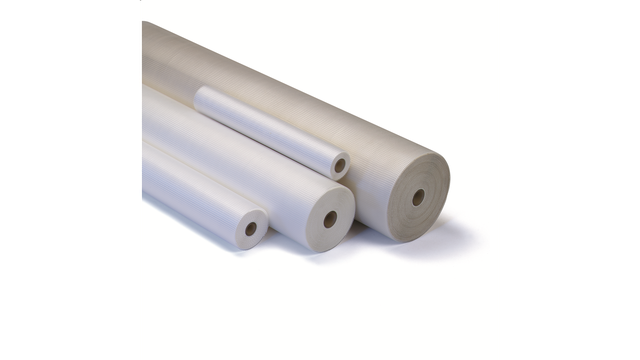

RO spiral

Alfa Laval reverse osmosis spiral membranes (RO) are low energy, proven solutions for concentrating feed streams, particularly heat sensitive products. The RO spiral membranes can also be used for pre-concentration prior to evaporation as well as product and water recovery from permeate streams and evaporator condensate. The two series of RO membranes have different NaCl rejection properties. The RO membranes are thin-film composite cast on either polyester or polypropylene backing paper.

Proven design and membrane technology to enhance your RO process

- Cost effective operation thanks to low energy consumption

- Efficient – covering a broad range of salt permeabilities

- Minimal floor space required with its compact design

- Extremely durable – excellent chemical and thermal stability with service life up to several years

- Flexible – available in different combinations of length, diameter and spacer size

About our reverse osmosis membrane range

The minuscule pores of Alfa Laval RO membranes only allow small fractions of salts to pass through along with the water, the prime component of the permeate. Certain organic compounds with low molecular weights may also pass through but only to a limited extent. However, the membrane will retain for any other components (salts, sugars, etc.) suspended or dissolved within the liquid flow.

RO PE Series

The RO spiral membranes of the RO PE series, RO99 and RO90, have a NaCl rejection of ≥98% and ≥ 90% respectively.

RO98 pHt™ Series

RO98 pHt™ Series

This version has a pHt™ spiral membrane that tolerates temperatures and pH higher than the RO PE series. The RO98 pHt™ has a NaCl rejection of ≥ 98%.

All types are USDA approved and we can offer products with Halal certificates upon request.

Our RO spiral membrane materials are compliant with all major regulations

Our spiral wound membrane materials are compliant with all major regulations

All membrane materials used for both flat sheet and spiral wound membrane configurations meet EU Regulation (EC) 1935/2004, EU Regulation 10/2011, EU Regulation (EC) 2023/2006 and FDA regulations (CFR) Title 21, and are suitable for use in food and pharmaceutical processing applications. Compliance also extends to the related equipment and fittings, including items such as plate-and-frame units, element housings and pumps, supporting safe and efficient spiral membrane filtration in a wide range of industries.

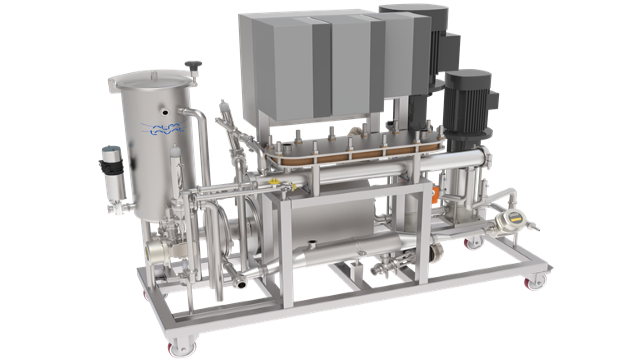

How it works

The basic technology behind membrane filtration involves using a semi-permeable membrane to separate a liquid into two distinct streams.

Pumping this liquid across the surface of the membrane creates a positive trans-membrane pressure that allows any components smaller than the porosity of the membrane to pass through, forming the permeate.

Any components larger than the pore size simply cannot pass through, and remain behind in what is called the retentate. The surface of the spiral wound membrane is kept free of blockages by the force of the liquid flow moving parallel to the membrane surface.

Construction of the RO spiral membrane

Efficient spiral membrane filtration

A spiral membrane comprises of several membrane 'envelopes' with two membrane sheets separated by a permeate spacer mesh, each glued to a central permeate collection tube.

Between each pair of envelopes there is a spacer which creates the feed channel, allowing the feed to flow across the length of the spiral wound membrane, whilst the permeate passing through the membrane into the membrane envelope flows in a spiral pattern to the permeate collection tube.

Red = Feed/retentate.

Green = Permeate.

The flow pattern in an RO spiral membrane where red represents the feed/retentate and yellow the permeate.