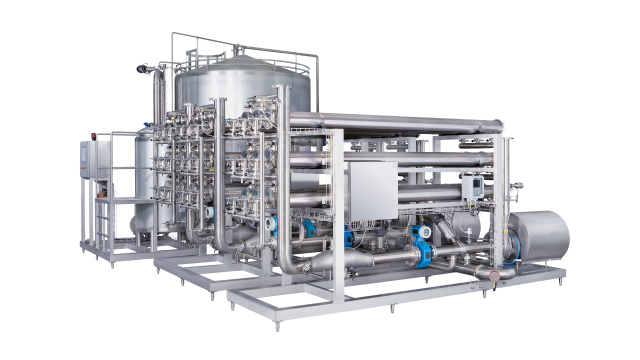

Top ten tips for membrane solutions

How to keep your membrane solution in tip top condition

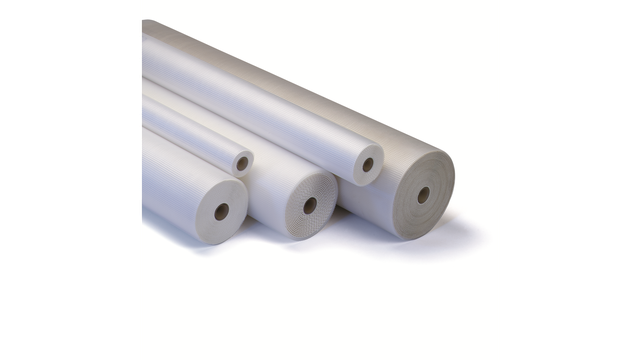

- Plan maintenance intervals and use genuine Alfa Laval membranes and parts

- Secure data logging of the plant to identify trends and areas for improvement

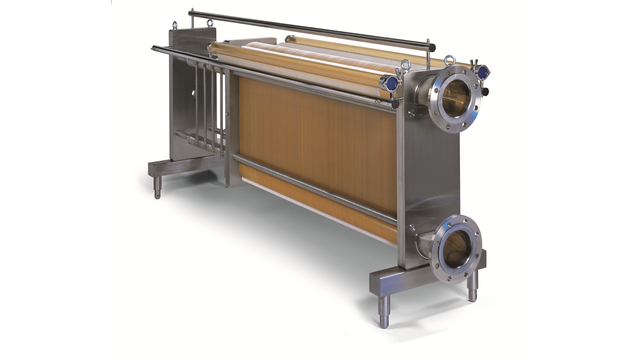

- Ensure sufficient pre-treatment of the feed to be processed

- Keep the membranes moist and add a preservative solution during shutdowns

- Ensure that operating conditions remain within the recommended limits of the membranes

- Avoid permeate back-pressure and any abrupt cross-flow, pressure, or temperature variations

- Minimize the increase of operating pressure for MF and UF, to avoid premature fouling

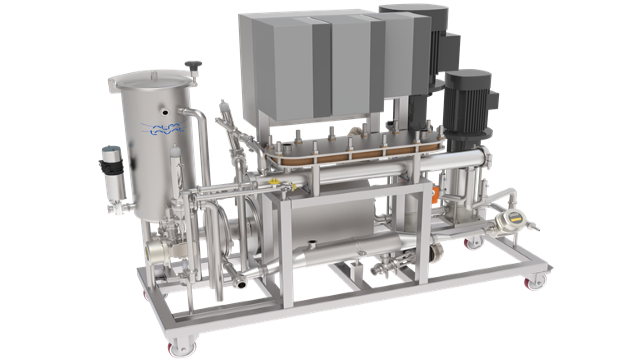

- Start Cleaning-in-Place (CIP) based on low capacity or high pressure thresholds; monitor CIP efficiency (water flux)

- To save chemicals and water, check the condition and dosing of cleaning agents

- To help boost output and quality, consider plant audits by Alfa Laval experts