Foodec Sigma

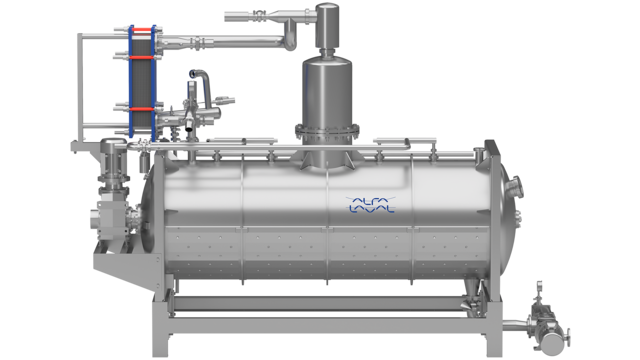

The Alfa Laval Foodec Sigma series of avocado and olive oil decanter centrifuges for two-phase separation help you improve quality and increase yield. Alfa Laval covers the full spectrum of market needs, maximizing oil recovery throughout the flow range while minimizing environmental costs. These compact, reliable and efficient avocado and olive oil decanter units are ideal for the clarification and extraction of oil, making them well-suited for both first and second extraction processes.

Boost olive and avocado oil separation with cost-effective patented technology

- A leading supplier of complete olive and avocado oil process lines, focused on yield optimization, operational reliability and final product quality

- Open and gentle feed zone design “Esbjerg” able to give maximum performance and wear resistance

- High-quality stainless steel is used throughout, complying with global hygiene and legislative standards

- The centrifuge design includes hinged casings for easy opening, maintenance and cleaning

- A global service network in over 100 countries with a comprehensive offering that covers the entire lifecycle of your avocado and olive oil centrifuge

The Foodec Sigma range of decanter centrifuges are engineered to optimize oil extraction efficiency while preserving product quality by preventing temperature rise during separation. Whether you are a small-scale oil miller or an industrial-scale producer, Alfa Laval’s passionate experts can help you increase capacity and profitability in each production cycle, including optimizing re-milling processes. Our proven avocado and olive oil separation equipment, combined with industry knowhow and an extensive global service and support network, ensure reliable production throughout every season.

Building on more than 50 years of experience in developing decanters for oil production, you can trust that qualified help is just a phone call away. Alfa Laval decanters are proven to deliver the highest possible yield, excellent retention of flavours and nutrients, low operating costs and maximum uptime, withstanding tough operating conditions year after year in mills of all sizes.

Need a reliable centrifuge for olive oil extraction or avocado oil separation?

The Foodec Sigma series offers a wide range of capacity options for both industries. Featuring a robust design with a welded box beam frame and high-quality stainless steel, these centrifuges offer easy access for maintenance and cleaning, enhancing the operational reliability and longevity of your avocado and olive oil centrifuge.

- Optimized feed zone position maximizes oil retention time in the unit, enhancing extraction efficiency.

- Special conveyor design improves solids transport and boosts oil recovery.

- Advanced flight design reduces turbulence, optimizing yield and oil clarification.

- Precisely positioned oil outlets minimize heat exposure of the oil during separation, preserving its quality.

- Innovative bowl design ensures easy oil discharge, reducing residual oil inside the bowl.

- Fully protected feed zone with a wear-resistant design enhances durability.

- 360° tungsten carbide solids discharge outlets provide exceptional wear resistance and keep power consumption to a minimum.

- Tungsten carbide conveyor tiles offer superior wear protection, significantly lowering maintenance costs.

- Easily replaceable high-wear conveyor parts simplify maintenance.

- User-friendly serviceability, with a hinged and spring-equipped cover for safe and effortless opening, cleaning and inspection of your decanter for olive oil and avocado oil.

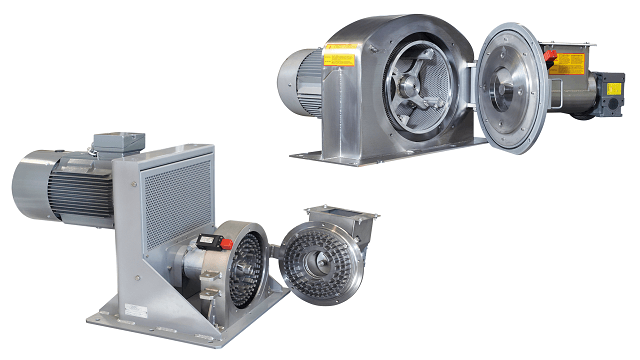

- Variable Frequency Drive (VFD) and customizable automated control solutions ensure operational flexibility and compliance with specific requirements.

