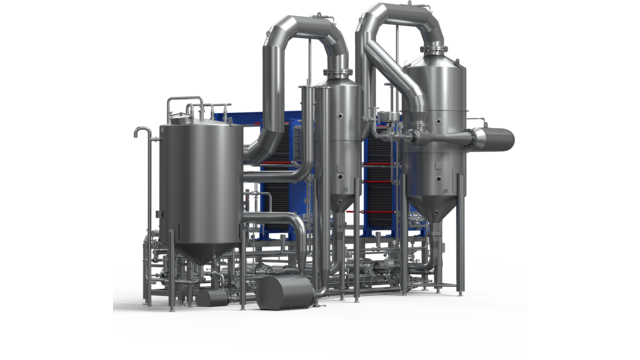

AlfaVap system

The Alfa Laval AlfaVap rising film evaporator concentrates low-to-medium fouling liquids as well as highly viscous liquids across a broad range of applications and industries. Robust, versatile and economical, it is energy efficient, easy to operate and maintain, requiring 50-70% less height than conventional shell-and-tube evaporators. Its compact size makes it easy to install in existing facilities.

More compact, faster start-ups, higher thermal efficiency, and better product quality than shell-and-tube evaporators

- Versatile, economical evaporator for concentration of a various products across a broad range of industries

- Improved product quality due to fast start-up and shut-down times, high heat transfer efficiency, and short residence time – perfect for heat-sensitiv

- High energy efficiency due to lower steam use with multiple effects and thermal and/or mechanical vapour recompression units

- More uptime, less maintenance with minimal fouling due to self-cleaning effect created high turbulence and high shear rate

- Compact, space-saving footprint that is 50-70% shorter in height than shell-and-tube evaporators, reducing installation and service time and costs

Maximize uptime with the Alfa Laval AlfaVap rising film plate evaporator. This cost-effective climbing film evaporator concentrates process liquids that contain dissolved solids, easily handling higher media concentrations and viscosities than tubular evaporators.

Install AlfaVap rising film evaporator as a complete evaporation effect or a cost-efficient booster unit to increase existing evaporator capacity using the existing structures and controls. Its low height makes it easy to install on a single floor with a few or no pumps. This cuts installation costs.

Typical applications of a rising film evaporator include sugar refinery, sweetener, animal and plant-based protein, bioethanol and caustic evaporation duties.

Reduce your engineering requirements with Alfa Laval expertise, global process application development and support, and a complete range of evaporator solutions for a wide selection of applications and capacities. Our complete system designs include vessels, pumps, piping, ducts, instruments, and engineering.

Applications

Take advantage of the unique plate geometry used on the plates of Alfa Laval AlfaVap rising film plate evaporation system. Proven effective since first introduced to the market in the 1990s, the unique semi-welded plate with thick gaskets resulted from close cooperation with sugar manufacturers to improve heat transfer efficiency when concentrating high-viscosity, fouling-prone process liquids.

Food and beverage

- Fruit juices and purées

- Sugars, syrups (corn), honey and confectioneries

- Ethanol stillage

- Meat and vegetable broths

- Gelatine and collagen peptides

- Fermentation products

- Coffee and tea

- Vegetable protein

- Milk and whey protein

- Non-dairy plant drinks (oat, nut, etc.)

- Beer de-alcoholization

- Herbal extracts

Starch and sweeteners

- Sugars (beet, cane, potato, etc.)

- Glucose, dextrose, fructose, maltose

Proteins

- Gelatine

- Stick water

- Meat and fish broths

- Insect protein slurries

- Plant-based proteins

Chemicals and wastewater

- Caustic (NaOH, KOH, LiOH)

- Zero liquid discharge

- Inorganic salts

- Biofuels

Life science/industrial fermentation

- Fermentation broths

- Lysine

- Lactic acids

- Citric acids

- Amino acids

- Yeast extract

How it works

How the AlfaVap rising film evaporator works

The Alfa Laval AlfaVap is a rising thin film plate evaporator. Product flows along the heating channels and evaporates, releasing a portion of its water content. Contact time of the product with the heating surface is limited due to the turbulence and high fluid velocity. The vapour/liquid mixture leaves the plate heat exchangers and enters a vapour separator, which separates the vapour phase and directs it to the upper outlet. The liquid phase collects at the bottom of the separator and is transferred through an outlet for subsequent processing in the next effect or to the final extraction point.

