ESA, ATD and End plug devices

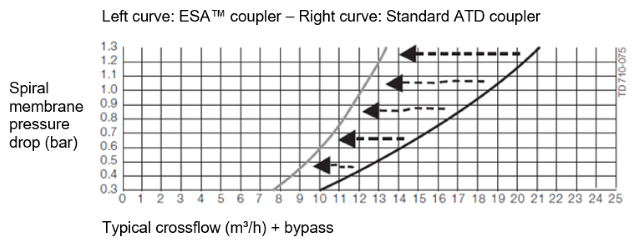

The energy saving ESA™ device, ATD coupler and end plug from Alfa Laval are used to interconnect and support the spiral membranes in the housing. The ESA™ device further effectively reduces the non-productive by-pass between the spiral membranes and the housing. This makes you save up to 30% of the energy consumption

ESA™ coupler

The special Alfa Laval developed and patented Energy Saving Anti-telescoping ESA™ coupler makes you reduce the overall energy consumption of your membrane plant.

This is done as the ESA™ coupler effectively reduces the non-productive by-pass between the spiral membranes and the housing. An example is an ultrafiltration loop where you can save up to 30% energy with no negative impact to the membrane crossflow. Or it allows you to extend a membrane lop with no extra costs for additional spiral membranes.

The Alfa Laval ESA™ coupler is available in stainless steel (SS) or polyphenylene sulfide (PPS) for 6.3" and 8.0" UF and RO spiral membranes. The ESA™ coupler also comes as a boxed ESA Kit™ which includes an ESA™ coupler and fitting o-rings.

ATD coupler

The purpose of the Alfa Laval Anti Telescoping Device (ATD) is to transport the permeate through the spiral membranes to the discharge port of the housing. The ATD coupler also prevents the spiral membranes from telescoping.

The Alfa Laval ATD coupler is available in SS for UF and RO spiral membranes of the sizes 6.3", 8.0" and 8.3". Couplers made of PPS are available for 2.5" and 3.8" spiral membranes.

A special transition ATD coupler in SS is available for connection between 28.58 mm and 28.9 mm permeate tubes.

End plug

The Alfa Laval end plug is mounted at the front of the first spiral membrane in the housing with the purpose to prevent the feed flow from entering the permeate collecting tube.

Benefits, auxiliary membrane equipment

- wide range of special ancillary equipment, fittings and accessories

- full spectrum available from one single expert source

- short delivery times and efficient logistics

- all components dovetailing perfectly

- all materials in compliance with FDA regulations and suitable for food and pharmaceutical applications

How it works

Customized solutions through flexible design

Alfa Laval membrane filtration equipment is designed on a modular basis that gives a high degree of flexibility, as spiral membranes are mounted into housings, housings are built into loops, and loops are built into systems. The design of a system can thus be customized to meet any process needs and it is easy to expand, if production requirements increase. This means that your investment can follow any required increase in production capacity, as and when you need it - and at relatively low additional cost.

Compliances

All materials used for the production of Alfa Laval membranes, in both spiral-wound and flat-sheet membrane designs and configurations, comply with EU Regulation (EC) 1935/2004, EU Regulation 10/2011, EU Regulation (EC) 2023/2006 and FDA regulations (CFR) Title 21. The membranes are thus suitable for use within food and pharmaceutical processing applications.

These compliance also extend to the equipment and fittings related to membrane operations, including items such as plate-and-frame units, element housings and pumps.