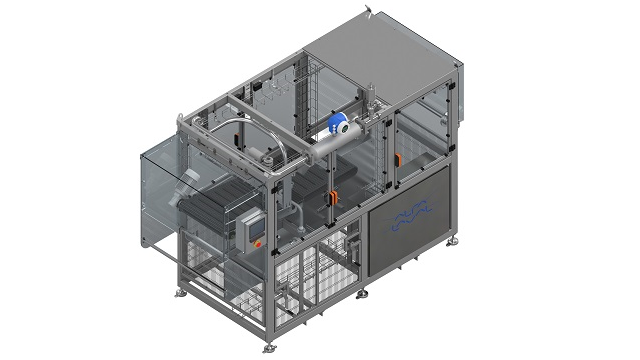

Astepo piccolo filler

Use the limited floor space at your filling and packaging facility wisely with the Alfa Laval Astepo piccolo filler. This compact, non-aseptic semi-automatic filling machine with manual bag-in-box infeed transfers volumes of pumpable liquid and viscous food and non-food products at up to 200 bags per hour. Flexible and simple to operate and maintain, this filling system easily adapts to bag size, cap type or packaging design. Suitable for the dairy, food, beverage, wine and other industries.

A compatibility that no one else can match with our bag-in-box fillers

- Highly flexible, no matter the bag size, cap type or packaging design

- Ensure product safety and extend shelf life while preventing oxygen pick-up during hot and cold fills

- Compact, fits-anywhere hygienic design with highly effective cleaning

- High, efficient output with accurate, fast changeovers and low maintenance

- Global expertise with a solid local service and support network

Rely on the Alfa Laval Astepo piccolo filler, wherever space is limited, to increase filling speeds while reducing the time, effort and costs associated with packaging liquid or viscous food and non-food products. Boost uptime and output using a manual bag infeed with a one-inch fitment, automated operation and efficient changeovers between bag sizes, closures and cleaning cycles.

Choose between one or two filling heads, bag sizes from 2–20 litres in size, and various cap types sanitized through cost-effective cleaning-in-place procedures.

This semi-automatic bag-in-box filler has options for demanding applications as well as bag sizes up to 200 litres.

How does the Alfa Laval Astepo piccolo filler work?

The operator inserts an empty bag into the spout holder, which activates the filling sequence. The system then removes the cap and inserts the product valve. Any residual air is removed by the vacuum, and the product then begins to flow into the bag.

Upon completion of filling the desired volume of product into the bag, the filling machine automatically shuts off flow of product. A puff of nitrogen follows. The bag is recapped, and the filled bag is ejected from the holder to one side.