Engineered system

A complete AlfaVap climbing film evaporation system includes plate evaporators, preheaters, cyclone separator vessels, thermal and/or mechanical vapour recompression units, pumps, instruments, valves, ducting and piping and a local programmable logic controller (PLC) and control panel. The system can be pre-assembled in Alfa Laval’s workshop, which reduces installation time on site to one to three weeks.

Sustainability with the AlfaVap rising film plate evaporator

The AlfaVap is highly energy efficient and has a significant and positive impact on sustainability credentials. Watch the video to learn more.

Rising Film Evaporator compared to Shell-and-Tube Evaporator

Compared to a traditional shell-and-tube evaporation system, the AlfaFlash and AlfaVap systems require substantially less installation height and can be installed without complex civil work on site. The AlfaFlash flash evaporator, with its advanced flash evaporation method, offers significant advantages over conventional systems. The compact design of the AlfaFlash plate flash evaporator ensures efficient operation and easy maintenance, making it ideal for various industrial applications.

By utilizing the flash evaporation method, the AlfaFlash flash plate evaporator minimizes fouling and enhances heat transfer performance. This makes it a superior choice for processes involving high-viscosity and high-fouling liquids. The AlfaFlash system's ability to handle challenging process liquids with suspended solids and some crystallization further sets it apart from traditional shell-and-tube evaporators.

Outstanding heat transfer coefficient for the plate evaporator

The Alfa Laval evaporation solutions provide much higher thermal efficiency than traditional shell-and-tube evaporators. With up to three times the heat transfer efficiency versus other technologies, substantial savings can be made, especially at higher concentrations.

Heat sources for evaporation systems

Configuration Options

Alfa Laval evaporation systems can use heat from different sources such as mechanical and thermal compression as well as waste vapours from dryers.

Multiple-effect system

- Saves energy by reusing steam

- Simple and flexible

Mechanical vapour recompression, MVR

- High investment

- Low (or no) steam consumption

- Uses electricity

Thermal vapour recompression, TVR

- Low cost with reduced steam consumption

- Simple, no moving parts

Waste heat from dryers

- Low energy cost

- Relatively high investment

Pilot testing and rentals of evaporation systems

Try before you buy. Get expertise and advice from Alfa Laval engineers for the optimum configuration for your evaporation system, including:

- Detailed water analysis and characterization

- Process and water chemistry modelling

- Benchmark and/or pilot testing for moderate- to high-risk applications

- Detailed material compatibility evaluation

- Sample analysis

- Pilot tests

Visit the Alfa Laval Materials Technology & Chemistry Lab and Test Centre in Lund, Sweden, the Alfa Laval Innovation and Test Centre in Nakskov, Denmark, or rent one of our mobile pilot evaporation systems to conduct onsite trials at your plant.

Fossil free concentration process

A lot of water is transported on our roads today, and by reducing the water content in food products using an evaporation system, you will reduce the energy consumption in transportation.

The concentration step is often the highest energy consumer in your processing plant. With the AlfaVap Inline, you can reduce the energy required for your concentration process by shifting from fossil fuels to electrical energy. This makes it possible to achieve a fossil free energy solution for concentration, significantly reducing carbon emissions and lowering operational costs.

Watch our webinar: Learn how you can produce more food and beverages while using less water and emitting less carbon.

Happy customers

Service

Food system services

Alfa Laval Food system services help extend the performance of your food systems by maximizing the performance of your processes. This enables you to:

- Continually improve your operations to maintain competitive advantage

- Focus on uptime, optimization and availability

- Maximize return on investment throughout the life cycle of your food systems

Learn more about our service offer for food systems

You might also be interested in...

Explore our range of evaporators

Alfa Laval offers a wide range of evaporation systems from plate evaporators, and rising film evaporators to tubular evaporators and falling film evaporators. Find out what would work for your evaporation needs.