- IoT-enabled connectivity provides real-time operating data access to ensure uptime, performance and stability, whether onsite or off.

- Remote support and monitoring enable fast troubleshooting assistance and resolution to maximize uptime during the busy olive and avocado oil processing season. Access Alfa Laval’s connectivity portal for real-time monitoring and alarm notifications, ensuring greater peace of mind.

The features that make the difference

With more than 60 years of experience in solid-liquid separation, Alfa Laval has the expertise to meet the challenges of your centrifuge for olive oil extraction. Packed with features unique to Alfa Laval, Foodec Sigma centrifuges deliver reliable and high-performance solutions for olive oil separation.

EasyLift

Spring loaded cover, that simplifies servicing

The patented spring-loaded hinged design makes it easy to open even the heaviest cover by hand. This also helps ensure quick, safe access for maintenance and service of your decanter centrifuge.

ActiveBaffleDisc

Baffle that improves throughput and performance

The twisted design of the baffle results in better performance and throughput. There is a specific positive impact on solids stuck to the bowl wall during sludge transport towards the outlet zone.

FlightGuard

Robust wear protection for conveyor flights

FlightGuard wear protection consists of tiles welded to the conveyor of your decanter centrifuge, providing robust wear resistance and prolonged uptime in highly abrasive applications.

FeedProtect

Feed zone with replaceable wear protection

The uniquely designed FeedProtect feed zone ensures gentle product acceleration and minimal turbulence, resulting in low abrasion and power consumption. The FeedProtect design is equipped with replaceable wear-protection liners, ensuring high uptime of your decanter centrifuge.

StableInterphase

Unique features secures a stable interphase between solids and liquids

A unique combination of features in Alfa Laval 2- and 3-phase decanter centrifuges, making it possible to achieve the most stable interphase between phases, providing the benefits of the most pure liquid phases and solids dryness.

How does a two-phase olive oil decanter work?

The innovative design of the decanter for olive oil, as for avocado oil, makes sure the incoming olive paste is effectively separated into oil and wet solids.

The olive paste is fed into the bowl of the unit through a stationary inlet tube, and is then smoothly accelerated by an inlet rotor. Separation takes place in a horizontal cylindrical bowl equipped with a screw conveyor. Centrifugal force makes the oil accumulate at the liquid surface, while the solids settle on the inner wall of the bowl, surrounded by the water separated out of the feed stream.

The conveyor rotates at a slightly different speed than the bowl and moves the solids to the discharge ports in the conical end. Olive oil extraction takes place along the entire length of the cylindrical part of the bowl. The oil is returned to the large end for discharge, and then passes into collecting tanks via a filter.

The robust design of the Foodec Sigma ensures reliable performance and smooth operation throughout the entire harvest season. Protective features like FlightProtect, FeedProtect, SolidsProtect and StableInterphase ensures uninterrupted performance, enhance durability and maximize uptime in abrasive applications. Additionally, two-phase machines do not produce any black water, eliminating the need to spread it in the field.

Centrifuges for lower-capacity operations are perfect for small and medium-sized mills. They provide gentle product treatment, minimal heating, and reduced water and energy consumption. On an industrial scale, larger-capacity decanters have revolutionized avocado and olive oil separation, delivering exceptional yields, unmatched capacity and superior product quality.

Olive oil separation success stories

Partnering with Alfa Laval, our customers have developed turnkey extraction plants that ensure every drop of oil meets the highest standards of quality and yield. Discover the remarkable increases in oil output achieved by oil mills in Spain and Italy through their trust in the Foodec Sigma decanter and complementary extraction technologies.

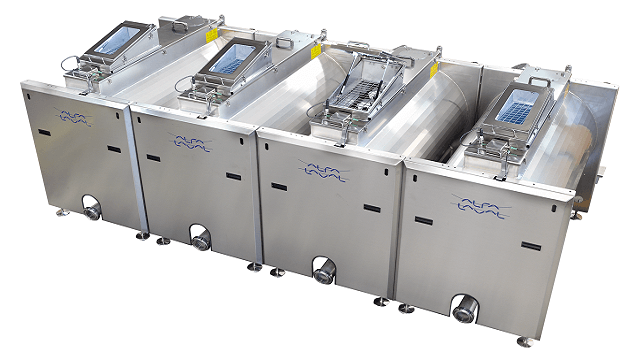

Related products for olive and avocado oil separation

Let us help you

Alfa Laval introduced centrifugal technology to the olive oil industry in 1927, pioneering the extraction process for olive oil separation. Our industry experts can help analyse your unique situation and select the optimal equipment line, configuration and services for your needs and budget.