow, using connection boxes, where necessary. The connection boxes function as intermediate vapour separators, removing the separated vapour and preparing the liquid phase for the next evaporation stage.

Fully automated, the AromaVap uses a centralized programmable logic controller (PLC) to regulate the feed flow of product and steam in order to extract the final product at the required concentration from the final stage of evaporation.

The use of an aroma concentration and separation unit enables the processing of the aromatic condensate extracted from the evaporator, thereby enriching the aroma content and making it available as an ingredient for further processing.

You might also be interested in...

Explore our range of evaporators

Alfa Laval offers a wide range of evaporation systems from plate evaporators, and rising film evaporators to tubular evaporators and falling film evaporators. Find out what would work for your evaporation needs.