Flexitherm

Flexitherm™ is an automatic pasteurization machine for beer. It uses a pasteurization method that eliminates microbiological spoilage, achieves the right pasteurization temperature and preserves the quality and shelf life of beer and other carbonated drinks over a variable flow range. This pasteurization method is tailored to provide optimal, efficient thermal treatment of beer to be sent to aseptic filling systems.

Solutions for beer pasteurization - Eliminate micro-organisms and preserve beer quality

- Reliable pasteurization units (PU) control system for stable product treatment (PU variations within +/- 10% of target level during constant operation

- Minimum site work as the module is self-contained and pre-assembled with automatic control

- Designed for CIP, the sanitary and compact module requires low maintenance, minimizing downtime

- Effective energy recovery up to 95%

- State-of-the-art automated control system featuring process continuously refined control refinements

Flexitherm™

This beer pasteurization equipment is ideal for high capacity brewer processing. It cuts operation costs by recovering up to 95% of heat*.

Specification

Approximate dimensions and weight depending on capacity range:

For capacity = 40hl/h,

Dimensions (LxWxH): 3.2m x 2.0m x 2.2m

For capacity = 400hl/h,

Dimensions (LxWxH): 4.0m x 3.6m x 2.6m

*Compared to a traditional tunnel pasteurizer, it improves overall water consumption by up to 0.42hl/hl, and improves the energy usage ratio by 5MJ/hl.

Flexitherm™ Mini

Designed especially for craft brewers, Flexitherm™ Mini lets you save several recipes in the same unit with individual settings for different craft beers.

Specification

Capacity: 5-50 hl/h (3 different modules)

Dimensions (LxWxH): 4,000 x 2,000 x 2,000 mm

Happy customers

According to Art Oestrike, president at Jackie O's, "Barrel ageing beers is a fickle business. You take this big, beautiful imperial stout or barley wine and throw it into a freshly dumped bourbon barrel and let it sit in our warehouse. A year and a half after packaging it, they start to turn sour. They don't taste good."

Watch the video to hear how Flexitherm Mini 'flipped the barrel aging programme on its head'.

How to pasteurize beer with Flexitherm

Alfa Laval Plate Heat Exchanger for beer pasterurization

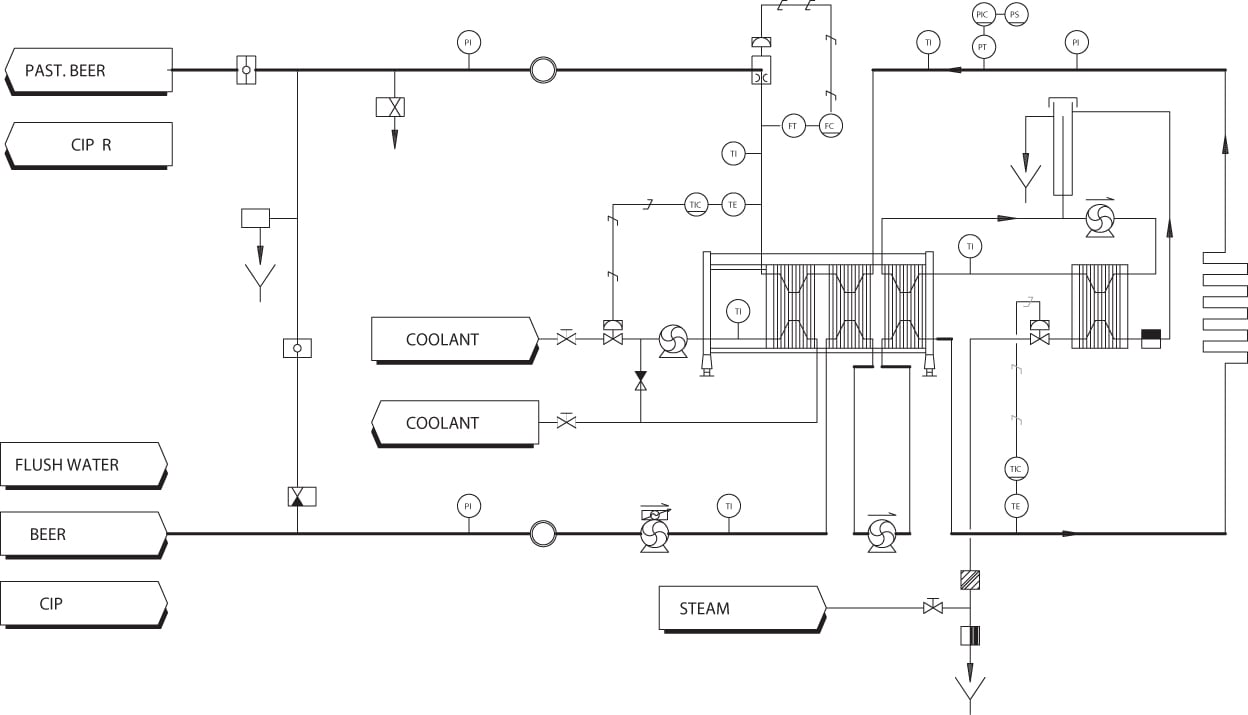

The Flexitherm plate heat exchanger (PHE) beer pasteurizer system is used for eliminating or reducing the number of live micro-organisms in the product with the aim of improving microbiological stability and to increase shelf life of the product. The required heat treatment is achieved through a combination of temperature and holding time.

