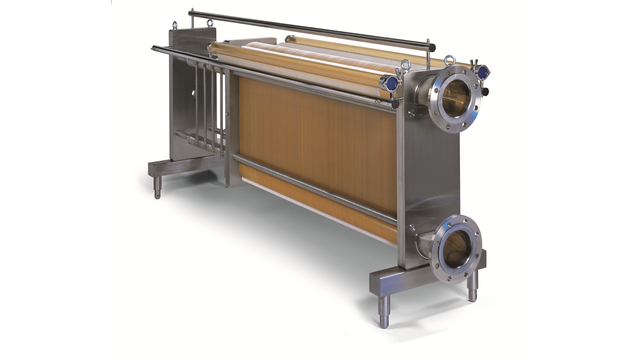

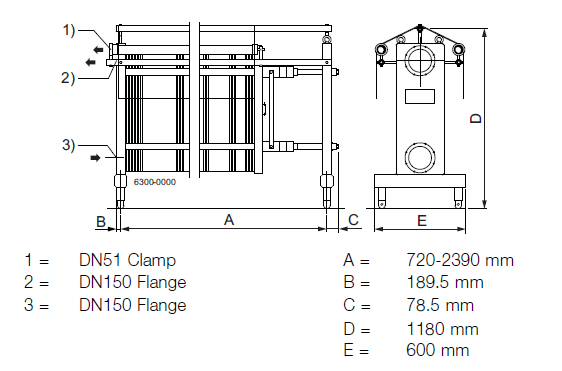

Module M39L/H

The M39L/H is one of the most popular plate-and-frame modules from Alfa Laval. A special design makes the module an excellent choice for ultrafiltration and microfiltration of high-viscous products (1-30 cP) and fermentations broths within the biotech and pharma industries as well as for food and beverage applications. It is developed to meet the future demands for optimized flow dynamics, low energy consumption and low pressure operation.

Improved products and processes

Ultrafiltration (UF) is unique in that it allows liquids to be separated, concentrated and purified, all at the same time. Water and low molecular-weight substances pass through the membrane whilst high molecular-weight substances are rejected.

The composite structure of our microfiltration (MF) and ultrafiltration (UF) membranes, consisting of a support layer for mechanical strength and a thinner selective layer for the separation, combines the best of two worlds: High mechanical strength and a high capacity/flux.

Plate-and-frame module, M39L/H

The M39L/H module from Alfa Laval is a popular choice within the biotech and pharma industries, where it is used with great success for the processing of antibiotics, amino acids/organic acid, dextranes and industrial fermentation. Also for food and beverage applications such as dairy, gums, sugar etc. the module is widely used.

The M39L/H module is developed to meet the future demands for optimized flow dynamics, low energy consumption and low pressure operation. It is available with plates having low (L) or high (H) channels and in various standard sizes defined by a membrane area up to max. 60 m².

The module operates at temperatures up to 80°C, pressures up to max. 8 bar and pH between 1-14 bar. It can be equipped with the entire range of flat sheet ultrafiltration and microfiltration membranes available from Alfa Laval.

Benefits

Compared to previous module types, the M39 module from Alfa Laval offers:

- up to 30% reduction in energy consumption

- up to 30% increase in flux

- up to 6 times bigger section sizes

- all in all reduction of system price by 10-30%

- approx. 1.5 times reduction in operation pressure

- up to 15% increase in concentration degree

- approx. 1.5 times bigger module sizes

How it works

Design

The plate-and-frame module from Alfa Laval is designed with open channels across the membrane surface. The feed stream/retentate flows through these.

The membrane itself is supported by hollow plates with numerous slots that allow the permeate to collect and be removed from the module via the permeate collecting tubes.

Plate-and-frame modules use the membrane itself, aided by lock rings or strips, to seal off the feed/retentate from mixing into the permeate channels. This also prevents any leaks from the plate stack itself.

Due to the design of the plate-and-frame modules from Alfa Laval, individual membranes can be replaced without affecting the other membranes of the module.

Due to the design of the plate-and-frame modules from Alfa Laval, individual membranes can be replaced without affecting the other membranes of the module.

Customized solutions through flexible design

Alfa Laval membrane equipment is designed on a modular basis that gives a high degree of flexibility, as membranes are built into modules, modules are built into loops and loops are built into systems.

The design of a system can thus be customized to meet any process needs and it is easy to expand, if production requirements increases. This means that your investment can follow any required increase in production capacity, as and when you need it - and at a relatively low additional cost.