Culturefuge

Alfa Laval Culturefuge is a range of unique disc stack cell centrifuges and biopharma separators (or complete separation systems) developed especially for gentle cell harvesting of mammalian cell cultures, microbial cells and precipitated proteins. The resultant gentle and efficient feed acceleration avoids destroying shear-sensitive cell membranes, making downstream purification of the target proteins easier and more cost-effective.

Experience the benefits of Culturefuge: solids-ejecting separators and cell centrifuges specially developed for cell culture

- Consistent product quality – fully hermetic conditions effectively eliminate the air-liquid interface inside the cell centrifuge bowl

- Reduced risk of shearing and contamination - unique hollow spindle feed ensures very gentle separation of cells

- Materials meet regulatory requirements for biotech and pharma industries

- Maximum hygiene – flushing nozzles spray outside the centrifuge bowl and inside the frame hood

- Easy scaling up – compact, flexible design can be accurately expanded from pilot plant to production

The Alfa Laval Culturefuge cell centrifuge is available as a skid-mounted, steam-sterilizable system. It includes piping for service and process liquids, along with an integrated electrical system featuring a PLC and a pneumatic unit. Design options include a product contact surface with a Ra value of <0.5 µm.

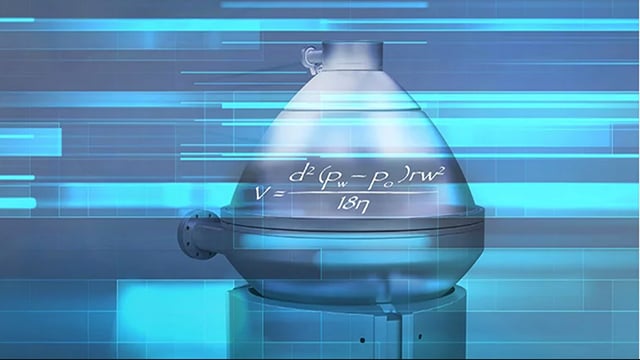

Innovative technology behind Culturefuge cell centrifuge

Hermetic Design™

The Hermetic Design™ is a unique concept that provides various benefits for Culturefuge customers. It enables the gentle acceleration of shear-sensitive biological material through a hollow spindle design, minimizing cell lysis and preventing the release of unwanted intracellular proteins or the destruction of fragile protein precipitates. This enhances yields, improves product quality, and optimizes downstream operations. As a fully hermetic separator, it effectively eliminates any air-liquid interface inside the separator bowl, preventing foaming. With this feature, all internal surfaces remain completely wetted, ensuring efficient CIP. Additionally, flow control devices can be positioned downstream, allowing for the implementation of an obstruction-free, full-bore feed arrangement.

UniDisc™

Alfa Laval UniDisc™ increases disc area for improved separation capacity by up to 30%, while at the same time providing an easy to clean design and never-before-seen degree of hygiene.

Bactofuge®

Bactofuge® enables gentle and speedy processing of high-solids broths, resulting in higher yield, with minimum risk of clogging. In addition to higher separation output, Bactofuge preserves the quality of the solids stream, and allows a flexible and controlled operation. Available in select models of the portfolio.

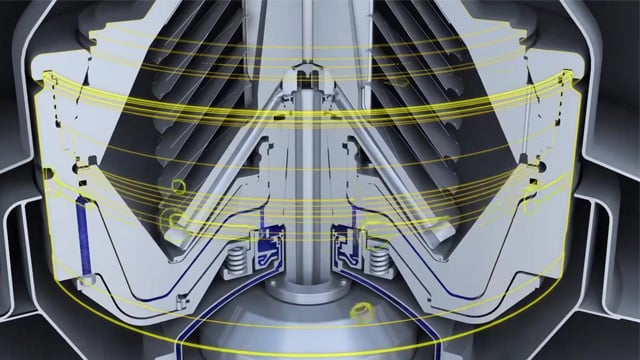

How the cell culture centrifuge works?

The Culturefuge cell separator provides gentle, fully hermetic treatment of cell cultures and other shear-sensitive biological materials. The biological material enters the cell centrifuge through a hollow spindle feed inlet and gradually accelerates as it moves upward to the disc stack, where separation occurs in the rotating centrifuge bowl. The separated liquid phase exits through the liquid outlet at the top of the bowl, while the collected solids are intermittently discharged from the periphery of the bowl. During normal operation, operating water keeps the sliding bowl bottom closed against the bowl hood. During discharge, the sliding bowl bottom drops for a fraction of a second, allowing the solids to be ejected through the discharge ports.

Scalable cell culture centrifuge

Ideal for cell culture fermentation and continuous cell harvesting under hermetic conditions, the Culturefuge cell centrifuge delivers consistent product quality. In addition, it can be accurately and reliably scaled up from use in pilot plants to full-scale production.

Hygienic design

Culturefuge cell centrifuges are made with high-quality materials that meet strict industry regulations. Thanks to their Hermetic Design, they maintain a fully sealed environment, reducing the risk of contamination and ensuring superior hygiene. They are also designed for easy cleaning and sanitation without the need for complicated disassembly. With Sterilization-in-Place (SIP) and Cleaning-in-Place (CIP) systems, the centrifuge can be cleaned automatically, maintaining a hygienic process. Additionally, flushing nozzles spray water inside and outside key components—like the centrifuge bowl and frame hood—for maximum cleanliness.

Complete separation system

The Alfa Laval Culturefuge cell centrifuge comes as a ready-to-use, skid-mounted system. It includes a disk-stack separator on a sturdy base with a horizontal drive shaft, worm gear, lubricating oil bath, and hollow vertical bowl spindle. The system also features piping for service and process liquids. For easy operation, it comes with a built-in electrical system, including a starter, programmable logic control (PLC), and a pneumatic unit. The separator is designed to meet major pressure vessel standards, including ASME and PED, ensuring safety and compliance with industry regulations.

The Culturefuge range

Culturefuge 100

- For pilot plants and small-scale production

- Capacities from 200 to 2,000 l/hr

Culturefuge 200

- For medium scale production with capacities ranging from 1,000 to 5,000 l/hr

Culturefuge 300

-

For medium to large scale production with capacities ranging from 2,000 to 8,000 l/hr

Culturefuge 400

- For large scale production with capacities ranging from 3,000 l/h to 25,000 l/h

Culturefuge 400B

- Bactofuge®: continuous solids removal for high concentrations cultures

- For large scale production with capacity from 3,000 l/h to 25,000 l/h

Upon request, Alfa Laval can provide validation support services and a witnessed Factory Acceptance Test (FAT) at our in-house testing facility.

Services

Extending the performance of your equipment

Our dedicated Global Service Network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment. We can work with you to integrate our services into an Alfa Laval Service Agreement for predictable and worry-free operations.

Test, validate, and scale up your next separation solution

Whether upgrading your production line or running a proof of concept, Alfa Laval helps you choose the right separator solution with confidence. Simply get in touch to arrange a consultation and trial at one of our test centres, or to rent a unit for onsite testing.

The Separator Innovator

Would you like to know more about our innovations in separation technology? Click on the link below. Alfa Laval invented the first disc stack separator and has led the way in the development of centrifuge technology for over a century. We are glad to share with you the expertise we have gained along the way. Visit our Separator Innovator knowledge base to learn more about advancements in separation and the steps Alfa Laval is taking to continue revolutionizing the technology.