In the PHE, the cold, unpasteurized beer is heated to the pasteurization temperature in two steps.

Depending on selected configuration, the flow through the FLEXITHERM module can continuously be adjusted to cater for variation in filling machine demand. The Flexitherm module is fully automated with a PLC system controlling the plant operation.

FAQs regarding beer pasteurization

Can an Alfa Laval Flexitherm™ solve my product shelf-life and/or stability issues?

Yes, if the issue is related to the presence of living microorganisms in the beer and the contamination occurs upstream. If the stability issue is related to something else or occurs downstream at the filling line or packaging area, for instance, the Flexitherm will not be able to solve the issue. If it is a colloidal stability issue like those experience with German wheat beers, then the process temperature must be raised beyond the level that a standard Flexitherm can handle. If this case, please contact Alfa Laval Brewery Systems so we can review and recommend a solution.

Is it possible to use hot water instead of steam as a heating media?

The Alfa Laval Flexitherm works as a standard with steam. If no steam is available, it is possible to modify the Flexitherm (at an extra cost) and run it using hot water. The temperature of the hot water must be at least 90°C in order to sterilize the interior of the Flexitherm.

Can the Alfa Laval Flexitherm solve my contamination issues?

That depends. Yes if the contamination occurs upstream, and no if the contamination occurs after the Flexitherm, such as at the filling line, final packaging line, or receiving tank.

What is the typical commissioning time for the Flexitherm?

The typical commissioning time varies, depending on the use of a buffer tank. Commissioning a Flexitherm without buffer tank and routing generally takes about five days on site. It takes about 10 days on site when the Flexitherm has a buffer tank and routing in front of a filler.

How does the Flexitherm perform if my filler requires a certain pressure and/or flow rate?

A standard Flexitherm pasteurization machine is equipped with buffer tank and routing to ensure that the pressure after the buffer tank is constant—regardless of flow rate. This ensures that the requirements of the filler are met.

Can I pasteurize milk with a Flexitherm?

No. The Alfa Laval Flexitherm is not intended for milk pasteurization. Please contact our Global Alliance partner Tetra Pack for this application.

When are the electrical drawings available?

The electrical drawings are usually ready and available for your use about four weeks after you place your order.

Why is the maximum allowed deaeration water temperature set to 15°C?

The deaeration water temperature should be as close as possible to the temperature of the beer. If the temperature is too high, the system’s temperature variations will be too large when switching back to beer.

Can I apply my specific Cleaning-in-Place (CIP) recipe to the Flexitherm ? Can I use lye and acid?

The Flexitherm can tolerate any standard brewery CIP regimes. This includes caustic and acid cleaning. All wetted parts that come into contact with the product are made of stainless steel and all gaskets are made of EPDM. To be 100% sure, if you use an oxidative or chlorine-based cleaning regime, Alfa Laval recommends a visual inspection of the unit’s interior to identify any risk of corrosion.

I’ve heard other beer pasteurization suppliers are introducing sterile gas filters for air and CO2 to their beer pasteurizers. Will Alfa Laval also be doing the same?

Alfa Laval is aware of that other beer pasteurization suppliers are offering craft brewers sterile gas filters. However, we decided to remove this option for the Flexitherm Mini for the sake of price and simplicity. Based on experience, we know that sterile gas filters are not critical features to prevent contamination. The sterile gas filter is available as a standard option on our core range and, upon request, we can also offer sterile gas filters on the Alfa Laval Flexitherm Mini.

Can I install the Flexitherm just after my separator?

No. A Flexitherm requires the feed beer to be constant and maintained at a minimum required pressure to ensure that the pressure within the system during pasteurization is consistently high. Without uniform high pressure in the system, there will be cavitation issues, pressure drops and CO2 breakouts in the system.

Service

Food system services

Alfa Laval Food system services help extend the performance of your food systems by maximizing the performance of your processes. This enables you to:

- Continually improve your operations to maintain competitive advantage

- Focus on uptime, optimization and availability

- Maximize return on investment throughout the life cycle of your food systems